RWH ROTARY SCREW COMPRESSOR UNITS

OPERATION

070.620-IOM (DEC 12)

Page 17

FULL TIME PUMP SYSTEM

The full time pump system provides all oil ow requirements

for the compressor, including control oil pressure, as well as

lubrication and cooling oil ow. The pump runs continuously.

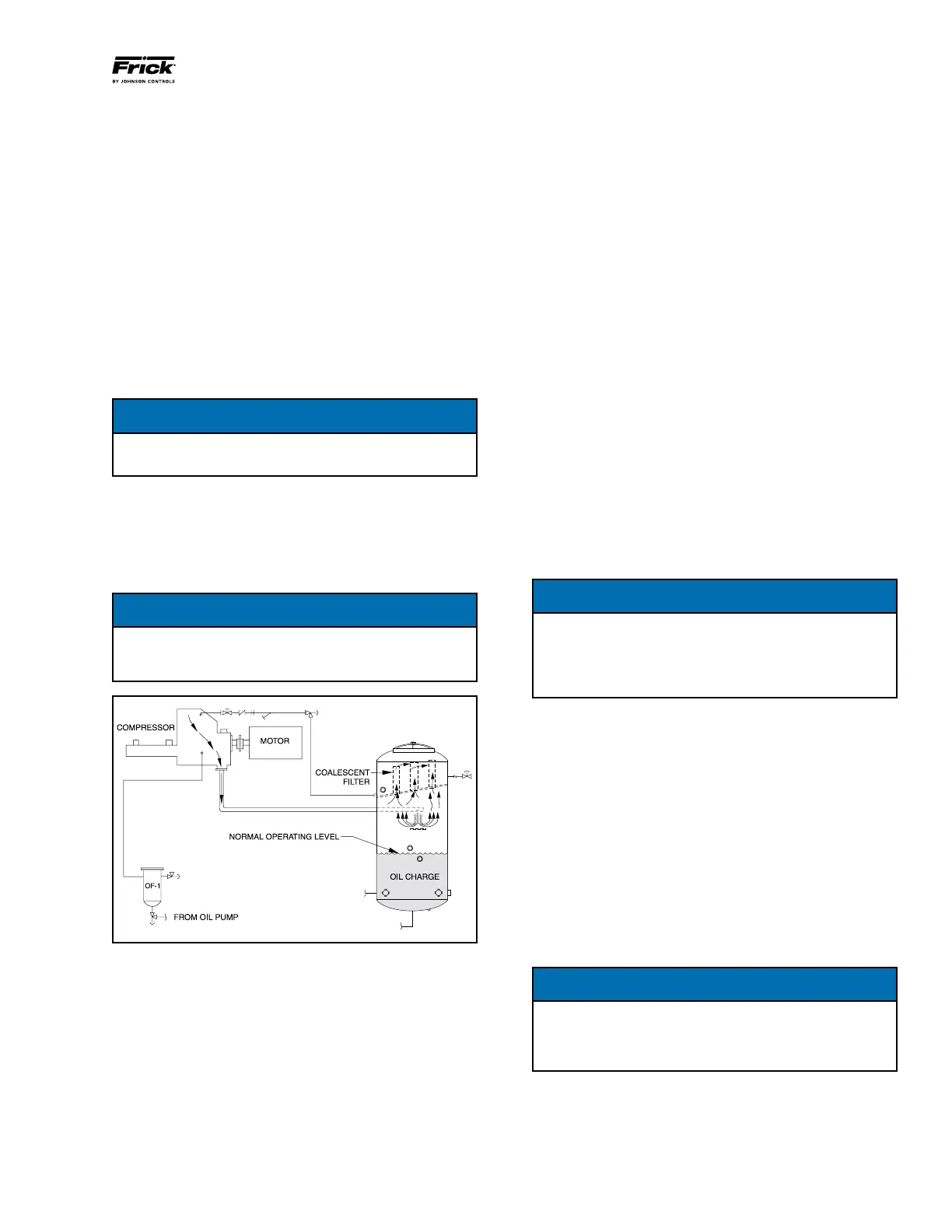

COMPRESSOR OIL SEPARATION SYSTEM

The RWH is an oil ooded screw compressor. Most of the oil

discharged by the compressor separates from the gas ow

in the oil charge reservoir. Some oil, however, is discharged

as a mist which does not separate readily from the gas ow

and is carried past the oil charge reser voir. One or more

coalescer lter elements then COALESCE the oil mist into

droplets which fall to the bottom of the coalescer section of

the oil separator. See Figure 21. The return of this oil to the

compressor is controlled by a throttling valve on both high

stage and booster applications.

NOTICE

Open throttling valve only enough to keep coalescer

end of separator free of oil.

The sight glass located near the bottom of the coales cer sec-

tion of the oil separator should remain empty during normal

operation. If an oil level develops and remains in the sight

glass, a problem in the oil return separation system or com-

pressor operation has developed. Refer to MAINTENANCE

for information on how to correct the prob lem.

NOTICE

The normal operating level is midway between the two

sight glasses located midway along the oil separator

shell.

Figure 21 - Oil Separation System

DISCHARGE BUTTERFLY CONTROL OIL SYSTEM

The valve can open when Compressor Start Output is

energized and immediately closes when the output is de

energized.

The Discharge Buttery Valve Solenoid output will only be

energized when the Discharge Pressure reaches the Con

densing Pressure. If the Solenoid needs to open when the

compressor starts, it can be controlled from the Compressor

Run Output.

The valve is controlled to maintain a minimum differential

pressure that will provide oil ow and keep the oil pressure

above the oil safeties. The Compressor Differential Pressure

Setpoint can be used to set a higher differential pressure

setting when necessary.

If the Lock Open Flag is set to True, after the valve opens

