RWH ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

070.620-IOM (DEC 12)

Page 33

10. The voltage reading should be between 1.1 VDC and 1.29

VDC at standard atmospheric pressure (see Step 12).

11. Since the discharge pressure, PE3, cannot be closed off

from its sensing point (code require ments), close all trans

ducers from atmosphere and open them to their sensing

points so all transducers can equalize to separator pressure.

12. Measure the voltage of PE3 on connector P5B (terminals

WHT and BLK) on the Analog Board.

13. Measure the voltage of PE1 on connector P5A (terminals

WHT and BLK) on the Analog Board.

14. These two voltages should be within .04 VDC of one

another.

15. Test is complete.

Make a list of all deviations from normal plant operation and

normal compressor unit operation. Delete any items which

do not relate to the symptom and separately list those items

that might relate to the symptom. Use the list as a guide to

further investi gate the problem.

The second step in problem solving is to decide which items

on the list are possible causes and which items are additional

symptoms. High discharge temperature and high oil tem

perature readings on a display may both be symptoms of a

problem and not casually relat ed. High suction superheat or

a low receiver level, however, could cause both symptoms.

The third step is to identify the most likely cause and take

action to correct the problem. If the symptoms are not

relieved move to the next item on the list and repeat the

procedure until you have identied the cause of the problem.

Once the cause has been identi ed and con rmed make the

necessary correc tions.

PRESSURE TRANSDUCERS - TESTING

1. Shut down the compressor and allow pressures to equalize.

2. Isolate suction transducer PE4 from the unit and depres

surize. Ensure that the transducer has proper voltage for

excitation. Measure across the red and black wires (power

and DC common) of the transducer. Voltage should be 11.8

to 15 VDC.

NOTICE

Recover or transfer all refrigerant vapor, in accordance

with local ordinances, before opening to atmosphere.

3. Measure the voltage of PE4 on connector P6A (terminals

WHT and BLK) on the Analog Board with a digital voltmeter.

4. The voltage reading should be 1.48 VDC to 1.72 VDC at

standard atmospheric pressure (14.7 PSIA or 0 PSIG). When

checking transducers at higher elevations, an allowance in

the readings must be made by subtracting approximately 0.02

VDC per 1000 feet of elevation above sea level. Therefore,

if PE4 is measured at 5000 feet elevation under relatively

normal weather conditions, the output voltage should differ

by 0.10 VDC to read between 1.38 VDC and 1.62 VDC.

5. Isolate the oil pressure transducer PE1 from the package

and open it to atmosphere.

6. Measure the voltage of PE1 on connector P5A (terminals

WHT and BLK) on the Analog Board.

7. The voltage reading should be between 1.1 VDC and 1.29

VDC at standard atmospheric pressure. PE1, PE2, and PE3

all have a span of 500 PSI as compared to PE4 with a span

of 200 PSI. Therefore, atmospheric pressure changes have a

lesser effect which is 0.0067 VDC per 1000 feet of elevation

and 0.00067 VDC per 0.1 inch Hg barometric deviation.

8. Isolate transducer PE2 from the package and depres

surize.

NOTICE

Recover or transfer all refrigerant vapor, in accordance

with local ordinances, before opening to atmosphere.

9. Measure the voltage of PE2 on connector P5B (terminals

WHT and BLK) on the Analog Board.

