6.4 Location

The drill press should be placed in a dry area, with

a level floor and good lighting. Provide enough

space around drill press to allow for operations and

any adjustments or servicing.

6.5 Assembly

Do not connect drill press to

power source until machine has been fully

assembled.

1.

Place the base upon a level floor. It may

be

s

ecured to the floor with lag screws (not

provided) through the two holes in the base.

Refer to Figure 1 for hole spacing.

If you do not wish permanent attachment to the

floor, the drill press can be bolted to a plyw

ood

panel whic

h will serve as an expanded base

and further stabilize the machine. Use a high

grade of plywood (not particle board) at least

3/4" thick. It should be large enough to prevent

vibration, sliding or moving of drill press during

operation. Do not use a mobile base with this

mach

ine.

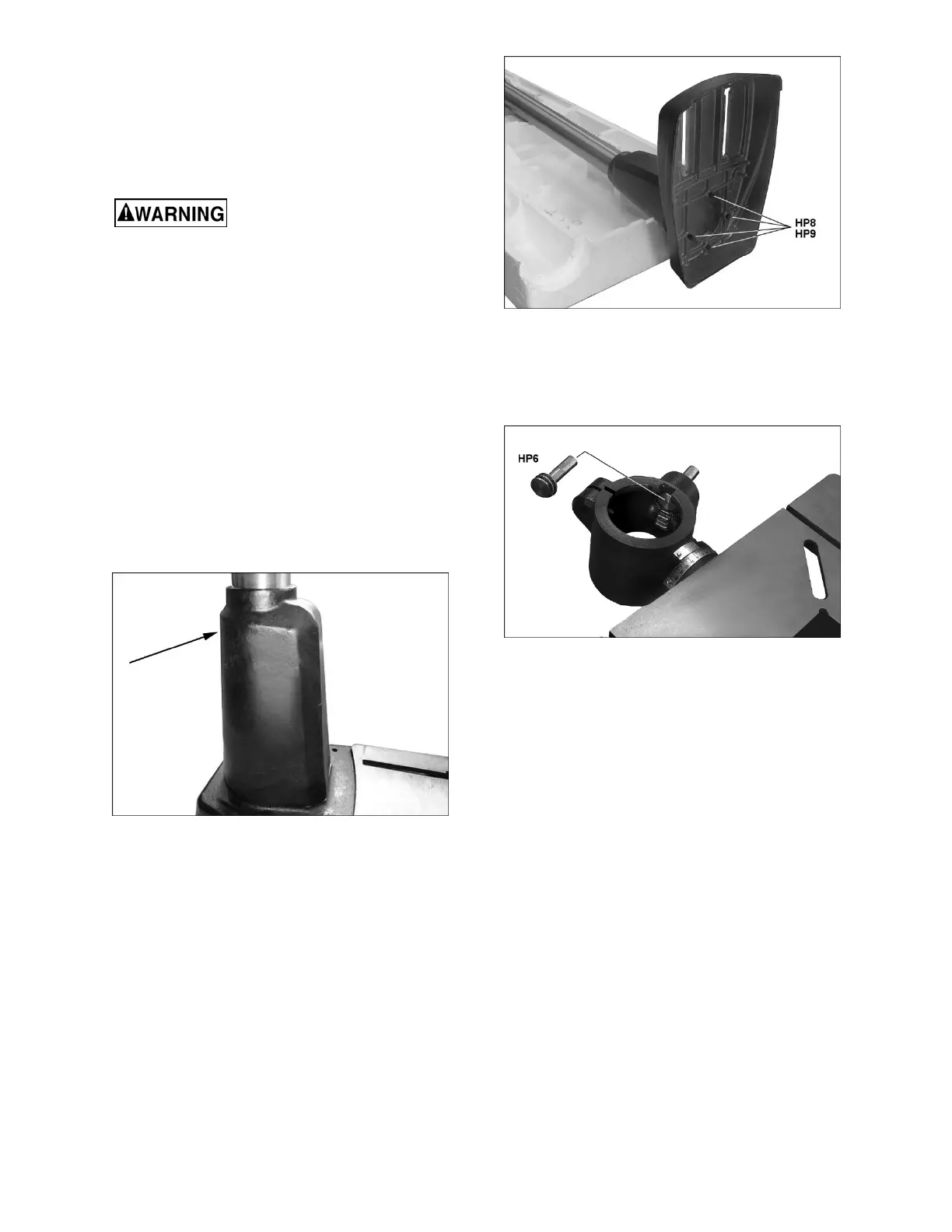

2.

Make sure the set screw (Figure 4) is

tight

agains

t the column. Tighten further if

needed,

us

ing a 5mm hex key.

