16

Lubrication Service Schedule

IMPORTANT: Your grain cart has grease ttings at all critical points. These should be serviced before the grain cart is put into

operation.

WARNING

BE CERTAIN THAT ALL POWER IS SHUT OFF BEFORE SERVICING THE GRAIN CART

PTO & DRIVELINE: The grease ttings on the PTO should be serviced after every 8 hours of use. Service the grease ttings on each

of the drive bearings and also the universal joint after every 8 hours of use.

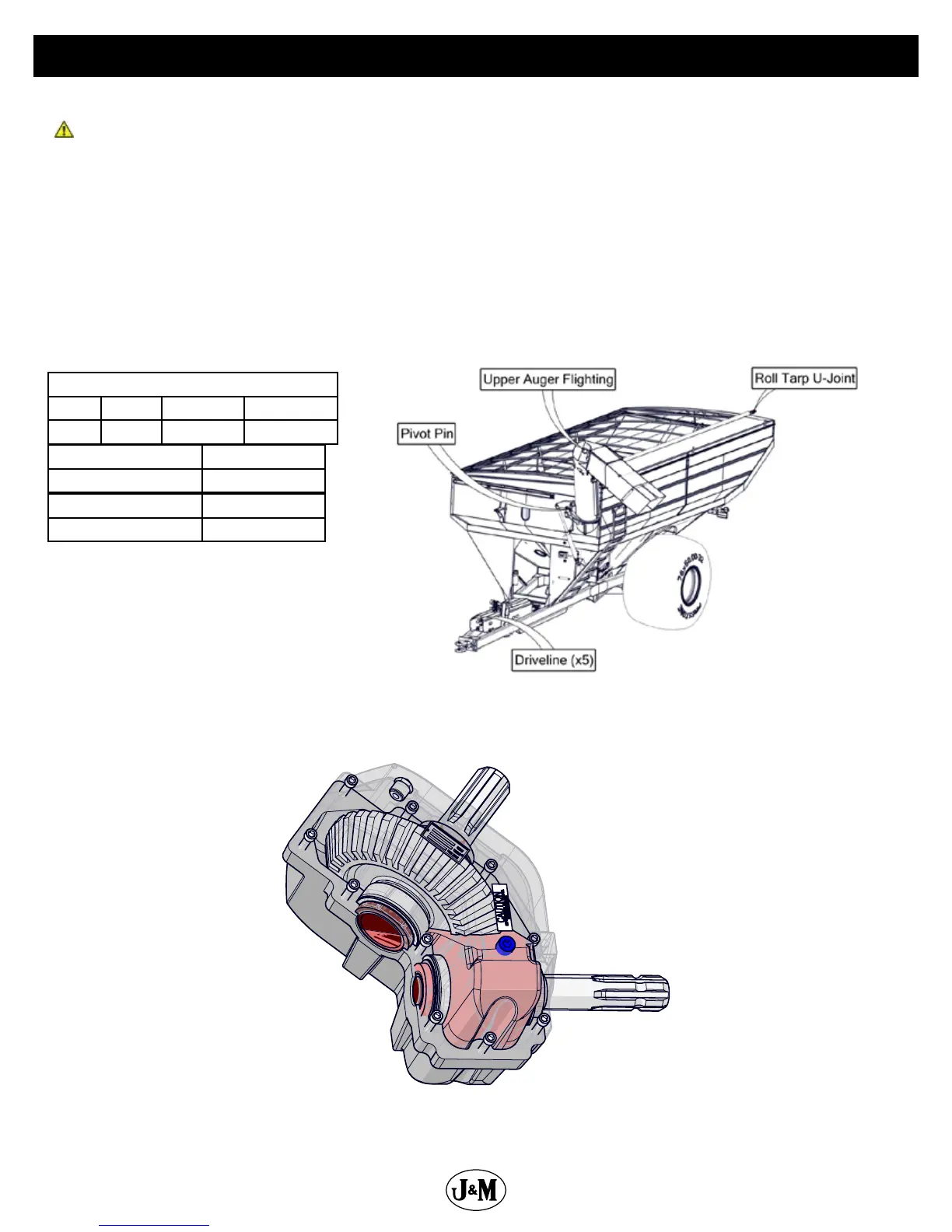

AUGER FOLDING MECHANISM: One grease tting is located on the pivot pin of the folding auger. This tting should be serviced

after every 8 hours of use. Service the grease tting on the hanger bushing assembly (top end of the lower auger assembly) after

every 8 hours of use or as needed.

