7 - 3

Section 3 Routine Maintenance

9803/6020

Section 3

7 - 3

Issue 1

Checking the Track Shoes

1 Prepare the Machine

Position the machine on level ground and switch off

the engine.

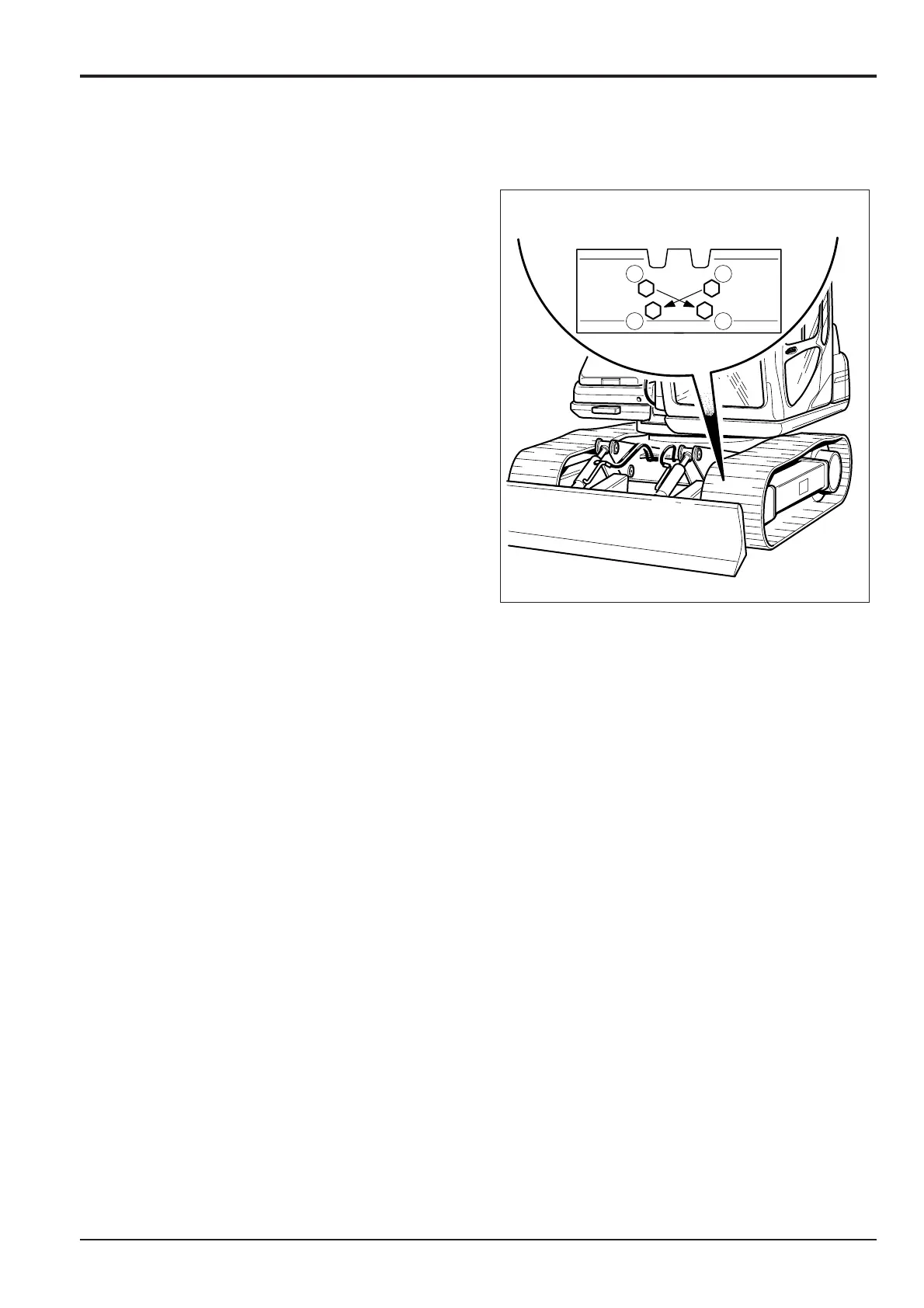

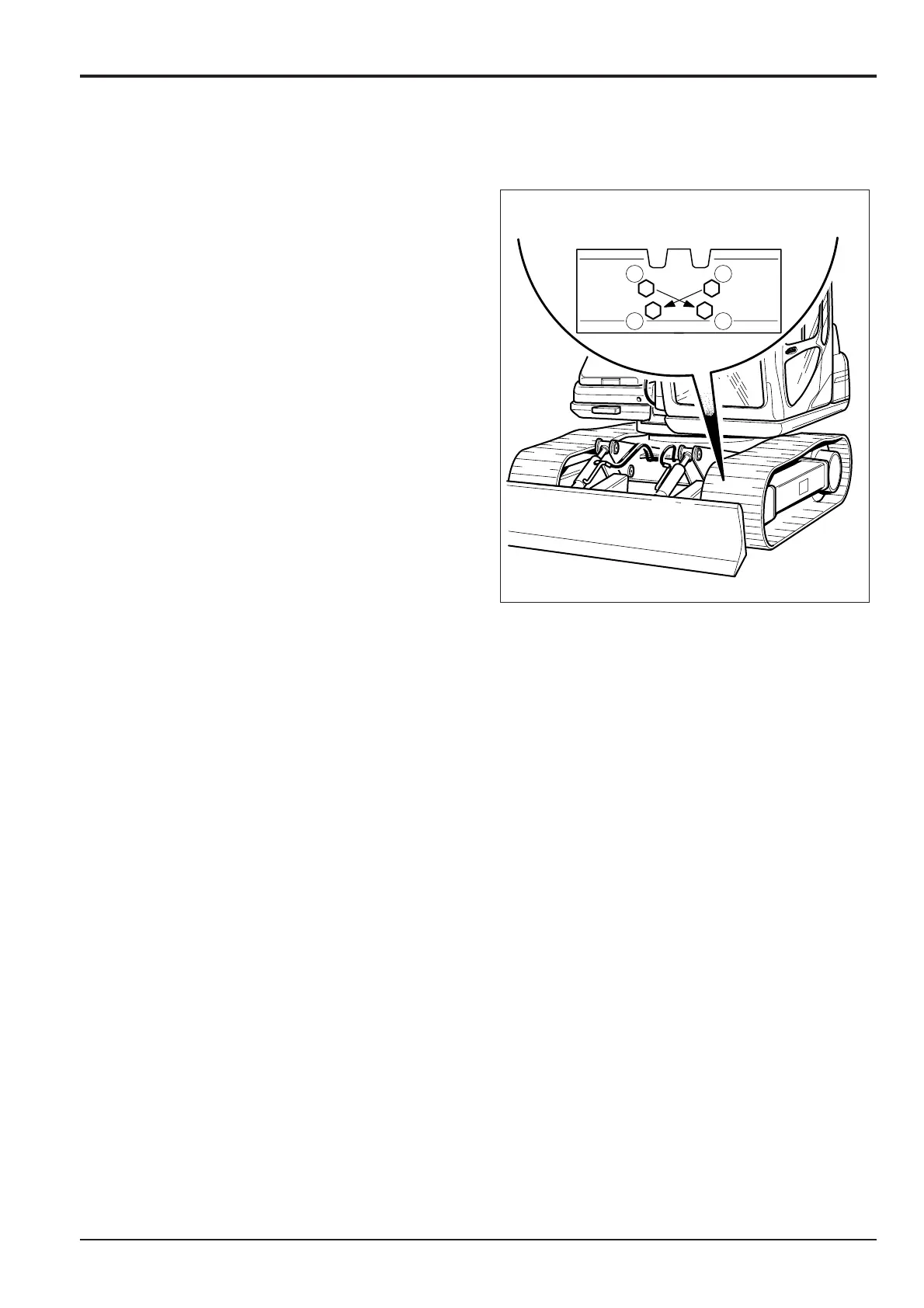

2 Inspect the Track Shoes

Check the shoes for wear and for loose mounting

bolts.

3 Carry out Repairs or Maintenance

a Replace any damaged or broken shoes.

b Tighten or re-tighten the shoe-mounting bolts in

the sequence shown at A to a torque of 197 - 236

Nm (145 - 174 lbf ft).

Checking the Rollers and Idler Wheels

for Oil Leaks

1 Prepare the Machine

See Clean the Tracks, steps 1 to 3.

Block the undercarriage.

2 Look for Oil Leaks

Check the top and bottom rollers and the idler wheels

for oil leaks.

! CAUTION

Do not run the machine if you discover oil leaks in the

top or bottom rollers or idler wheels. Failure to rectify

such leaks could cause damage to the machine.

8-3-4-6

3 Lower the Track

Remove the blocks from beneath the undercarriege.

See Clean the Tracks, step 5.

4 Repeat for the Opposite Track

Swing the boom to the other side and repeat steps 1

to 3 above.

Loading...

Loading...