RWH ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

070.620-IOM (DEC 12)

Page 30

RECOMMENDED MAINTENANCE PROGRAM

In order to obtain maximum compressor unit perform ance

and ensure reliable operation, a regular main tenance program

should be followed.

The compressor unit should be checked daily for leaks, ab

normal vibration, noise, and proper operation. A log should

also be maintained. Initial Oil analysis and Vibration analysis

should be done at startup and continued as recommended

by the Maintenance Schedule

.

VIBRATION ANALYSIS

Periodic vibration analysis can be useful in detecting bearing

wear and other mechanical failures. If vibration analysis is

used as a part of your preventive main tenance program, take

the following guidelines into consideration.

1. Always take vibration readings from exactly the same

places and at exactly the same percentage of load.

2. Use vibration readings taken from the new unit at startup

as the base line reference.

3. Evaluate vibration readings carefully as the instru ment

range and function used can vary. Findings can be easily

misinterpreted.

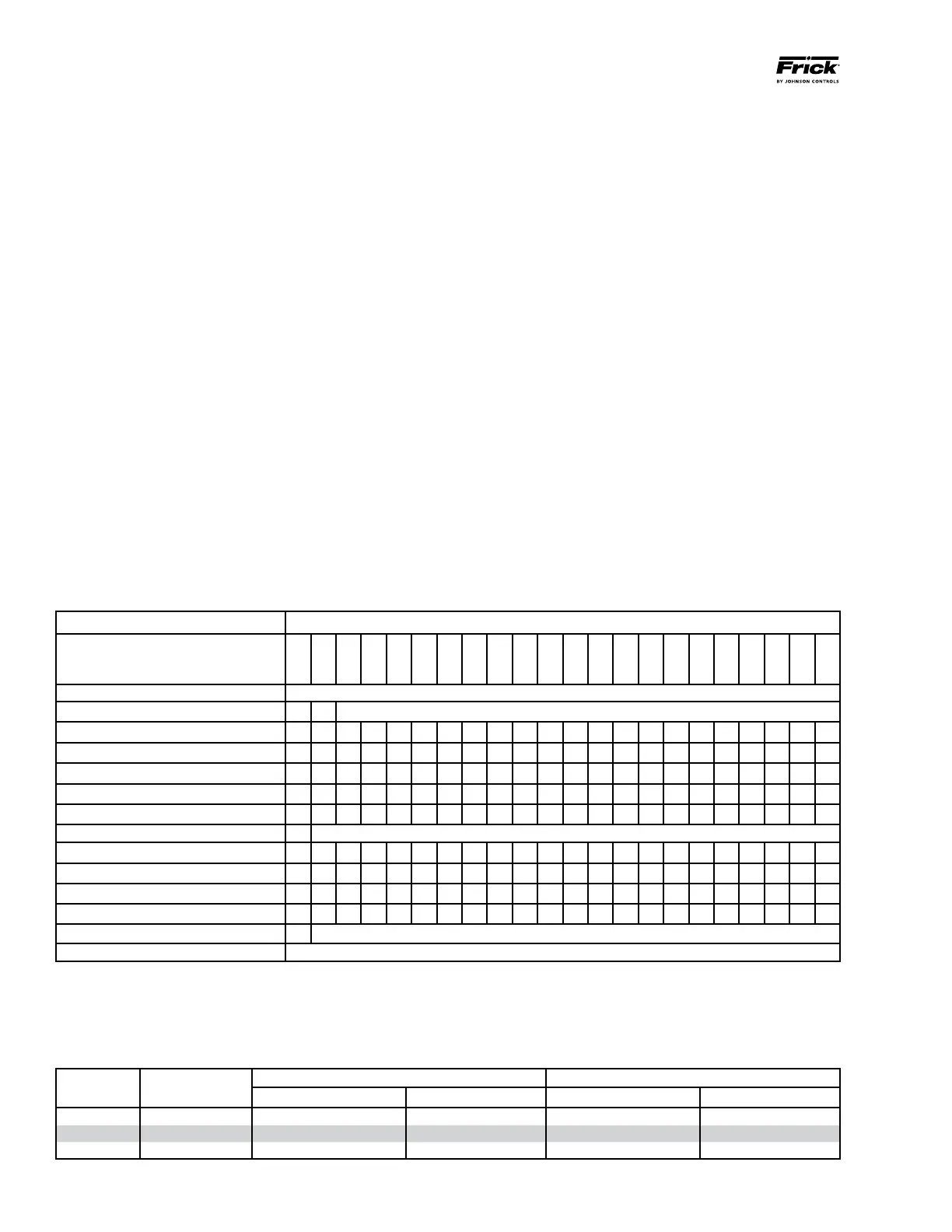

MAINTENANCE SCHEDULE

This schedule should be followed to ensure troublefree operation of the compressor unit.

PREVENTATIVE MAINTENANCE

Performing a few preventative maintenance procedures will

extend the life of your pump and reduce the cost per gallon

pumped.

1. Lubrication Grease all zerks after every 500 hours of

operation or after 60 days, whichever occurs rst. If service

is severe, grease more often. Do it gently with a hand gun.

Use #2 ball bearing grease for normal applications. For hot

or cold applications, use appropriate grease.

2. Packing Adjustment Occasional packing adjustment

may be required to keep leakage to a slight weep; if impos

sible to reduce leakage by gentle tightening, replace pack

ing or use different type. See Technical Service Manual on

particular model series for details on repacking.

3. End Clearance Adjustment After long service the run