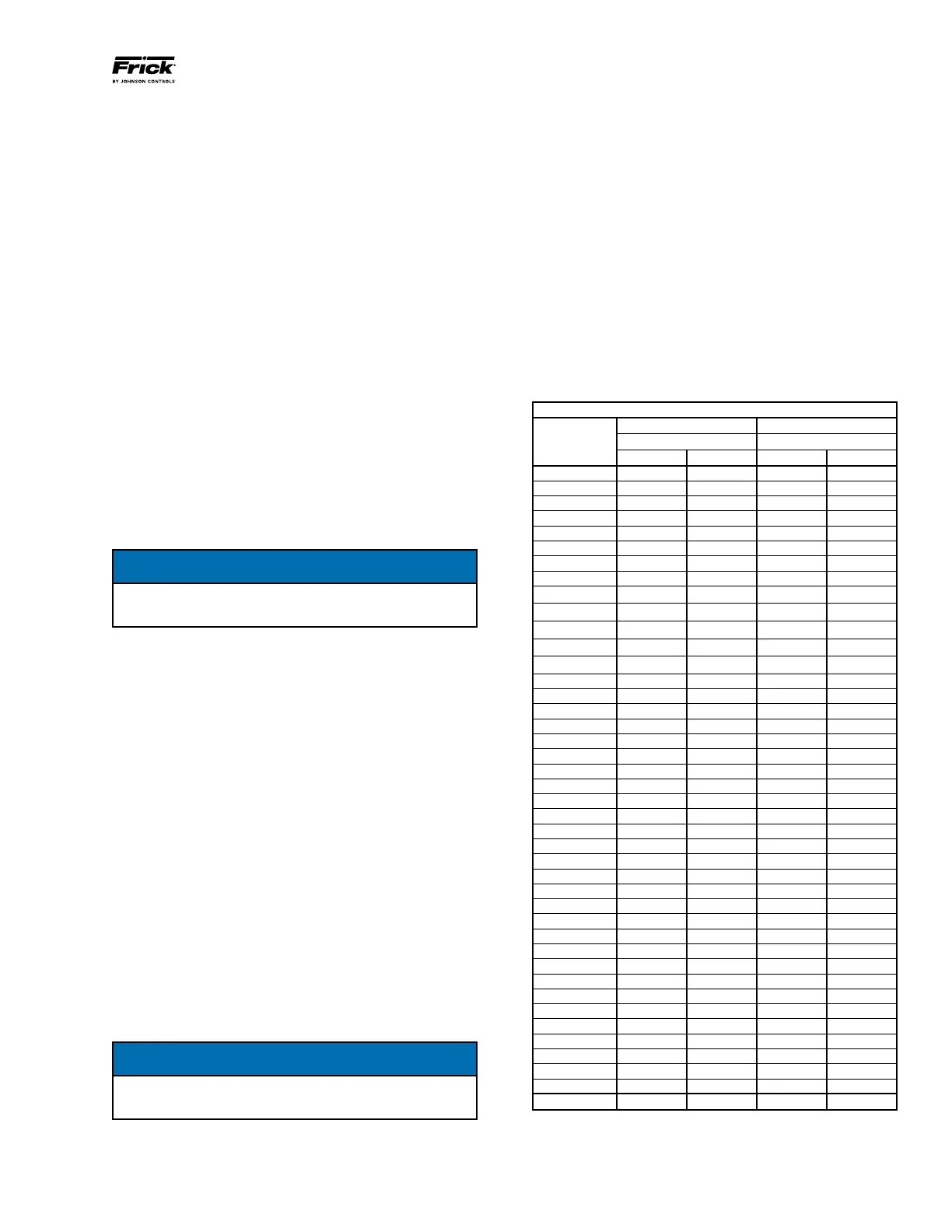

PRESSURE TRANSDUCER CONVERSION DATA

200 psi 500 psi

Sensor Range - PSIG* Range - PSIG*

Voltage low high low high

1.0 29.92" 9.57" 29.92" 4.1

1.1 29.92" 0.3 29.92" 16.6

1.2 29.92" 5.3 17.10" 29.1

1.3 19.74" 10.3 4.1 41.6

1.4 9.57" 15.3 16.6 54.1

1.5 0.3 20.3 29.1 66.6

1.6 5.3 25.3 41.6 79.1

1.7 10.3 30.3 54.1 91.6

1.8 15.3 35.3 66.6 104.1

1.9 20.3 40.3 79.1 116.6

2.0 25.3 45.3 91.6 129.1

2.1 30.3 50.3 104.1 141.6

2.2 35.3 55.3 116.6 154.1

2.3 40.3 60.3 129.1 166.6

2.4 45.3 65.3 141.6 179.1

2.5 50.3 70.3 154.1 191.6

2.6 55.3 75.3 166.6 204.1

2.7 60.3 80.3 179.1 216.6

2.8 65.3 85.3 191.6 229.1

2.9 70.3 90.3 204.1 241.6

3.0 75.3 95.3 216.6 254.1

3.1 80.3 100.3 229.1 266.6

3.2 85.3 105.3 241.6 279.1

3.3 90.3 110.3 254.1 291.6

3.4 95.3 115.3 266.6 304.1

3.5 100.3 120.3 279.1 316.6

3.6 105.3 125.3 291.6 329.1

3.7 110.3 130.3 304.1 341.6

3.8 115.3 135.3 316.6 354.1

3.9 120.3 140.3 329.1 366.6

4.0 125.3 145.3 341.6 379.1

4.1 130.3 150.3 354.1 391.6

4.2 135.3 155.3 366.6 404.1

4.3 140.3 160.3 379.1 416.6

4.4 145.3 165.3 391.6 429.1

4.5 150.3 170.3 404.1 441.6

4.6 155.3 175.3 416.6 454.1

4.7 160.3 180.3 429.1 466.6

4.8 165.3 185.3 441.6 479.1

4.9 170.3 190.3 454.1 491.6

5.0 175.3 195.3 466.6 504.1

At 0 psig 1.094 V 1.494 V 0.968 V 1.268 V

* Below 0 PSIG measured in inches of mercury.

Loading...

Loading...