20

SPECIFICA TIONS

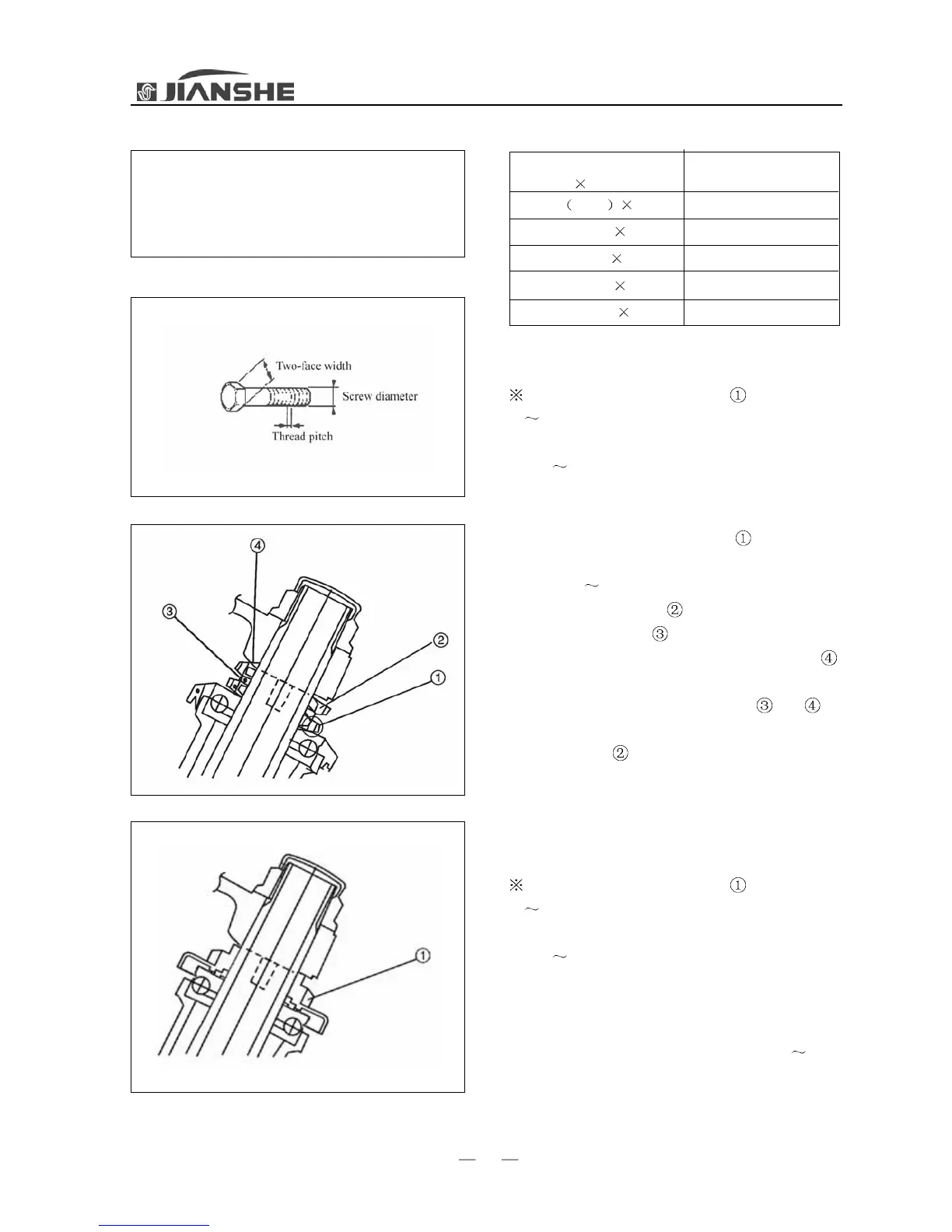

For general locking torque (except appointed locking

torque), locking torque force is determined by thread

diameter (two-face width) and thread pitch when fas-

tening a screw and a screw cap.