ning clearance between the end of the rotor teeth and the

head may have increased through wear to the point where

the pump is losing capacity or pressure. Resetting end clear

ance will normally improve pump performance. See Technical

Service Manual on particular model series for procedure on

adjusting end clear ance for the pump involved.

a. Check bolts, shim packs, center inserts, keys, and all bolt torques.

b. Check and torque all terminals in the processor and starter panel per the specication posted in the enclosure.

c. Check calibration of Slide Valve, Slide Stop, pressures and temperatures. Calibration should be conducted with NIST certied devices.

d. Verify tightness of bolts on suction and discharge anges. See table below for torque requirements.

e. Vibration measurement must be carried out continuously to obtain optimum preventative control on bearings. If not continuously

controlled, then every 6 months, more frequently if levels increase.

f. Units with varible speed drives check for excess vibration and skip frequencies anytime unit operating conditions change.

FREQUENCY OR HOURS OF OPERATION (MAXIMUM)

MAINTENANCE

200

1000

5000

8000

10,000

15,000

20,000

25,000

30,000

35,000

40,000

45,000

50,000

55,000

60,000

65,000

70,000

75,000

80,000

85,000

90,000

95,000

Change Oil As Directed By Oil Analysis

Oil Analysis

n

Every 6 Months

Replace Filters

n

n

n

n

n

n

n

n

n

n

n

Clean Oil Strainers

n

n

n

n

n

n

n

n

n

n

n

Clean Liquid Strainers

n

n

n

n

n

n

n

n

n

n

n

Replace Coalescers

n

n

n

Check and Clean Suction Strainer

n

n

n

n

n

n

n

n

n

n

n

Check Coupling (a)

n

Annually Regardless of Operating Hours

Suction & Disch Flange Bolts (d)

n n n n n n n n n n n n n n n n n n n n n n

VFD Units Check Skip Freq. (f)

n n n n n n n n n n n n n n n n n n n n n n

Check Electrical Connections (b)

n n n n n n n n n n n n n n n n n n n n

Check Sensor Calibration (c)

n n n n n n n n n n n n n n n n n n n n n

Vibration Analysis (e)

