RWH ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

070.620-IOM (DEC 12)

Page 26

WARNING

Oil-entrained refrigerant may vaporize, causing a sepa-

rator pressure increase. Repeat venting and recovery

procedure, if necessary.

5. Open the drain valve(s) located on the underside of the

separator and drain the oil.

6. Drain the oil lter(s) OF1 and, if ap plicable, the oil coolers

and lter OF2.

7. Remove the old lter cartridges, then install new ones

(as previously described in the section OIL FILTER (OF-1)

MAIN SINGLE/DUAL).

8. Remove, clean, and reinstall strainer elements in the

strainers.

9. Evacuate unit to 29.88" Hg (1000 microns) vacuum.

10. Open the suction service valve and pressurize the unit

to system suction pressure. Close the suction valve and leak

test.

11. Add oil by attaching a suitable pressuretype hose to the

oil drain valve located under the separator. Using a pressure

type oil pump and recommended Frick

®

oil, open the drain

valve and ll the separator until the oil level is midway in the

top sight glass.

NOTICE

Evacuation of the oil separator will assist the ow of

oil into the unit. Also, ll slowly because oil will ll up

in the separator faster than it shows in the sight glass.

Refer to the table in the OIL CHARGE section for approximate

oil charge quantities.

12. Open the suction and discharge service valves, and also

the liquid injection and economizer service valves, if ap

plicable.

13. Close the disconnect switch for the compressor motor

starter.

14. Start the unit.

PUMP DISASSEMBLY

DANGER

BEFORE OPENING ANY VIKING PUMP LIQUID CHAM-

BER (PUMPING CHAMBER, RESERVOIR, JACKET, ETC.)

ENSURE:

1. That any pressure in the chamber has been completely

vented through suction or discharge lines or other ap-

propriate openings or connections.

2. That the driving means (motor, turbine, engine, etc.)

Has been “locked out” or made non operational so that it

cannot be started while work is being done on the pump.

FAILURE TO FOLLOW ABOVE LISTED PRECAUTIONARY

MEASURES MAY RESULT IN SERIOUS INJURY OR DEATH.

1. Mark head and casing before disassembly to ensure

proper reassembly. The idler pin, which is offset in the pump

head, must be positioned up and equal distance between

port connections to allow for proper ow of liquid through

the pump.

2. Remove the head capscrews.

3. Tilt top of head back when removing to prevent idler from

falling off idler pin.

4. Remove idler and bushing assembly. If idler bushing

needs replacing, see INSTALLATION OF CARBON GRAPHITE

BUSHINGS.

5. Insert a brass bar or piece of hardwood in the port open

ing and between rotor teeth to keep shaft from turning.

