3 - 19

Section E Hydraulics

9803/6020

Section E

3 - 19

Issue 1

Schematics

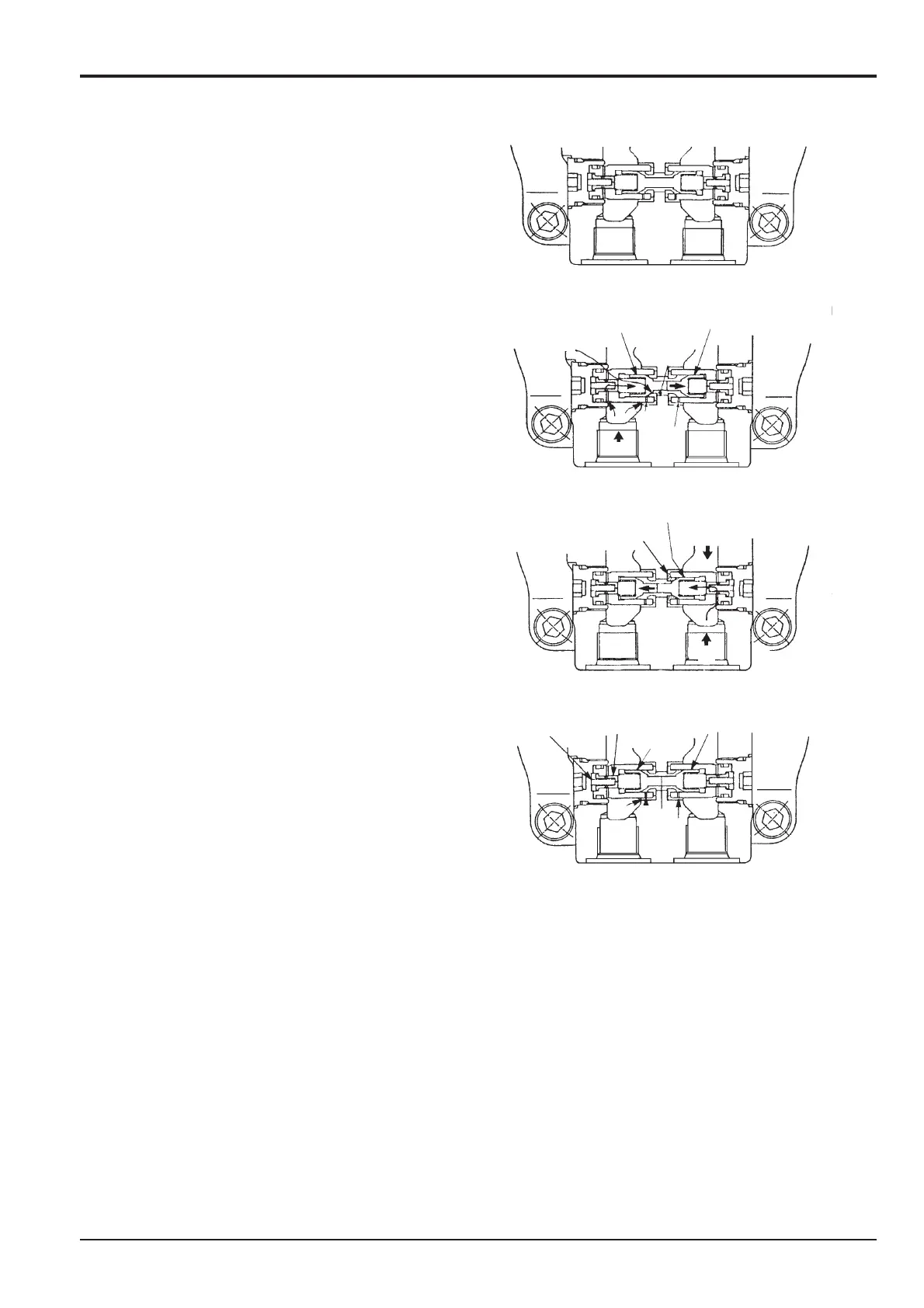

Swing Over-run Prevention Operation

The swing over-run prevention valve is installed inside

the swing motor to prevent the swing back when the

swing is stopped.

1 No swing (Figure 1)

The swing over-run prevention valve is in neutral state.

