RWH ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

070.620-IOM (DEC 12)

Page 6

The resultant force, Fr, is given by Equation (C1):

where F

x

, F

y

, and F

z

are the force components along the x,

y, and the zaxis, respectively

The resultant moment Mr, is given by Equation (C.2):

where M

x

, M

y

, and M

z

are the force components along the

x, y, and the zaxis, respectively

Consult a licensed architect to determine the proper foun

dation requirements for any large engine or turbine drive.

When applying screw compressors at high pressures, the

customer must be prepared for package vibration and noise

higher than the values predicted for normal refrigeration duty.

Proper foundations and proper installation methods are vital;

and even then, sound attenuation or noise curtains may be

required to reduce noise to desired levels.

For more detailed information on Screw Compressor

Foundations, please request Frick

®

publication 070.210-IB.

RIGGING and HANDLING

WARNING

This screw compressor package may be top-heavy. Use

caution in rigging and handling.

The unit can be moved with rigging, using a crane and

spreader bars, by hooking into all lifting eyes on the package.

Ap propriate adjustment in the lifting point should be made to

compensate for the center of gravity. Refer to supplied engi

neering drawings to determine the package center of gravity.

CHECKING MOTOR/COMPRESS OR ROTA TION

WARNING

Make sure coupling hubs are tight-ened to the shaft

before rotatingthe motor to prevent them from ying

off and possibly causing serious injury or death.

WARNING

Injury may occur if loose clothing, etc, becomes en-

tangled on the spinning motor shaft.

COMPRESSOR ROTATION IS CLOCKWISE WHEN FACING

THE END OF THE COMPRESSOR SHAFT. Under NO condi

tions should the motor rotation be check ed with the coupling

center installed as damage to the com pressor may result.

BP SERIES COUPLING DATA TABLE

BP

DISC PACK LOCKNUT HUB CLAMPING BOLTS KEYWAY SETSCREW

SERIES

TORQUE (Lube*)

SIZE UNF

TORQUE

SIZE UNF

TORQUE

SIZE NC

SIZE FT-LB NM FT-LB NM FT-LB NM

BP 38 17 23.1 5/16-24 41 55.6 3/8-24 22 29.8 3/8-16

BP 43 40 54.2 7/16-20 41 55.6 3/8-24 22 29.8 3/8-16

BP 48 40 54.2 7/16-20 41 55.6 3/8-24 53 71.9 1/2-13

BP 53 60 81.4 1/2-20 66 89.5 7/16-20 53 71.9 1/2-13

BP 58 120 162.7 5/8-18 101 137.0 1/2-20 53 71.9 1/2-13

BP 63 120 162.7 5/8-18 101 137.0 1/2-20 186 252.2 3/4-10

Bump the motor to check for correct compressor rotation.

After verication, install disc drive spacer, as applicable.

COMPRESSOR/MOTOR COUPLING INSTALLATION

The job coupling may be one of those described below or

it may be custom specied for the application. If the latter,

refer to the engineering prints and documents as well as

coupling manufacturer instructions as applicable, based on

the actual coupling supplied.