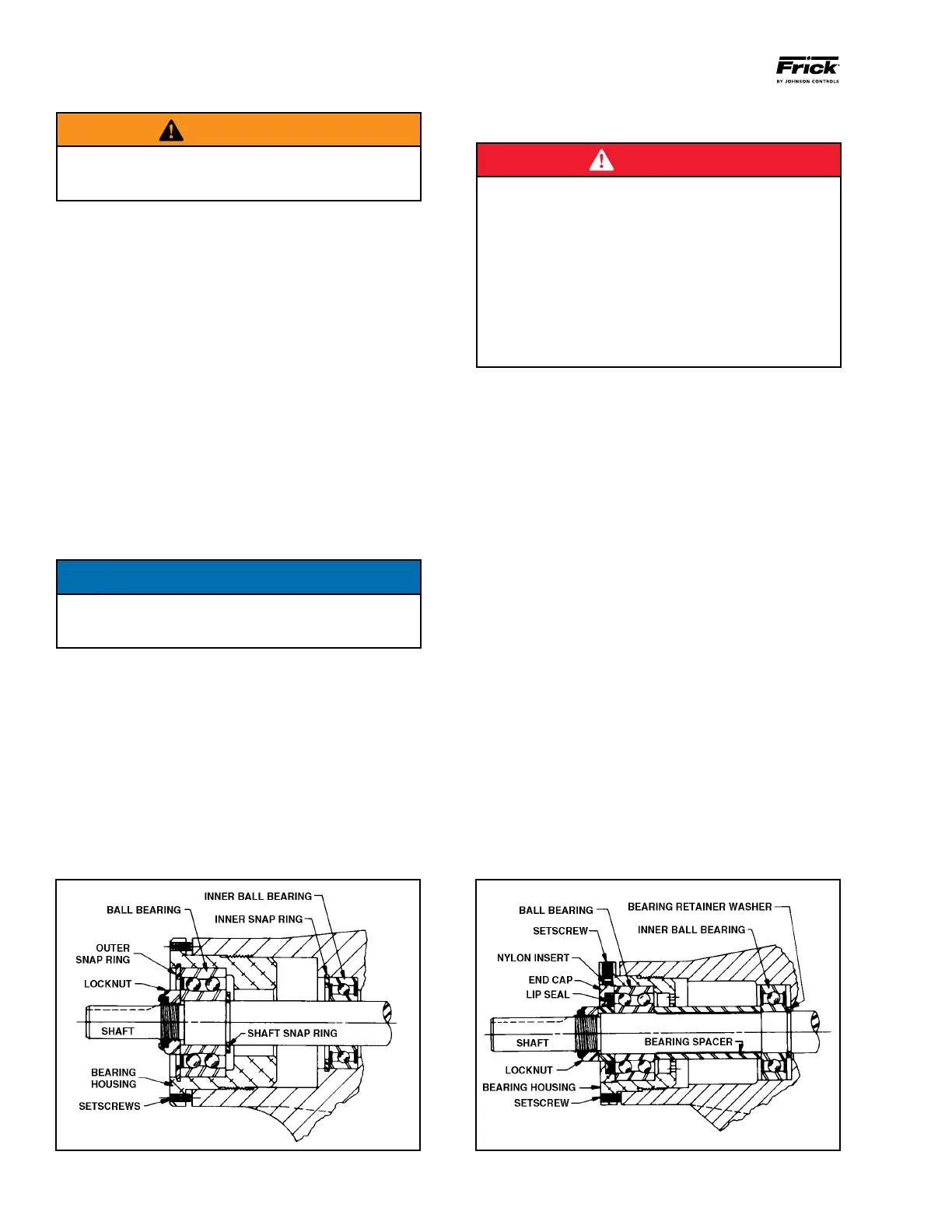

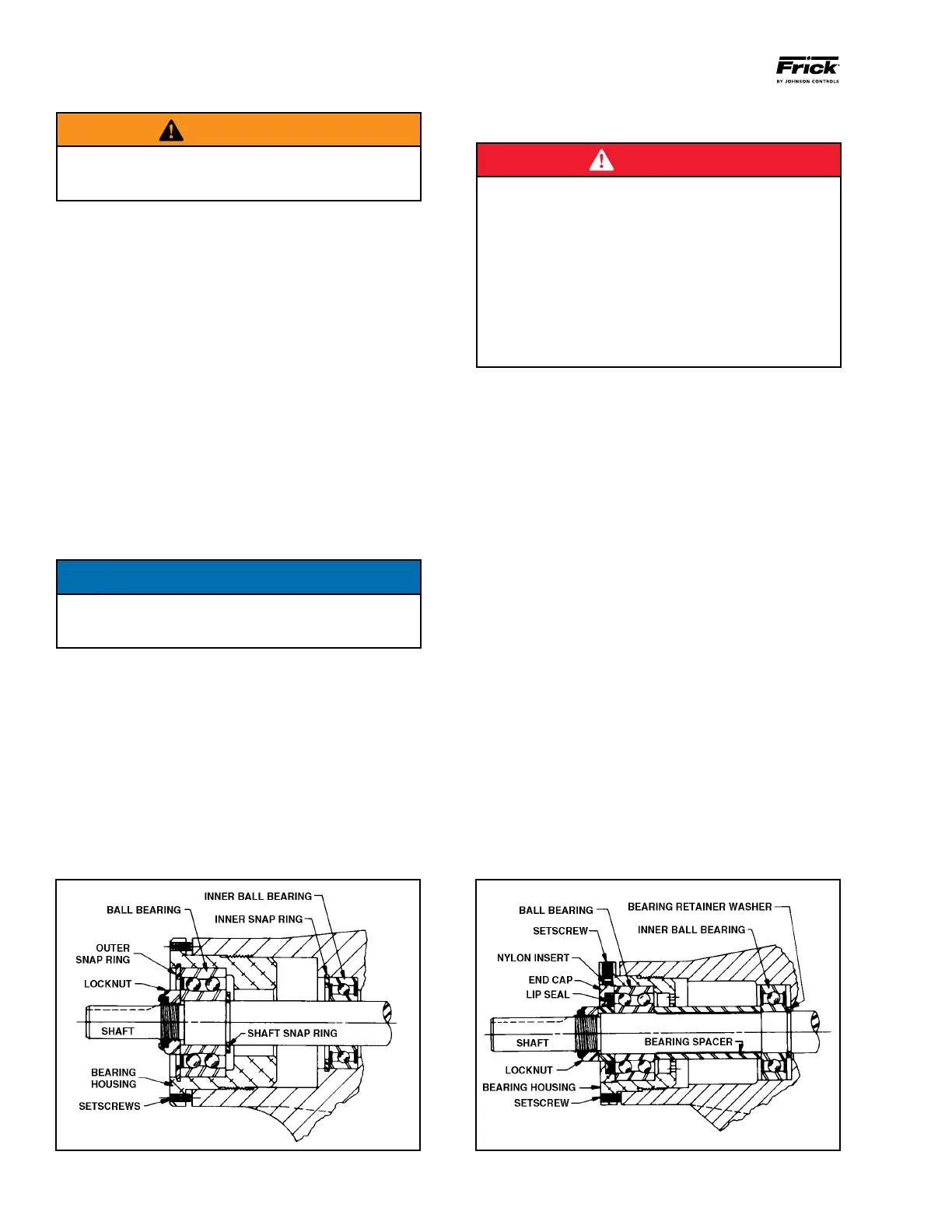

Turn the locknut counterclockwise and remove locknut. See

Figure 28 or 29.

6. Loosen two setscrews in face of bearing housing and turn

thrust bearing assembly counterclockwise and remove from

casing. See Figure 28 or 29.

7. GG, HJ, HL: Remove snap ring from shaft. See Figure 28.

AS, AK, AL: Remove bearing spacer from shaft. See Figure

29.

8. Remove brass bar or piece of hardwood from port opening.

9. The rotor and shaft can now be removed by tapping on

end of shaft with a lead hammer or, if using a regular ham

mer, use a piece of hardwood between shaft and hammer.

Figure 28 - Thrust-Bearing assembly (GG, HJ, HL) Figure 29 - Thrust-Bearing assembly (AS, AK, AL)

Loading...

Loading...