SPRING LOADED UPPER AUGER BEARING: Service the grease tting on the upper auger bearing (located at the top end of the

upper auger assembly) after every 8 hours of use. Lubricate the springs and retaining bolts on the bearing before prolonged

storage of the grain cart.

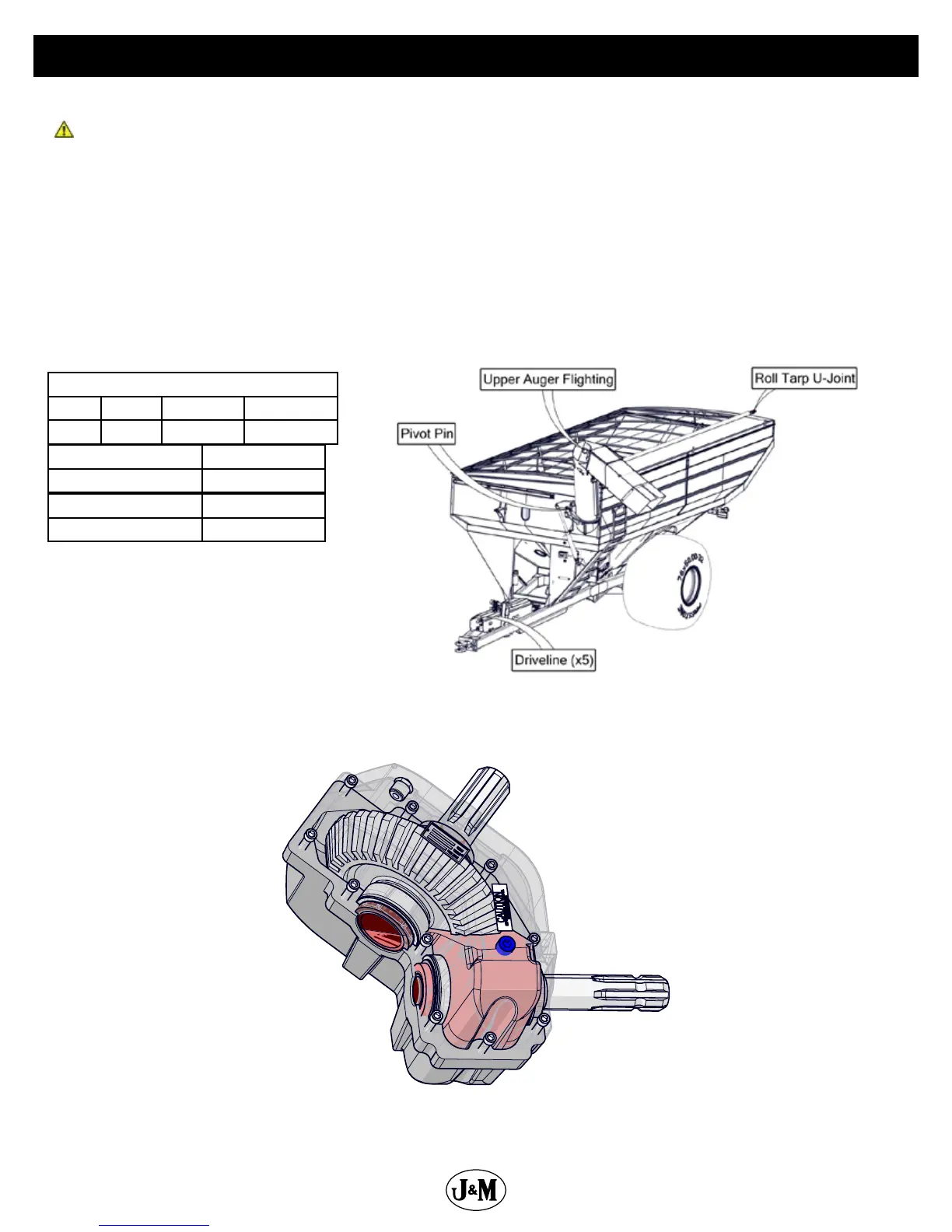

GEARBOX: Gearbox lubricant has been added to the gearbox during nal assembly. Recheck the lubricant level before initial operation

of the grain cart, then periodically according to use. The uid level should rest at the inspection plug, pictured in blue below. When

lled to the proper level, the gearbox should have 96 ounces of

SAE 80W-90 lubricant. Change the oil annually before use.

Pivot Pin Once Annually

Roll Tarp U-Joint Once Annually

Gearbox Lubricant

Model Ounces Input Sha Output Sha

1012 96 1-3/4” 2”

Upper Auger Flighting Every 8hrs of use

Driveline Every 8hrs of use

Loading...

Loading...