25

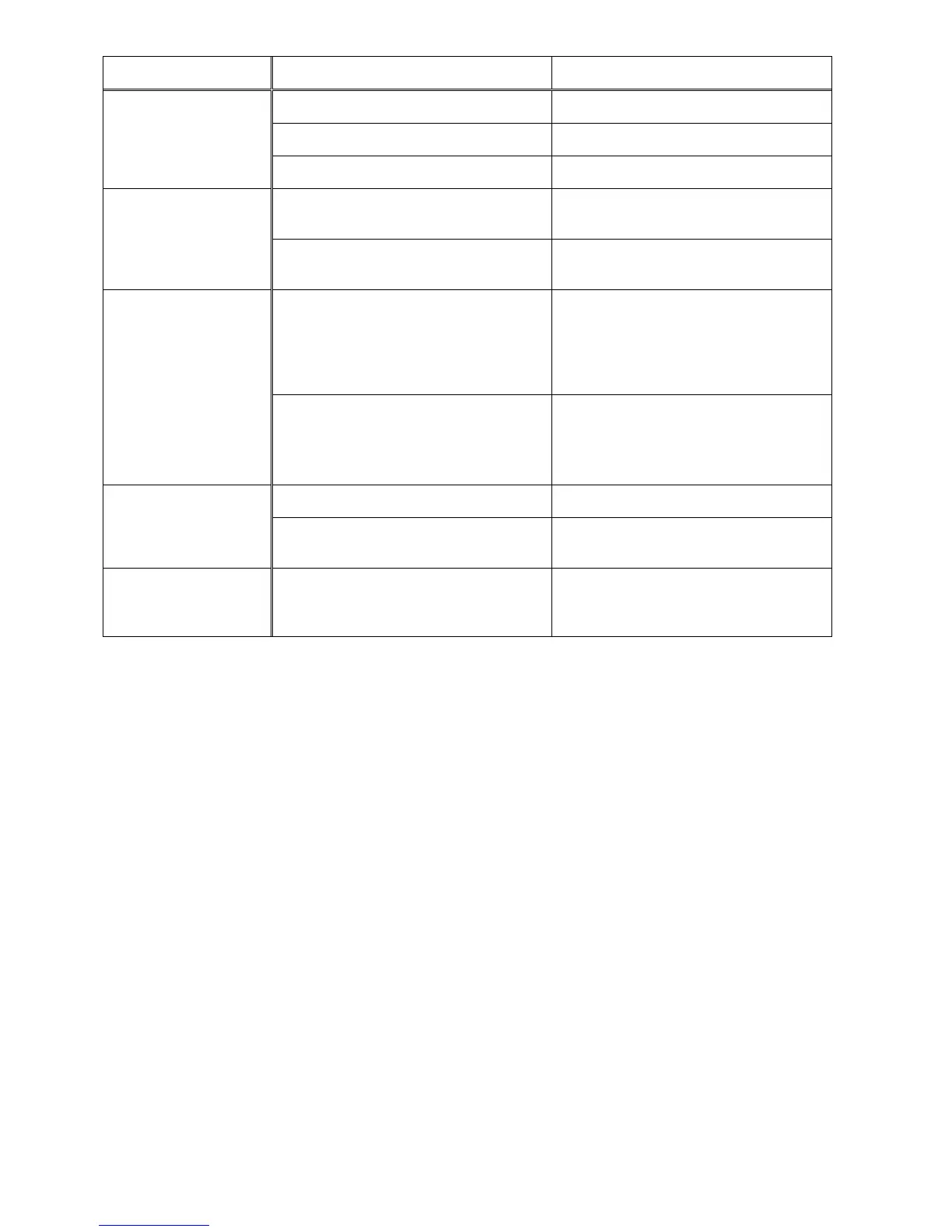

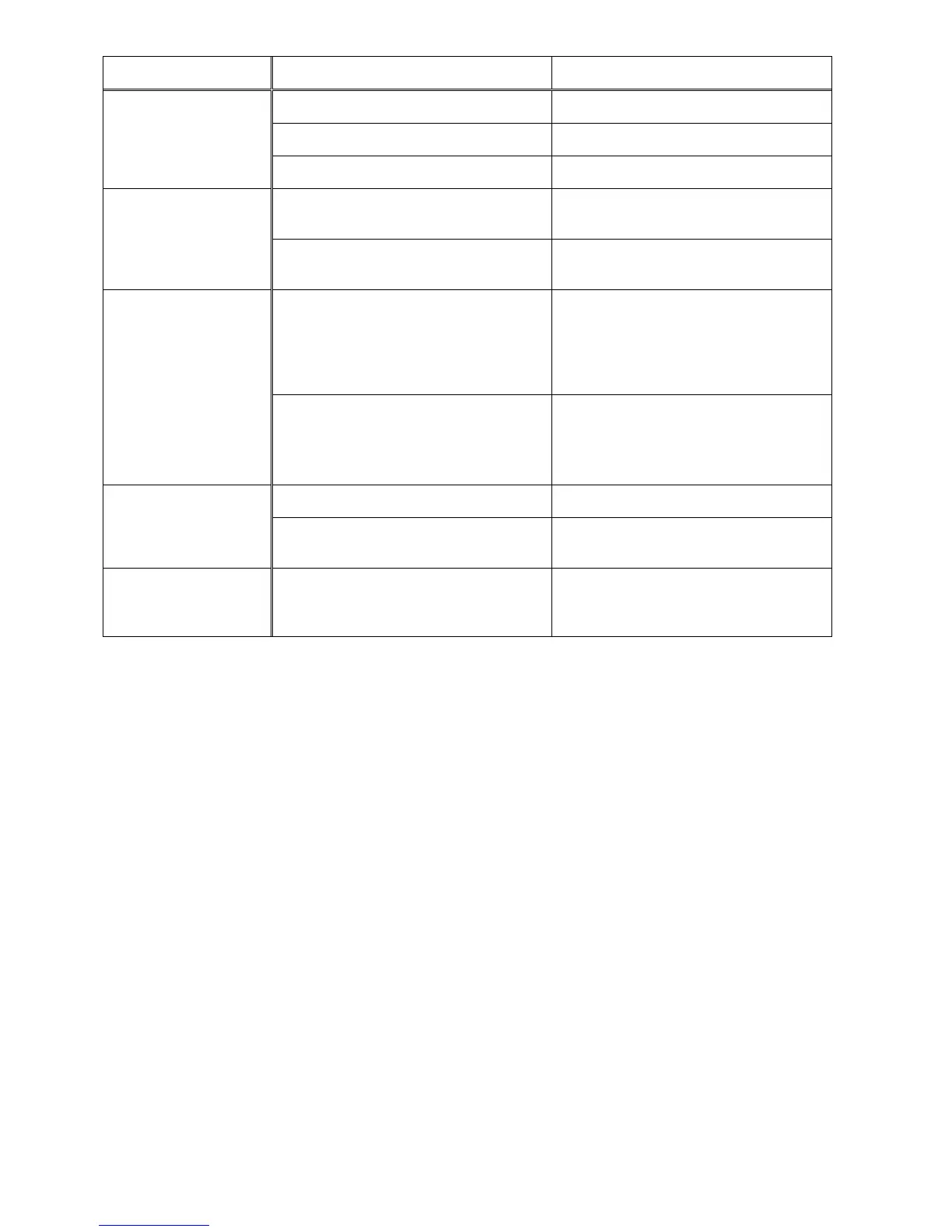

Trouble Probable Cause Remedy

Board slips on

conveyor belt.

Tension rollers too high. Lower tension rollers (see page 19).

Excessive feed rate. Reduce feed rate.

Dirty or worn conveyor belt. Replace conveyor belt.

Sander motor slows

or stalls.

Improper conveyor belt tension.

Adjust belt tension. If necessary,

reduce depth of cut and/or feed rate.

Excessive depth of cut and/or

excessive feed rate.

Reduce depth of cut or feed rate.

Ripples in sanded

surface.

A. Non-uniformly

spaced ripples.

B. Uniformly spaced

ripples.

A. Uneven feed rate.

Conveyor belt slipping (see above)

Board slips on conveyor belt (see

above).

Conveyor motor stalls (see above).

B. Conveyor bed flexing or vibration.

Reduce depth of cut and/or feed rate.

Check for loose bolts, loose shaft

coupling set screws, or out-of-balance

drum.

Wood is gouged.

Stock slipping on conveyor. Correct depth of cut or roller tension.

Work piece not properly supported.

Add work supports for long work

pieces.

Table height

adjustment works

improperly.

Improper adjustment of height control.

Readjust height control. See pages

18-19.

Loading...

Loading...