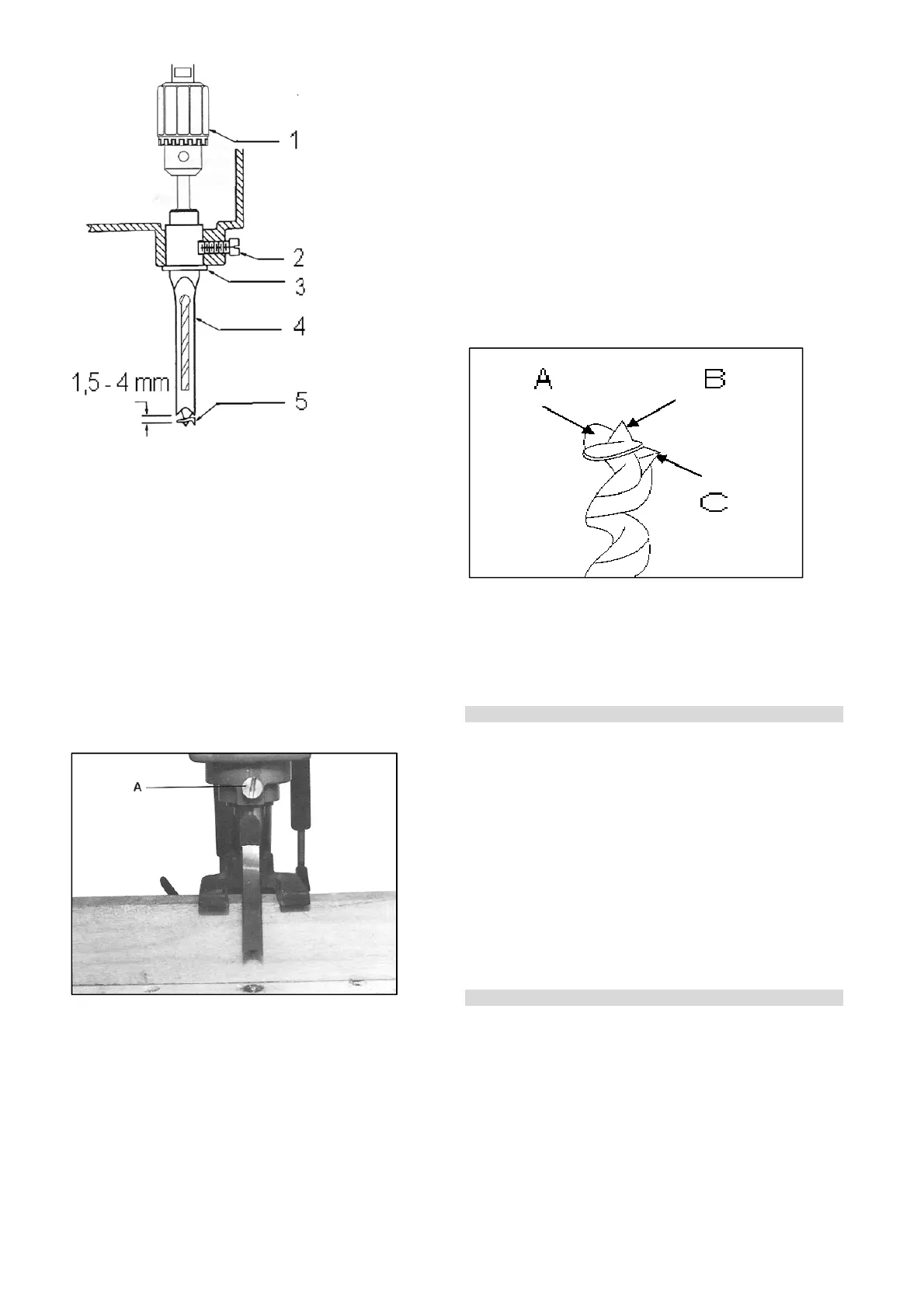

Fig 5

NOTE:

The slot in the chisel should face to the right or left side

only. The opening will allow chips to escape during

operation.

Push the chisel up as far as possible into the head. Then

lower the chisel 1,5 to 4mm, depending on the type of wood

being worked. Tighten the screw to hold the chisel in place.

Push the bit up through the chisel opening as far as it will

go. Lock the drill bit in place with the chuck key.

Loosen the screw and push the chisel up against the

bushing and tighten the screw. This should provide the

proper distance between the points of the chisel and the bit.

NOTE: The chisel should be adjusted parallel. Use the

workpiece as a gauge (Fig 6).

Fig 6

Close the chuck access doors before starting the machine.

Using bits with shorter shanks:

It will be necessary to attach the spindle extension.

Place a 10mm open spanner on the motor spindle and use

the chuck key to unscrew the chuck.

Attach the spindle extension to the chuck and reinstall.

7.2 180° Head rotation

Remove the three hex socket cap screws at the base and

rotate head and column 180°.

Doing this will enable you to outboard mortise taller items.

7.3 Sharpening chisel and bit:

The chisel and bit should be kept sharp for best

performance.