n

Every 6 Months, More Frequently If Levels Increase

Replace Shaft Seal When Leak Rate Exceeds 7 8 Drops Per Minute

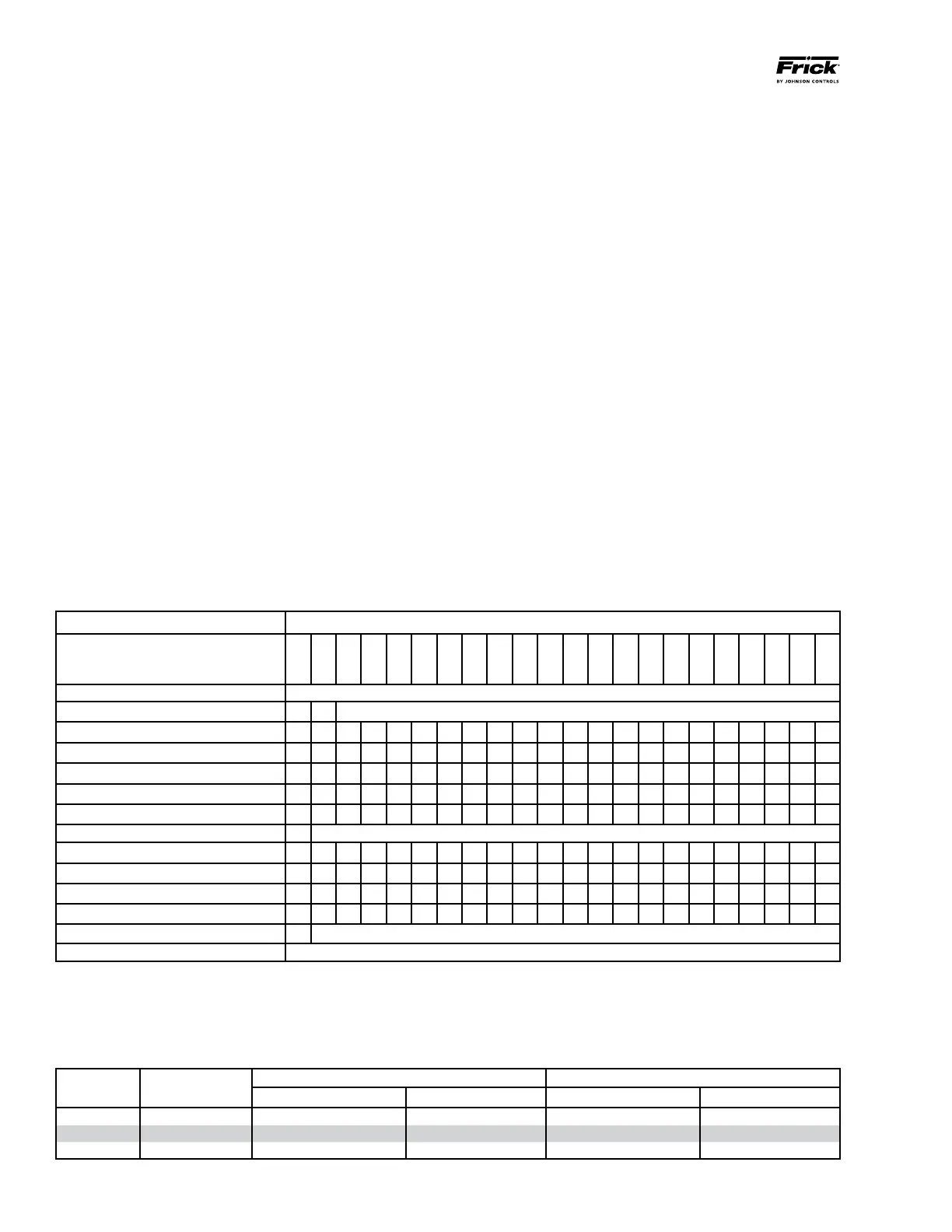

RWH

MODEL

Compressor

Model

Discharge Flange to Separator Flange Suction Flange

Bolt Size Torque* (ft-lb) Bolt Size (in.) Torque* (ft-lb)

852 TDSH 408S M24 X 3.0 240 M30 X 3.5 350

1179 TDSH 408L M24 X 3.0 240 M30 X 3.5 350

1395 TDSH 408XL M24 X 3.0 240 M30 X 3.5 350

* Based on: GasketsGarlock

®

BlueGard

®

3300; Boltsclass 8.8 or stronger hex head bolts, lightly oiled and clean

Loading...

Loading...