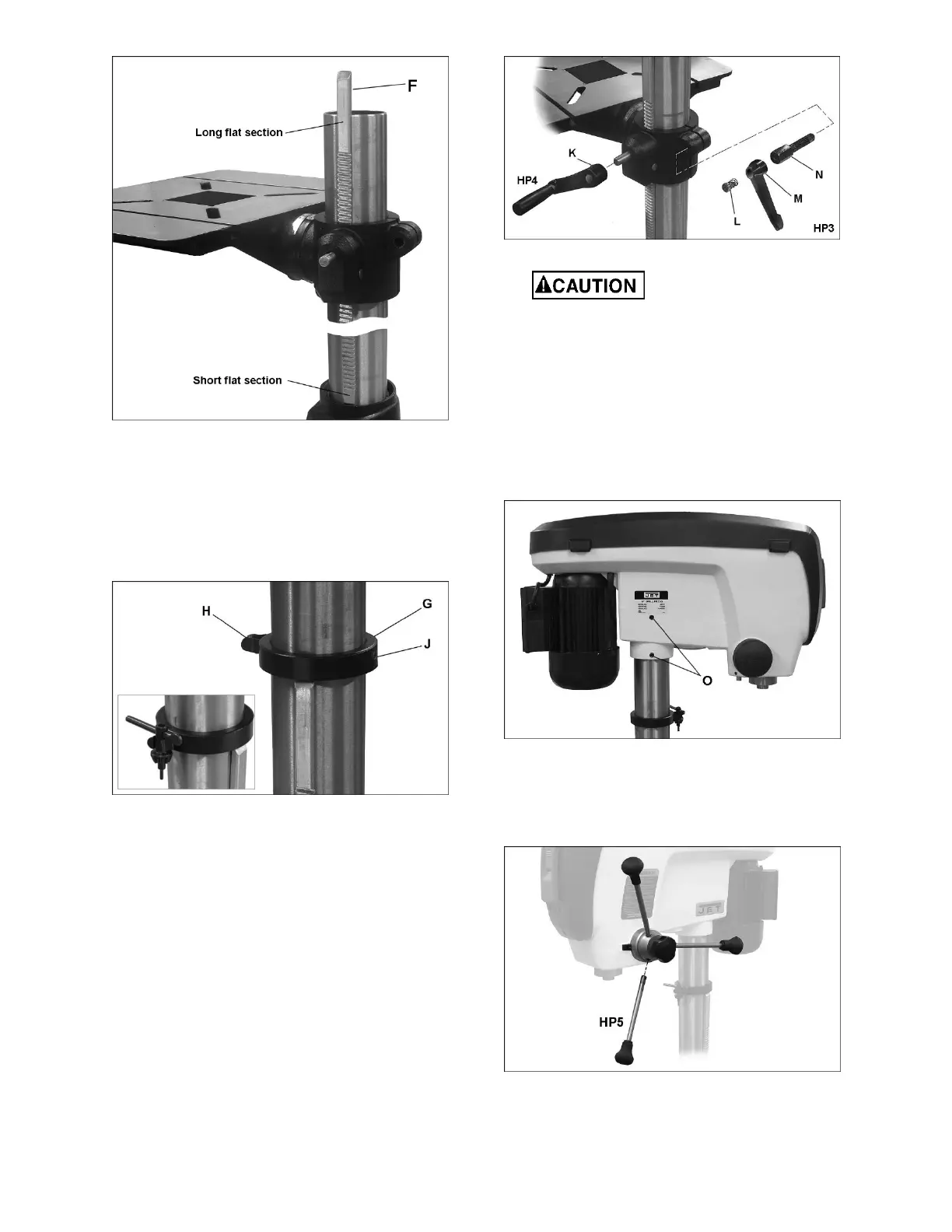

Figure 7

9.

Place stop collar (G, Figure 8) onto column

and

s

lide it down over top end of rack. Or

ient the

s

top collar so that chuck key holder (H) is

in

des

ired position around the column

.