to 100% it will remain in this position until the compressor

is turned off. If the Lock Open Flag is set to False, the valve

will continue to modulate based on the compressor differ

ential pressure.

COMPRESSOR HYDRAULIC SYSTEM

The compressor hydraulic system moves the movable slide

valve (MSV) to load and unload the compressor. It also moves

the movable slide stop (MSS) to increase or decrease the

compressor’s volume ratio (Vi).

The hydraulic cylinder located at the inlet end of the SGC

compressor serves a dual purpose. It is separated by a xed

bulkhead into two sections. The movable slide valve (MSV)

sec tion is to the left of the bulkhead and the movable slide

stop (MSS) to the right. Both sections are considered double

acting hydraulic cylinders as oil pressure moves the pistons

in either direction.

Both sections are controlled by doubleacting, fourway

solenoid valves which are actuated when a signal from the

appropriate micropro cessor output energizes the solenoid

valve. Valves SV2, SV3, SC1, SC3, and T1 are always open.

NOTICE

The solenoid coils can be serviced or replaced without

evacuating the package. However, if the hydraulic so-

lenoid valves or manifold block needs to be serviced

or replaced, then the compressor package must be

evacuated.

SINGLE-ACTING MODE - High Stage

Close valve at SC2

Open valve at BP (bypass)

High stage compressor loading: The compressor loads when

MSV solenoid YY2 is energized and oil ows from the unload

side of the cylinder out port SC1, through valve ports A and

T to compressor suction. Simultaneously, discharge pressure

loads the slide valve.

High stage compressor unloading: The compressor unloads

when MSV solenoid YY1 is energized and oil ows from the

oil manifold through valve ports P and A to cylinder port SC1

and enters the unload side of the cylinder. Simultaneously,

gas on the load side of the cylinder is vented through port

SC2 and valve BP to compressor suction.

NOTICE

To control the rate of loading and unloading, change

cycle time, proportional band, and dead band setpoints

with Quantum control. If additional control is needed,

throttle SC2 or BP.

DOUBLE-ACTING MODE - Booster

Open valve at SC2

Close valve at BP (bypass)

Loading...

Loading...