Page 39

6.2.5 Selection and adjustment of welding parameters

The master encoder can switch and adjust all parameters. If the numbers or options on the

LCD screen display green, it indicates the parameter can be adjusted with the master

encoder; if they display gray, it indicates the parameter cannot be adjusted.

1. Adjustment of main welding parameters

In the welding working page, the current, wire feed speed and voltage can be adjusted by

rotating three knobs, respectively.

In MIG mode, knob A can adjust the welding current or wire feed speed, knob B can adjust the

welding voltage or arc length, and the master encoder can adjust all parameters. Pressing

the master encoder can switch the parameters.

In MMA or Lift TIG mode, the current can only be adjusted by the master encoder.

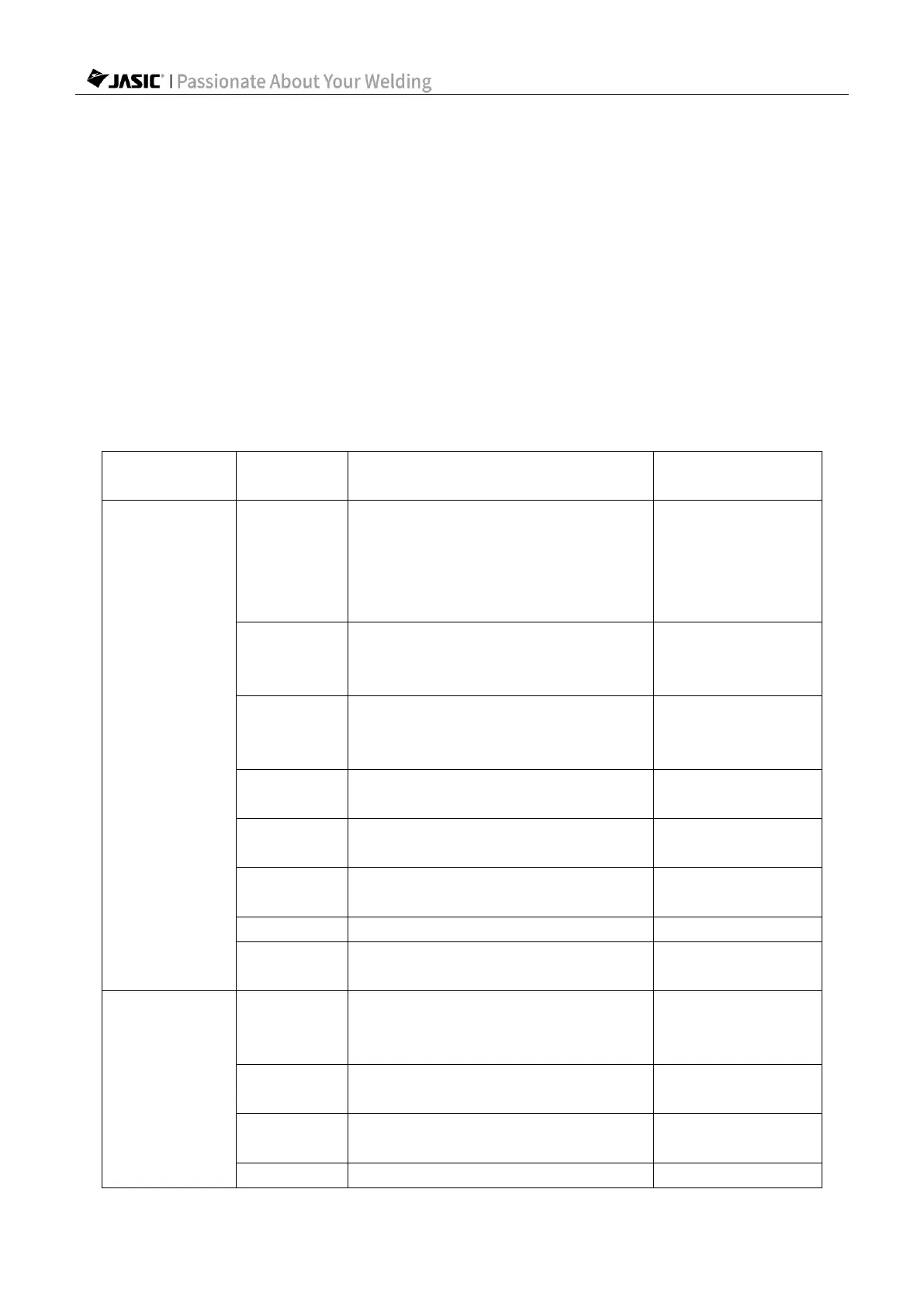

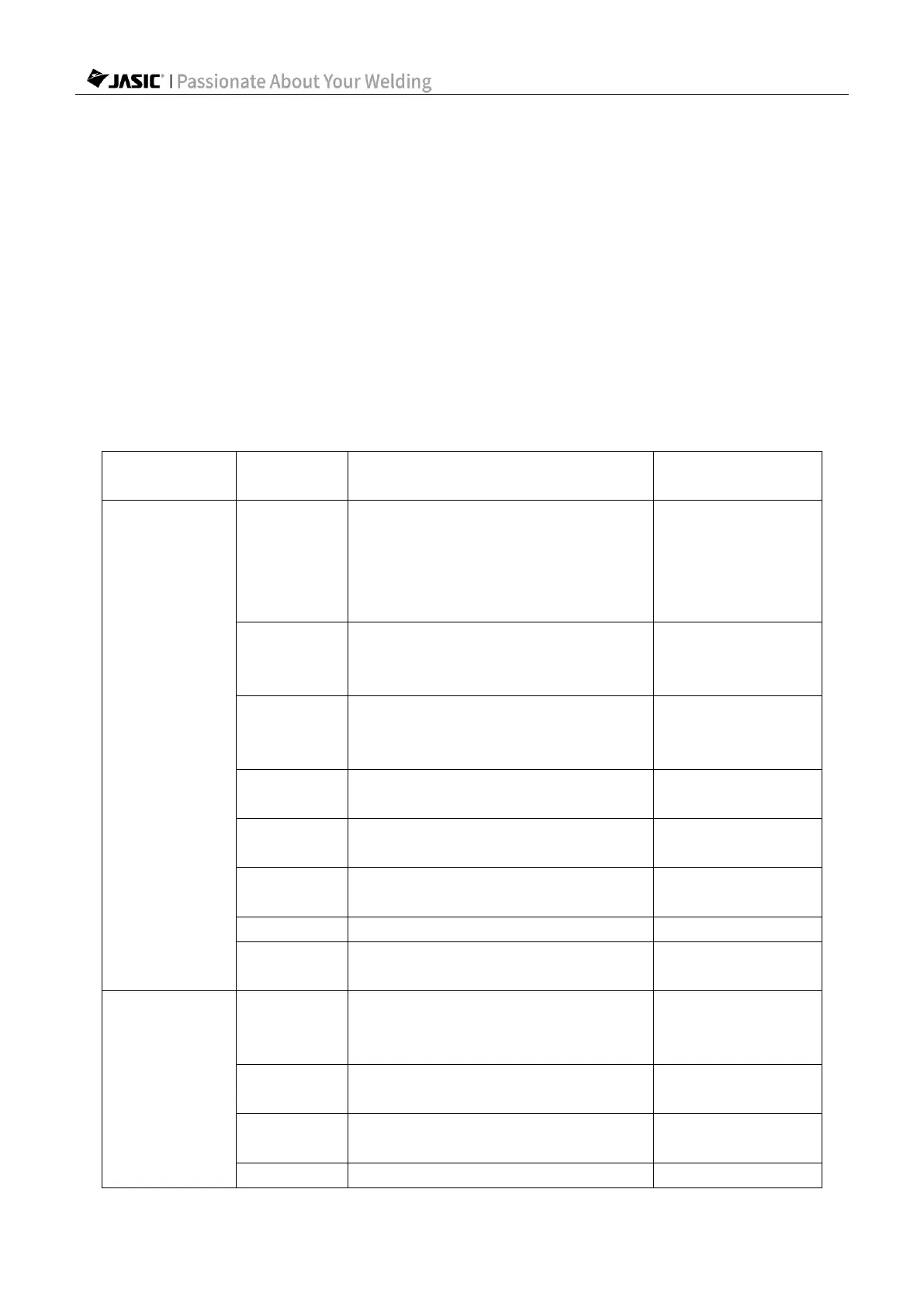

2. Adjustment of other welding parameters

Except for current and voltage, all other parameters can only be adjusted in "Parameter

Settings", which are detailed in the following table:

Loading...

Loading...