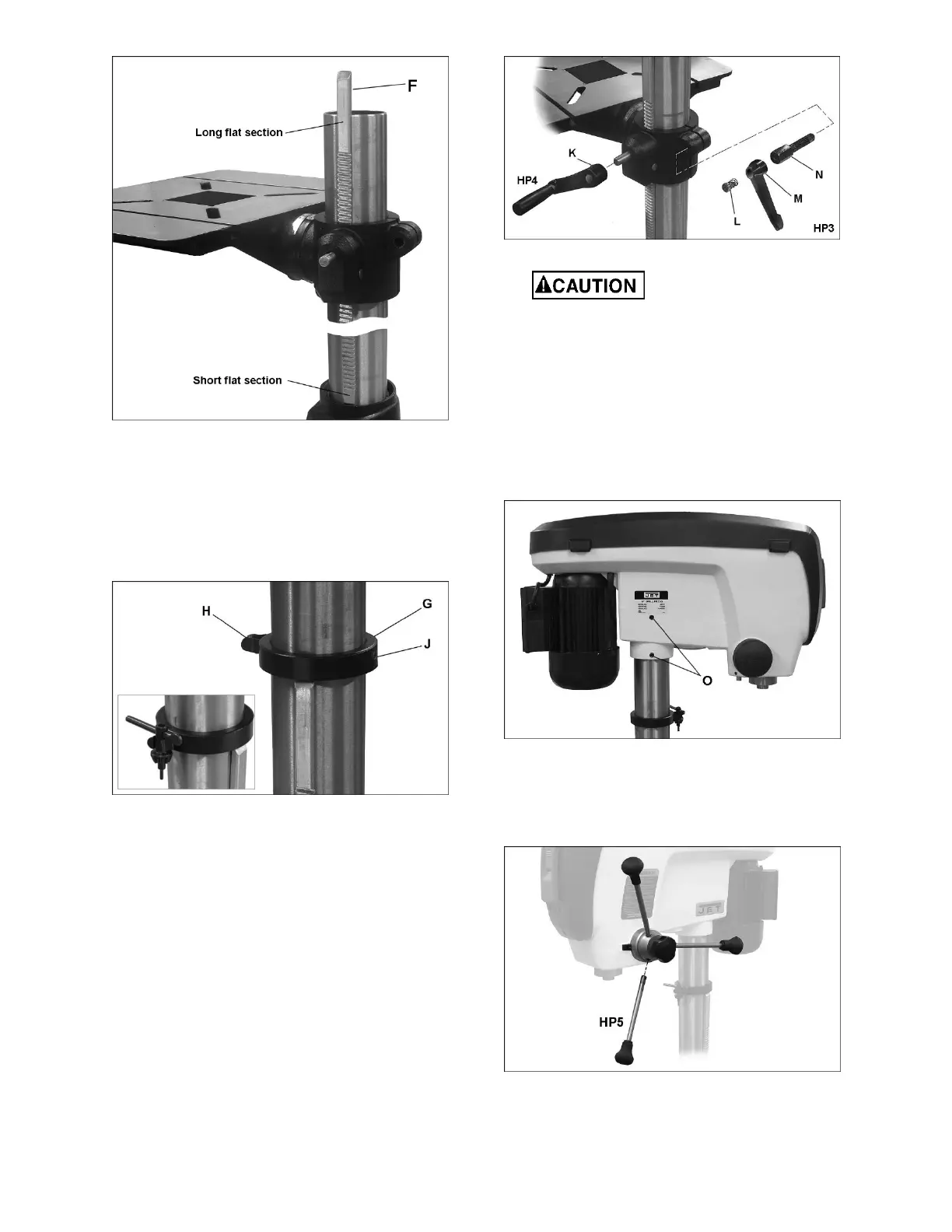

10.

Tighten set screw (J) with a 4mm hex key.

11.

Push chuck key into holder (ins

et, Figure 8)

Figure 8

12.

Slide table elevating handl

e (HP4, Figure 9)

onto protruding s

haft of worm. Make sure the

set screw in the handle aligns with the flat on

the worm shaft.

13.

Tighten set screw (K) in table elevating handle

with 4mm hex key.

14.

Mount column locking handle (HP3, Figure 9) to

rear of table bracket. The quickest way to install

this is to remove the handle by unscrewing the

screw with its spring (L). Insert the bolt (N) in

to

the table brac

ket hole, then reinstall handle (M

),

s

pring and scr

ew (L).

Note: The loc

king handle (HP3) is adjus

table.

To repos

ition, pull out on the handle and rotate

it, then release it, making sure it reseats itself

on the bolt head.

Figure 9

The head assembly is

heavy! To avoid injury and/or damage to

equipment, lift the head onto the column

only with additional assistance!

15.

With the aid of a second person, carefully lift the

head assembly and place it onto the column

.

Slide head down as

far as it will go. Rotate head

assembly until the sides of the belt cover are

parallel with the sides of the base.

16. Tighten the two set screws (O, Figure 10)

with

a 5mm

hex key until they are s

nug.

Figure 10

17.

Install three downfeed handles

(HP5, Figure 11)

into hub by

screwing them in completely. A flat

is provided on each handle for a 9mm wrench

or pliers to help tighten if nee

ded.

Figure 11

18.

Thoroughly clean spindle, arbor and chuck

(Figure 12) with a soft rag and solvent, such as

mineral spirits.

Loading...

Loading...