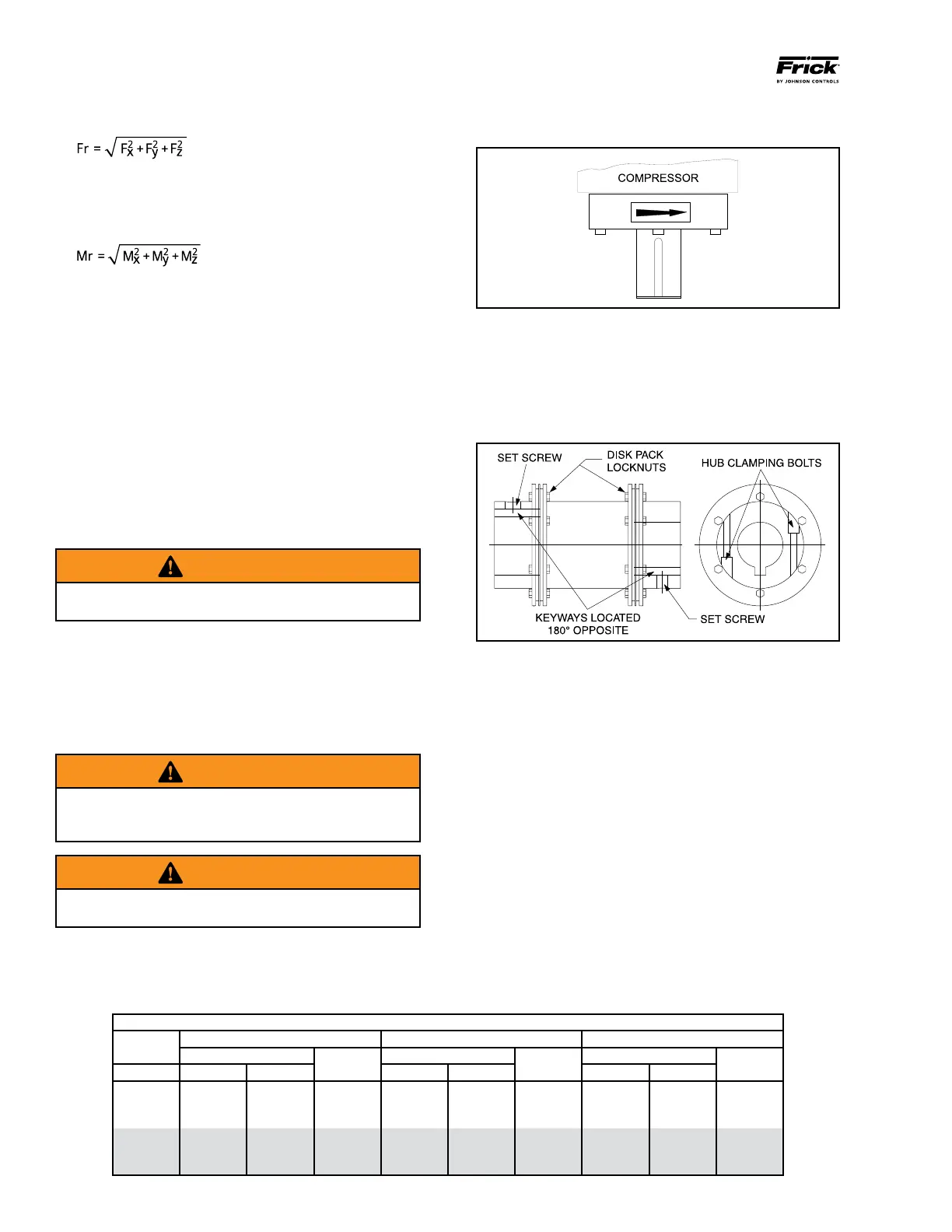

Figure 2 - BP Coupling

BP COUPLING INSTALLATION PROCEDURE

1. Install the motor and compressor coupling hubs and keys

on their respective shafts. Ensure that they can slide hori

zontally so that once the disc packs are installed, no axial

stress is transferred to the disc packs by a stuck coupling

hub. Use no lubricants.

2. Rotate both hubs so that the keys are 180° opposed (See

Figure 2). With the hubs mounted and the axial spacing set,

proceed to place the spacer between the two hub anges.

Care should be taken when handling the spacer. Be sure the

spacer is fully supported at this time. Damage to the unit

ized ex discs may result after they have been installed if

the spacer is not fully supported.

Install the unitized ex disc at this time. Start a bolt through

a bolt hole in the spacer. Put the unitized ex disc between

the hub and spacer until a bushing hole in the unitized ex

disc lines up with the bolt. Slide the bolt through the bushing

hole in the unitized ex disc. Install the locknut until it is snug.

Make sure that all bolt threads are clean and lightly oiled. Do

Loading...

Loading...