3.3.1 Alignment checks

Initial Alignment (Cold Alignment)

•

Before Grouting Baseplate - To ensure alignment can be obtained

• After Grouting Baseplate - To ensure no changes have occurred during grouting process

• After Connecting Piping - To ensure pipe strains haven’t altered alignment. If changes have occur-

red, alter piping to remove pipe strains on mixer flanges

Final Alignment (Hot Alignment)

After First Run - To obtain correct alignment when both mixer and driver are at operating temperature.

Thereafter, alignment should be checked periodically in accordance with plant operating procedures.

3.3.2 Alignment criteria

Good alignment is achieved when the dial indicator readings as specified in the alignment procedure

are .05 mm (.002 in.) Total Indicated Reading (T.I.R.) or less when the mixer and driver are at operating

temperature (Final Alignment).

During the installation phase, however, it is necessary to set the parallel alignment in the vertical direc-

tion to a different criteria due to differences in expansion rates of the mixer and driver. For Model 3501,

the Cold Setting of Parallel Vertical Alignment table shows recommended preliminary (cold) settings for

electric motor driven mixers based on different pumpage temperatures. Driver manufacturers should be

consulted for recommended cold settings for other types of drivers (steam turbines, engines, etc.).

Table 2: Cold Setting of Parallel Vertical Alignment

Cold Setting of Parallel Vertical Alignment

Fluid Temperature Set Driver Shaft

10°C (50° F) .05 mm (.002 in.) Low

65°C (150°F) .03 mm (.001 in.) High

120°C (250°F) .12 mm (.005 in.) High

3.4 Set up

1.

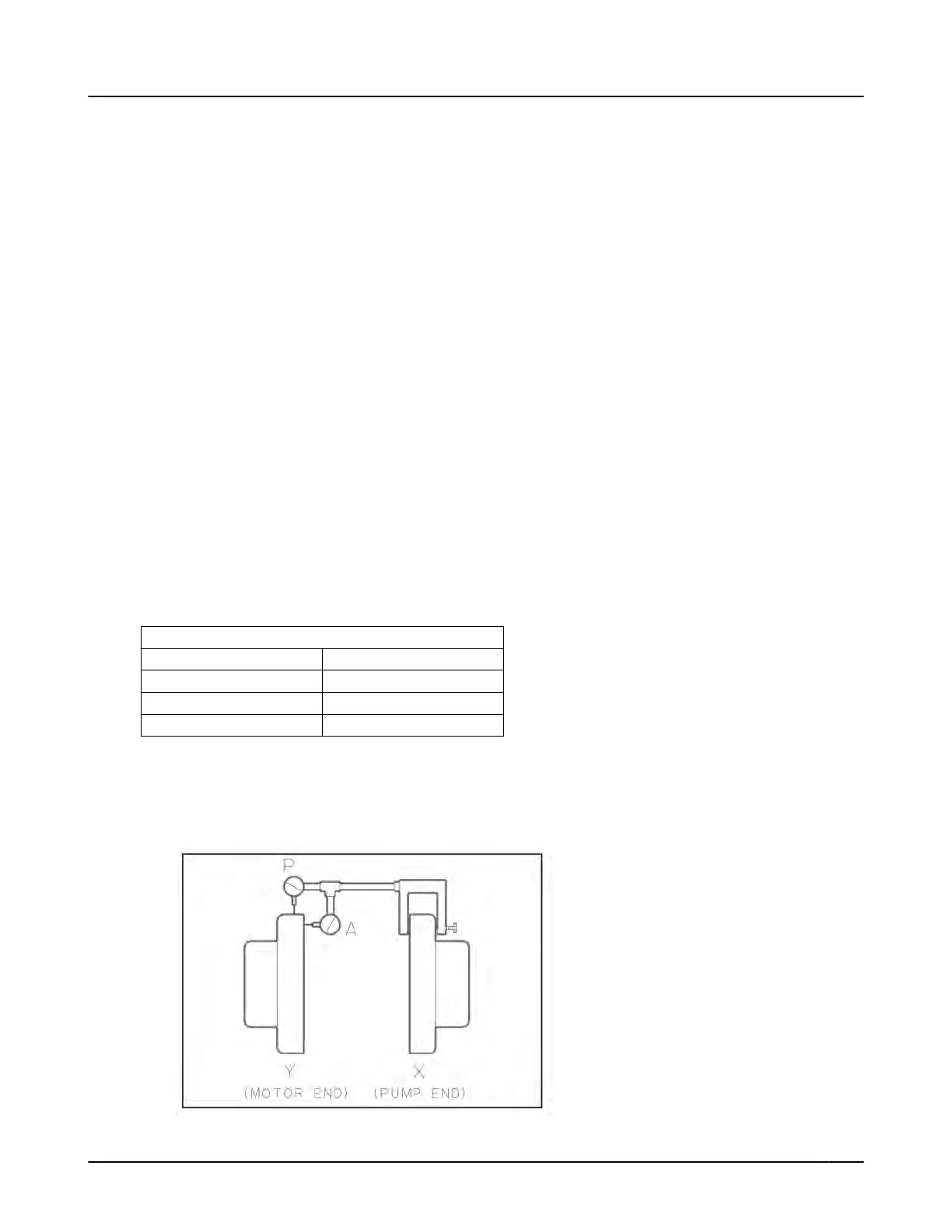

Mount two dial indicators on one of the coupling halves (X) so they contact the other coupling half

(Y), see Figure 11: Dial indicator mounting on page 15.

Figure 11: Dial indicator mounting

3.4 Set up

3501 Installation, Operation, and Maintenance Instructions 15

Loading...

Loading...