2 Swing acceleration, during swing (Figure 2)

When operating the swing, port H and port J are

connected through the small hole E the intermediate

chamber D and the small hole F. The oil flows out of port

J immediately. The high pressure oil enters into the back

chamber of the poppet B. This causes the poppet to

move towards the right side as in figure 2

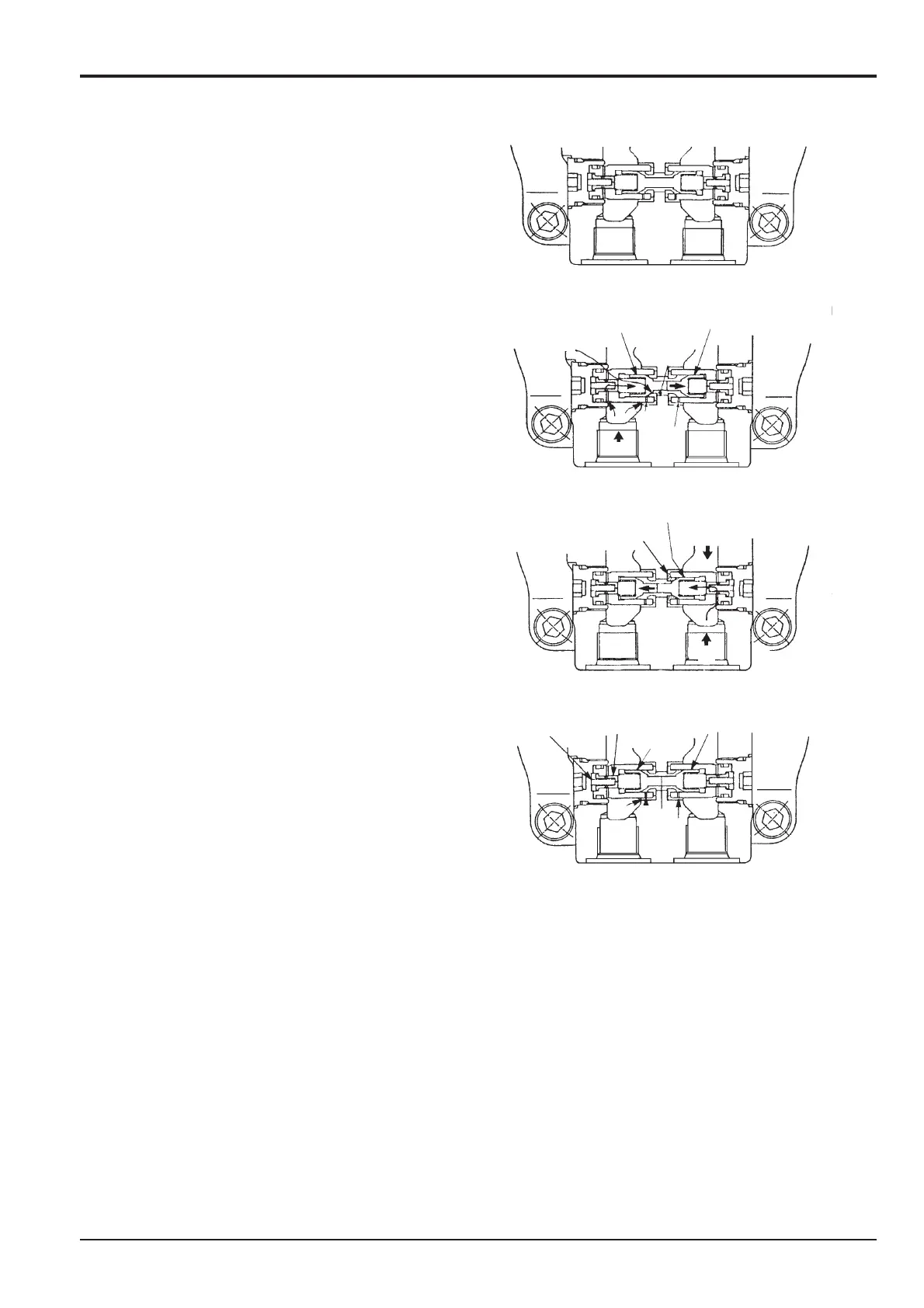

3 Swing Braking (Figure 3)

When operating the swing brake from figure 2 status,

the motor is activated by the pump, with both ports H

and J locked.

The pressure changes from high pressure to low

pressure on port H and from low pressure to high

pressure on port J. Since port J is connected with the

intermediate chamber poppet B is pushed open.

Port J, the intermediate chamber D and port H are

connected through the small hole F and the small hole E,

a small amount of oil flows out from port J to port H,

eventually the poppet C will seal on seat K and the oil

flow will be cut.

4 Swing over-run (Figure 4)

After stopping swing, the motor returns to the opposite

direction by the remaining pressure from Port J. There is

probably high pressure in port H. Since port H is

connected with the intermediate chamber D, and port J

(connected through the small hole F and the small hole

E), a little oil flows out from port J to port H.

Because there is no close of pressure between port H

and port J, the back shaking is reduced.

The oil from the spring chamber on the back section of

the poppet B, and poppet C flows out through poppet N

and spring M via the control valve.

298480

Figure 1

Figure 2

Figure 3

Figure 4

A

B

D

C

G

E

B

J

H

C

L

K

L

J

H

M

N

C

B

D

P

E

HJ

F

Loading...

Loading...