8.

WHEN

cutting mouldings, NEVER

run

the stock

· bétween the tence

and

the

moulding

cutterhead.. Refer

to

mould.ing applications

.ir\

lnstr~ction

Manual.for

details.

.9..

DIRECTION OF

FEED..

Feed work

into

à blade

or

cutter against the

direction

or' rotation of the blade

or.

cutter only.

10. NE VER use the tence as a eut-off gage

when

cross

cutting.

11.

NEVER

attempt'

to

free a

stalled

saw blàde without

first

turning the saw

OFF.

·

12. PROVIDE adequate support

to

the rear

and

sidas

of the

saw

table· for

wide

or long workpieces.

13. AVOlD KICKBACKS (work thrown back

tow.ard

yeu)

by keeping

blade shf!rp, keeping

rip

fence p;Jrallel_

to

the saw blade, keepirig

splitter

and

antikickback

fingers

and

guard in place

and

operating, by not releasing .work

bef

ore

i't is pushed a Il the way past the saw blade,

and

by not ripping work that is twisted

or

warped

or

does not have a

straight

edge to guide along the tence.

14. AVOlD. awkward . operations

and

hand

positions

where a sudden s

1 ip cou

Id

cause y our

ha

nd

to

move

into

the

cutting

tool.

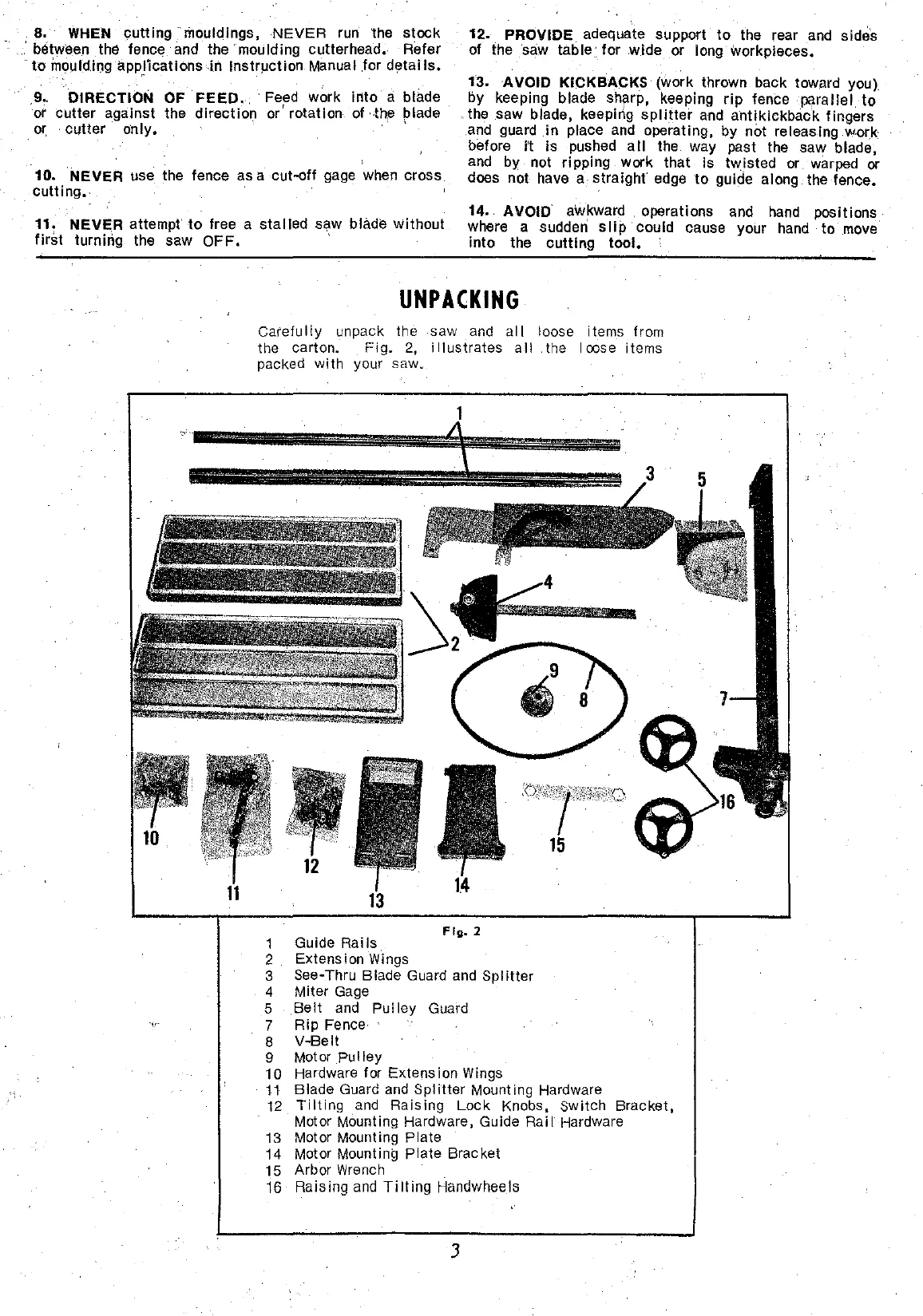

UNPACKING

Carefully unpack the saw

and

ali

loose items from

the carton.

Fig.

2,

i llustrates

ali

. the 1

oose

items

packed with your

saw.

1

t>'

,:·;;~

?Rfiii"O

,.,~t"

1 Guide Rails

Fig.

2

2 Extension

Wings

3 See-Thru Blade Guard

and

Splitter

4 Miter

Gage

5

Belt

and

Pulley Guard

7 Rip Fence

8

V-Belt

9 Motor Pulley

10

Hardware for Extension

Wings

15

11

Blade

Guard

and

Splitter Mounting Hardware

12

Tilting

and

Raising Lock Knobs, Switch Bracket,

Motor Mounting Hardware, Guide

Rail Hardware

13 Motor Mounting

Plate

14 Motor Mounting Plate Bracket

15 Arbor

Wrench

16

Raising

and

Tilting

Handwheels

3

Loading...

Loading...