349218-JIM-F-0512

Johnson Controls Unitary Products 53

Checking Gas Heat Input

1. Turn off all other gas appliances connected to the gas meter.

2. With the furnace turned on, measure the time needed for

one revolution of the hand on the smallest dial on the

meter. A typical gas meter usually has a 1/2 or a 1 cubic

foot test dial.

3. Using the number of seconds for each revolution and the

size of the test dial increment, find the cubic feet of gas

consumed per hour from the Gas Rate - Cubic Feet Per

Hour Table 24.

If the actual input is not within 5% of the furnace rating (with

allowance being made for the permissible range of the regulator

setting), replace the orifice spuds with spuds of the proper size.

NOTE: To find the Btu input, multiply the number of cubic feet

of gas consumed per hour by the Btu content of the gas

in your particular locality (contact your gas company for

this information - it varies widely from city to city.).

EXAMPLE

By actual measurement, it takes 13 seconds for the hand on the

1-cubic foot dial to make a revolution with just a 300,000 Btuh

furnace running. Read across to the column in the table above,

headed “1 Cubic Foot”, where you will see that 278 cubic feet of

gas per hour are consumed by the furnace at that rate. Multiply

278 x 1050 (the Btu rating of the gas obtained from the local

gas company). The result is 292,425 Btuh, which is close to the

300,000 Btuh rating of the furnace.

Manifold Gas Pressure Adjustment

Small adjustments to the high-fire gas flow may be made by

turning the pressure regulator adjusting screw on the automatic

gas valve.

Adjust as follows:

1. Remove the cap on the regulator. It's located next to the

push-on electrical terminals.

2. To decrease the gas pressure, turn the adjusting screw

counterclockwise.

3. To increase the gas pressure, turn the adjusting screw

clockwise.

NOTE: The correct manifold pressure for these furnaces is

3.65 IWG ± 0.3.

Adjustment Of Temperature Rise

The temperature rise (the difference of temperature between the

return air and the heated air from the furnace) must lie within the

range shown on the CSA rating plate and the data in Table 11.

After the temperature rise has been determined, the CFM can

be calculated as follows:

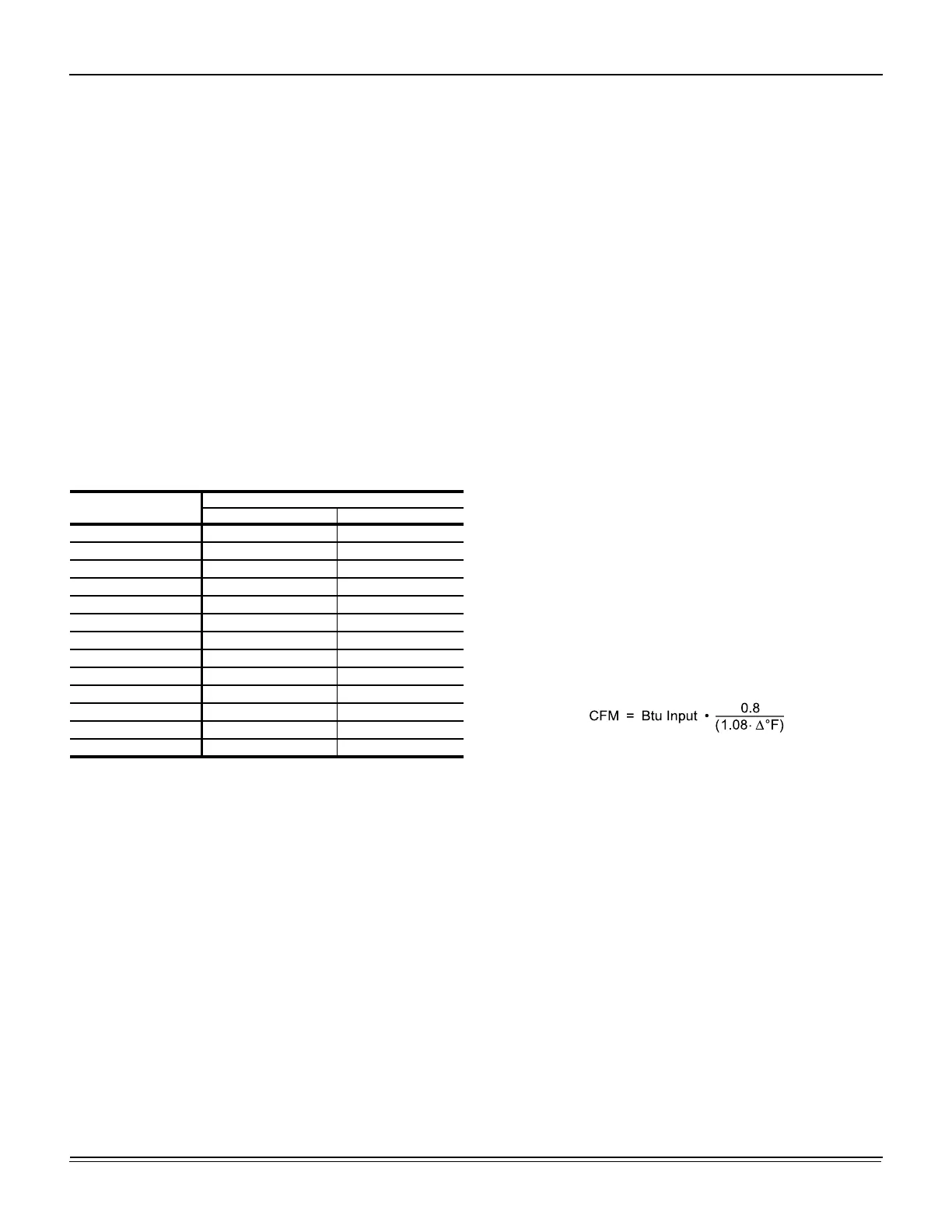

Table 24: Gas Rate Cubic Feet Per Hour

Seconds for

One Rev.

Size of Test Dial

1/2 cu. ft. 1 cu. ft.

4 450 900

6 300 600

8 228 450

10 180 360

12 150 300

14 129 257

16 113 225

18 100 200

20 90 180

22 82 164

24 75 150

26 69 138

28 64 129

Loading...

Loading...