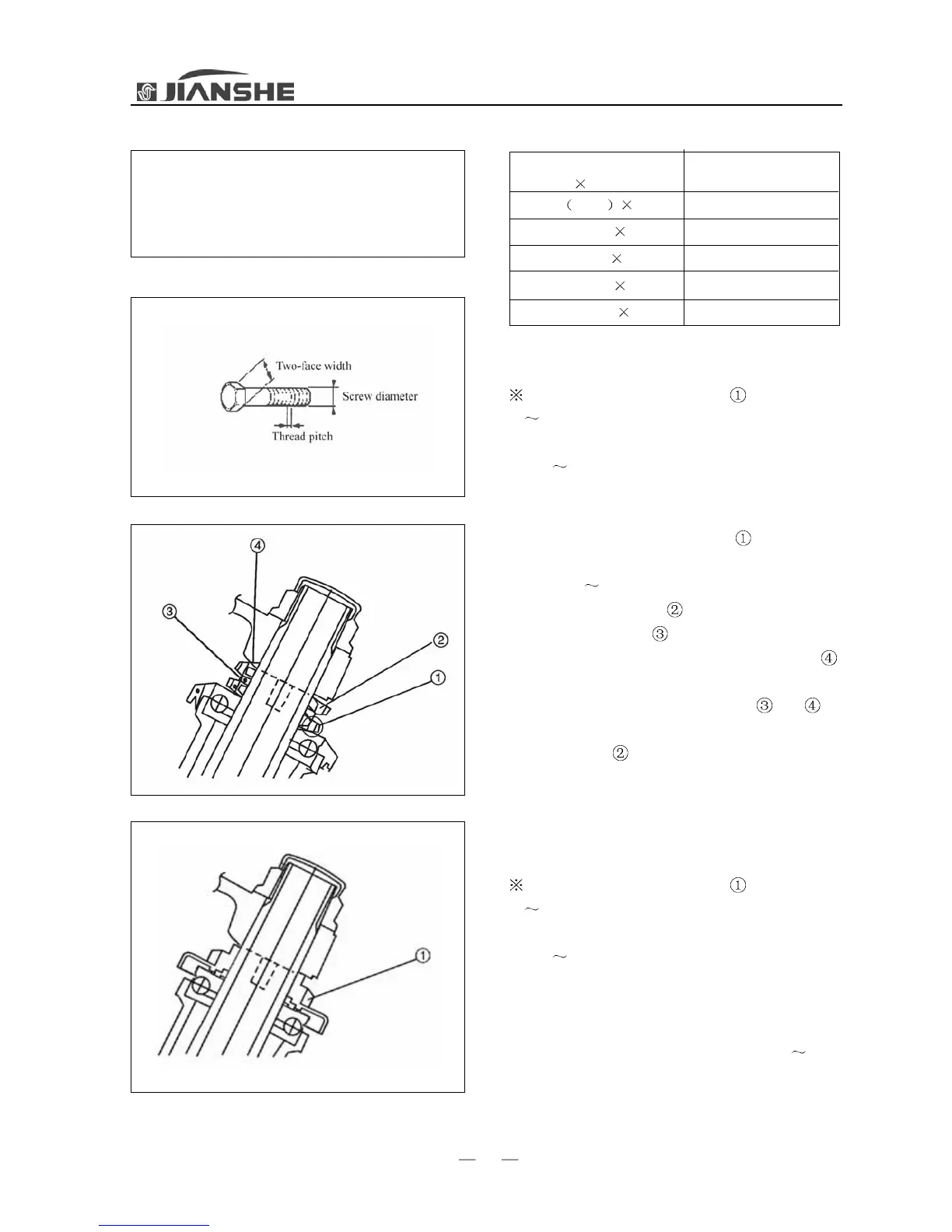

Tightening order of steering system (dual

toroidal nut)

1. First, the nut (serial number ) is fastened to

30

35N.m.

2. Then, the direction handle is turned from left to

right 2

3 times. Clamping stagnation must not be

occurred and the ball race is not flexible while the

direction handle is turned.

3. After that, the nut (serial number

) is unscrewed

one-quarter turn, and then fastened. Its fastening

torque is 20

24 N.m.

4. The nut (serial number

) is turned to press against

the nut (serial number

).

5. Then a special gasket of the nut (serial number

)

is assembled, a retaining pawl should be jammed in

the furrows of the nuts (serial number

and ) in

the meantime. If the furrows are not aligned, the nut

(serial number

) should be turned to guarantee

alignment.

Tightening order of steering system (securing

nut with dustproof)

1. First, the nut (serial number ) is fastened to

30

35N.m.

2. Then, the direction handle is turned from left to

right 2

3 times. Clamping stagnation must not be

occurred and the ball race is not flexible while the

direction handle is turned.

3. After that, the nut is unscrewed one-quarter turn,

and then fastened. Its fastening torque is 20

24 N.

Screw diameter ( two-face

width)

Thread pitch

Lock

M5 8mm 0.8

M6(10mm) 1.0

M8(12mm) 1.25

M10(14mm) 1.25

M12(17mm) 1.5

3-4N.m(0.3-0.4kg.m)

5-8N.m(0.5-0.8kg.m)

12-19N.m(1.2-1.9kg.m)

24-39N.m(2.4-3.9kg.m)

45-72N.m(4.5-7.2kg.m)

Loading...

Loading...