13

Initial Operation and Maintenance

WARNING

BE CERTAIN THAT ALL POWER IS SHUT OFF BEFORE SERVICING THE GRAIN CART.

Before the grain cart is put into service:

Have the safety instructions been read and clearly understood by the operator(s) of this machine?

Has the gearbox been properly lled with SAE 80W-90 gearbox lubricant?

Have all nuts, bolts, bearings and braces been properly fastened?

Has the PTO been checked for proper overlap?

IMPORTANT: Has the slip clutch on the PTO been serviced? If the slip clutch is left unchecked, damages to the power-take-o

and drive shaft may result. Before using the grain cart, loosen the bolts around the slip clutch. Make sure the friction plates turn

free of each other and are not corroded together. Re-tighten the tension bolts. Run the auger system EMPTY and check for proper

engagement of the slip clutch.

CHECK PTO OVERLAP LENGTH. Overlap length may vary depending on the tractor model and hitch setting. Try to obtain the

greatest possible overlap without bottoming out in the extreme operating conditions. Too much overlap may cause the PTO to

bottom out and damage the driveline. Not enough overlap may cause the PTO front and back halves to separate. From the fully

compressed (shortest) length the PTO should be telescoped (extended) between 10” and 22”. Dierent PTO lengths may need

to be purchased to accommodate your terrain. A 4” shorter or a 10” longer PTO can be ordered through your dealer from J&M

Manufacturing.

GREASE BEARINGS: Are all bearings on the drive line properly greased? Are all set screws in the bearings and U-joints tight? Has

the power-take-o shaft been properly greased at all points including the cross bearings? Has the universal joint at the gearbox

been greased? Have all grease points at the auger hinge area, including the hanger bushing assembly been greased?

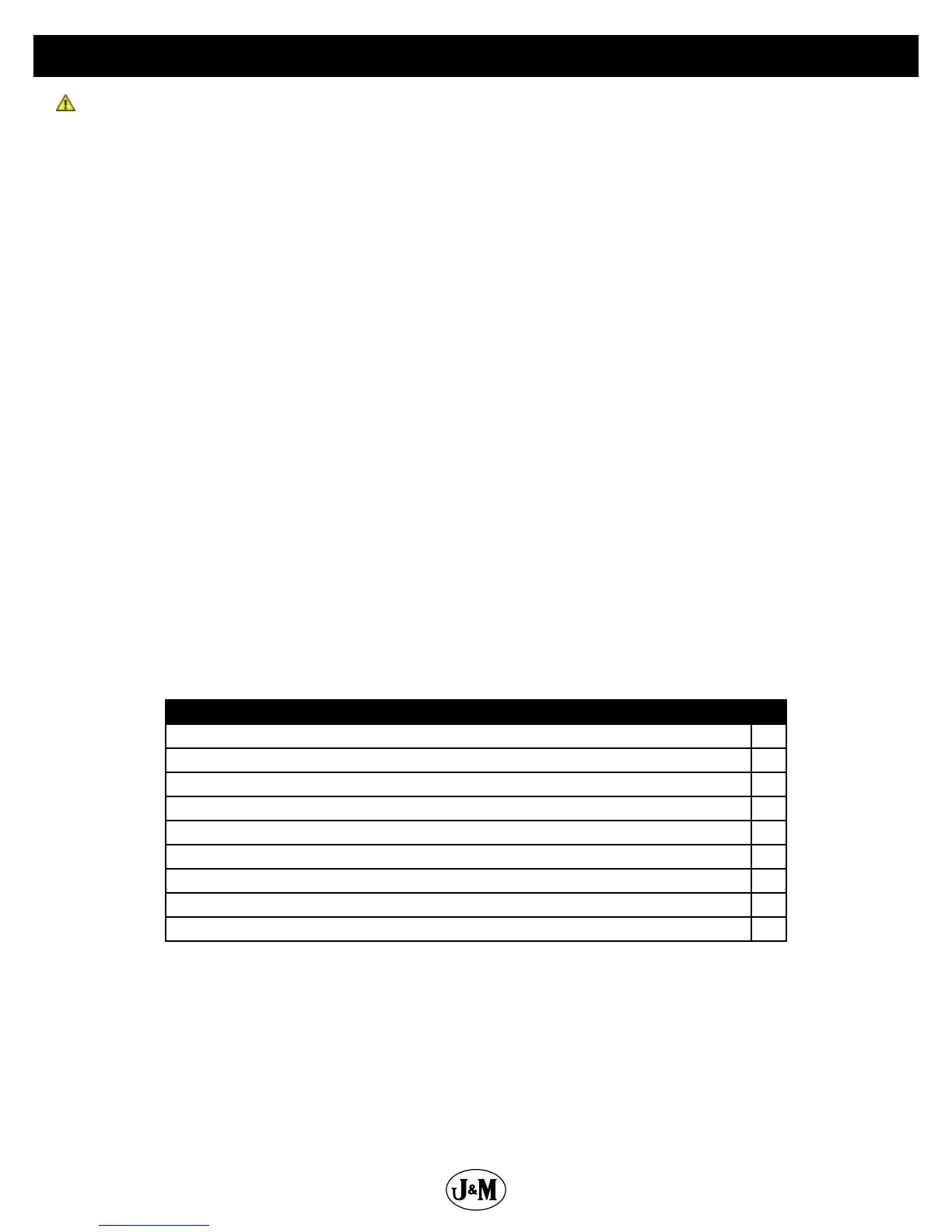

TIRE PRESSURE: Are the tires properly inated? The following is to be used as a general guide for tire ination for cyclic use.

Figures can vary depending on specic brand of tire used. It is important that tires are inspected before and after the unit is

loaded. The tire should stand up with no side wall buckling or distress as the tire rolls. Do Not Exceed The Tire Pressure

Indicated Below:

Tire psi

900/60R32 Lug Tires (Firestone) (176LI) (for 30x32-10 Hole Wheels) (136” c/c) 41

900/60R32 Lug Tires (Alliance) (176 LI) (for 30x32-10 Hole Wheels) (136” c/c) 66

35.5x32 Diamond Tires-20 ply (Firestone) (for 31x32-10 Hole Wheels) 26

1050/50R32 Lug Tires (Alliance) (185 LI) (for 32x36-10 Hole Wheels) 56

480/80R42 Lug Tires (Firestone) (154 LI) (for16x42-10 Hole Wheels) 35

480/80R42 Lug Tires (Alliance) (169 LI) (for16x42-10 Hole Wheels) 64

IF520/85R42 Lug Tires (Firestone) (169 LI) (for 18x42-10 Hole Wheels) 44

520/85R42 Lug Tires (Alliance) (169 LI) (for 18x42-10 Hole Wheels) 50

IF1250/50R32 Lug Tires (Firestone) (188 LI) (for 44x32-10 Hole Wheels) 23

Loading...

Loading...