8 - 12

All tapped holes and gasket faces should be thoroughly

degreased by washing as liquid packing and adhesive is

used on all gasket surfaces and threads.

Apply adhesive to the final few threads of a bolt or screw. Do

not apply excessive amounts of adhesive. Wipe off any

surplus.

Leave the unit for at least twelve hours after assembly to

allow the adhesive to fully dry.

Ensure that all components are re-fitted to the positions from

which they were removed, paying particular attention not to

intermix components from identical sets front and rear.

Section F Transmission

9803/6410

Section F

8 - 12

Issue 1

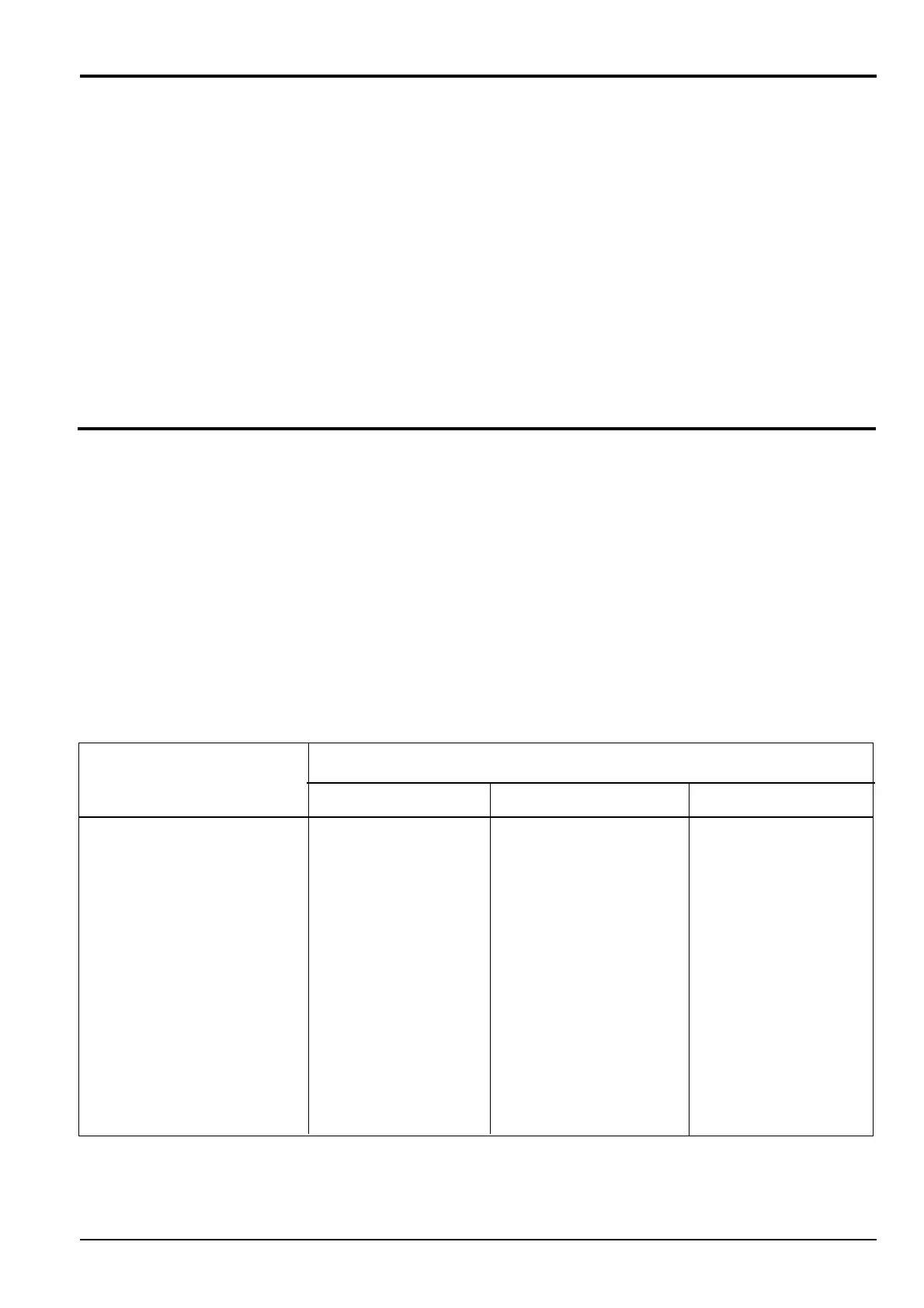

Traction Motor

Torques

Part

Nm lbf ft kgf m

Plug 121 58 ± 10 43 ± 7 6 ± 1

Plug 124 333 ± 49 246 ± 36 34 ± 5

Plug 126 133 ± 19 98 ± 14 13.5 ± 2

Socket head bolt 143 163 ± 24 120 ± 18 16.6 ± 2.5

Connector 188 98 ± 19 72 ± 14 10 ± 2

Sleeve 202 127 ± 19 94 ± 14 13 ± 2

Plug 204 80 ± 19 59 ± 14 8 ± 2

Plug 214 98 ± 19 72 ± 14 10 ± 2

Plug 215 30 ± 5.4 22 ± 4 3 ± 5

Assembly

Clean each part in a suitable solvent and dry using

compressed air.

Inspect all parts and renew as required.

Care must be taken not to let dust or dirt adhere to parts

after cleaning and that parts do not become dented,

scratched or damaged.

Fit new ‘O’-rings, plugs, packing, oil seals and fastener

seals.

Apply Lithium grease to all new oil seals (particularly the lip

areas) and ‘O’-rings, and clean hydraulic fluid to all sliding

parts before installation.

When Assembling

Assembly is the reverse of dismantling, but note the

following points:

1 When installing the cylinder block assembly into spindle

2 take care not to touch the housing. Carefully align the

recesses in swash plate 103 with the steel balls 167

(pivots 167 on JS160) already installed in the housing.

When the motor is fully assembled, rotate the cylinder

block and check for freedom from backlash. If backlash

is present, inspect and take remedial action.

2 Tighten the plugs, etc to the torques indicated below.

Loading...

Loading...