Sharpen the bit by using a small file, following the original

shape of the bit.

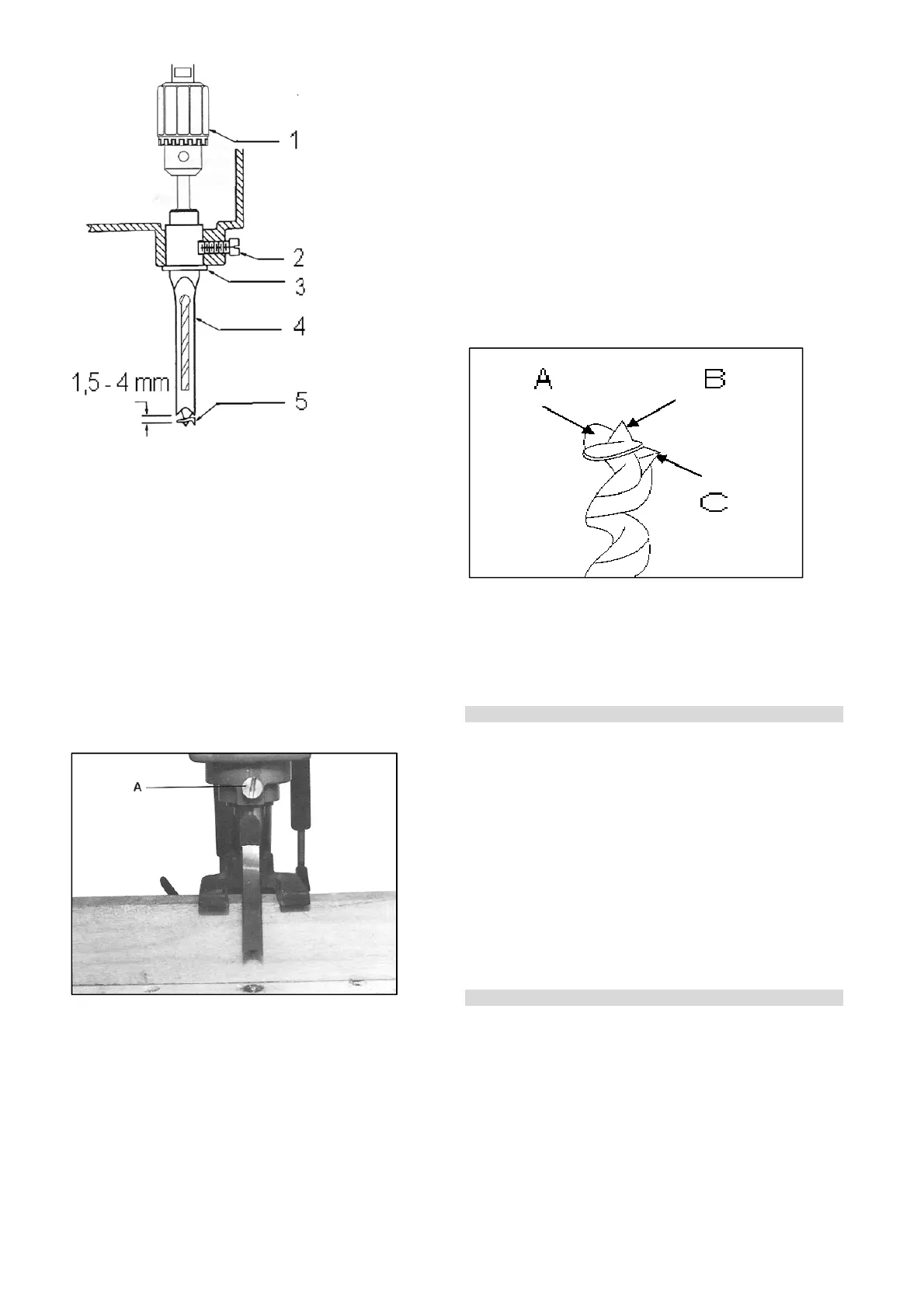

File the inside edge of the spur (A, Fig7), the sides of the

centre point (B) and the cutting edge inwards toward the

flute of the bit (C).

Fig 7

Do not file the outside edges of the spur as this will affect

the diameter of the bit.

Sharpen the chisel on the cutting edge inside only.

8. Maintenance and inspection

General notes:

Maintenance, cleaning and repair work may only be

carried out after the machine is protected against

accidental starting by pulling the mains plug.

The mortise requires only minor maintenance, such as

lubrication, routine adjustments and sharpening of chisel

and bit.

Clean the machine regularly.

Defective safety devices must be replaced immediately.

Repair and maintenance work on the electrical system may

only be carried out by a qualified electrician.

9. Trouble shooting

Motor doesn’t start

*No electricity-

check mains and fuse.

*Defective switch, motor or cord-

consult an electrician.

Chisel clogged with chips

*Clearance chisel to bit not enough-

set bit 1,5 to 4mm below chisel.

*chips cannot clear the chisel-

observe chisel slot and working order.

Loading...

Loading...