6A–48 ENGINE MECHANICAL

15.Remove the injection pipe oil seal.

Inspection and Repair

Make the necessary adjustments, repairs, and part

replacements if excessive wear or damage is

discovered during inspection.

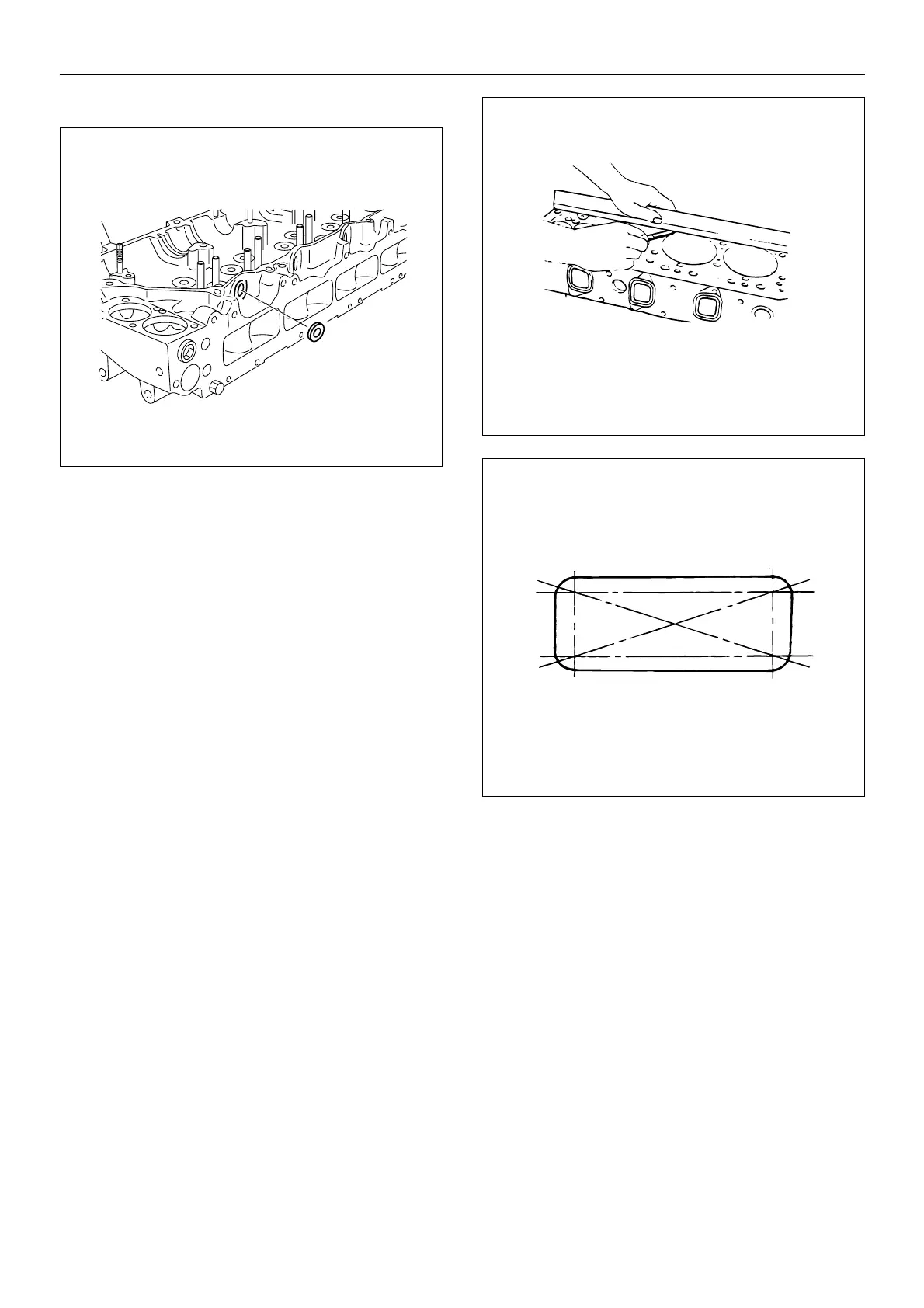

Cylinder Head

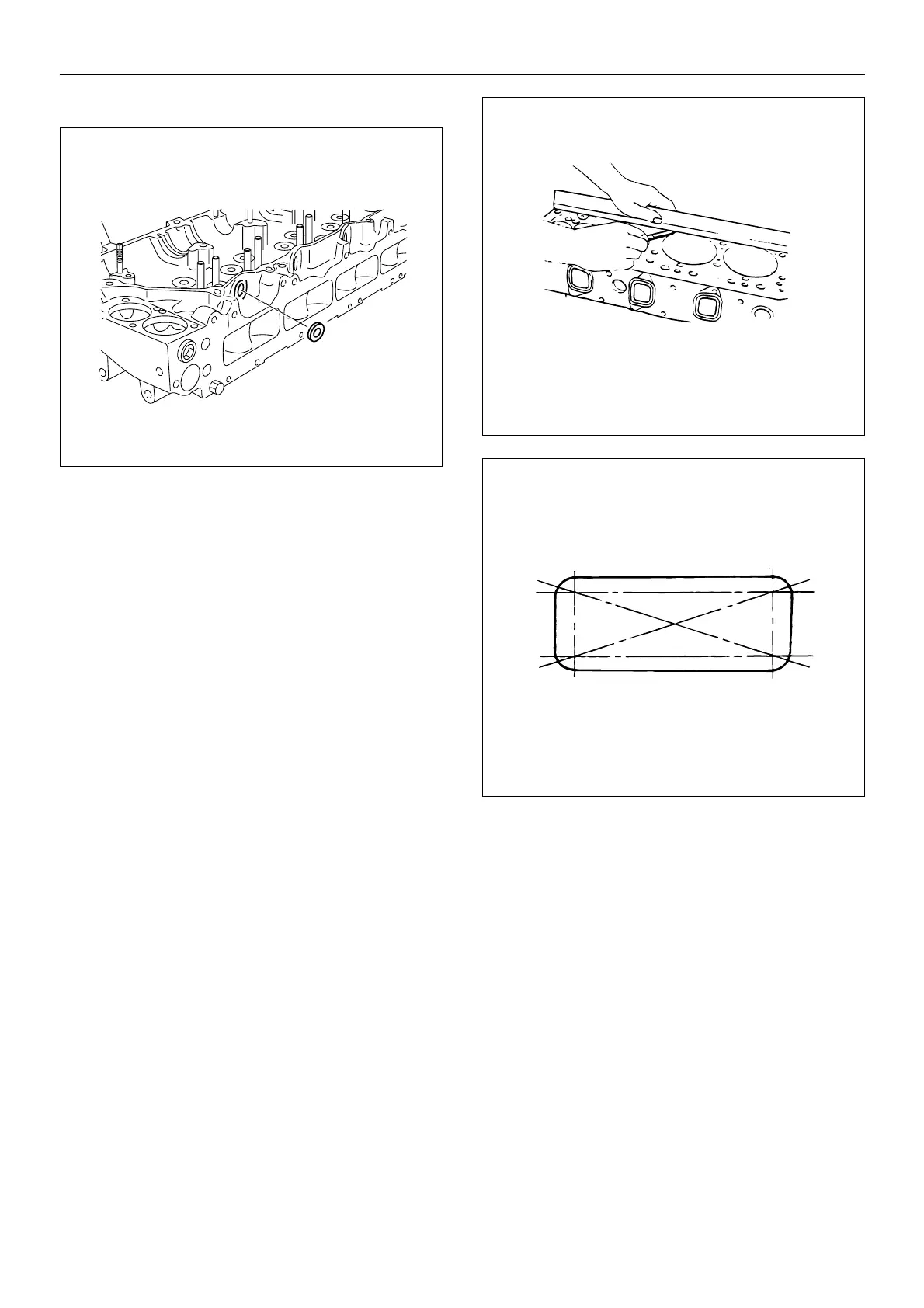

Cylinder Head Lower Face Warpage

Use a straight edge and a feeler gauge to measure the

four sides and the two diagonals of the cylinder head

lower face.

If the measured values exceed the specified limit, the

cylinder head must be replaced.

Cylinder Head Lower Face Warpage

Standard: 0.05 mm (0.002 in) or less

Limit: 0.20 mm (0.008 in)

NOTE: Do not attempt to regrind the cylinder head lower

face.

Check the cylinder head lower face for cracking and

other damage.

Valve Guide

Valve Stem and Valve Guide Clearance

Measuring method-I

1. Insert the valve to the cylinder head.

2. Set the dial indicator to the valve stem at measuring

point as shown in the illustration.

Measuring Point: 10 mm (0.4 in)

3. Set the dial indicator needle to “0”.

4. Move the valve head from side to side.

Read the dial indicator.

Note the highest dial indication.

If the measured values exceed the specified limit, the

valve and the valve guide must be replaced as a set.

Valve Stem Clearance

Intake Valve

Standard: 0.04 – 0.06 mm (0.0016 – 0.0024 in)

Limit: 0.20 (0.008 in)

011MX026

011EY00066

Loading...

Loading...