Figure 4

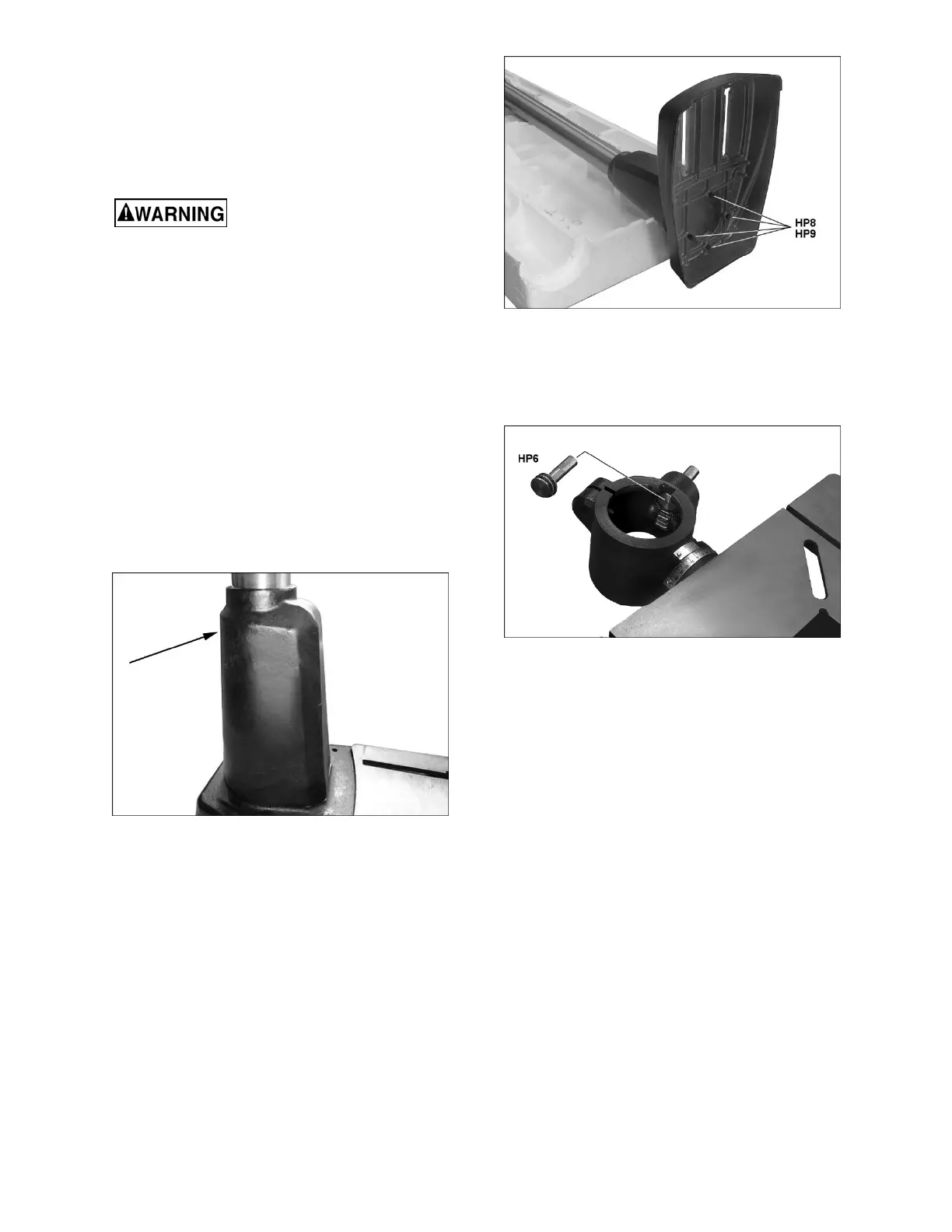

3.

Lay the column assembly down on an elevated

surface (such as the included polystyrene

packaging). Attach base to column foot with

four M8x50 socket head cap screws and f

our

8mm

flat washers (HP8/HP9, Figure 5), using a

6mm hex key. NOTE: Align base and foot so

that their edges are flush.

4. Tighten

screws firmly

.

Figure 5

5.

Set column assembly upright

.

6.

Insert the worm shaft (HP6, Figure 6) through

the hole in the table bracket as far as it will go,

meshing the worm with the teeth on the gear.

Figure 6

7.

Position rack (F, Figure 7) into the slot in table

bracket. The longer flat portion of the rack

should be at the top, the short flat portion at the

bottom. Mesh the rack teeth with the worm gea

r

in the table brac

ket.

8.

With the aid of a second person, hold the rack

in the slot, while setting the table bracket ov

er

the top of

the column. Then slide table bracket

and rack together down the column

until the

lower end of

the rack rests in the lip of

the

holder, as

s

hown in Figure 7.

Loading...

Loading...