JOHNSON CONTROLS

PRE-

INSTALLATION INSPECTION OF EQUIPMENT

All units are factory tested to ensure safe operation

and quality assembly. Units are packaged and sealed

on shipping skids and shipped in first class condition.

Torn and broken packaging, scratched or dented

panels should be reported to carrier immediatel

Internal inspection of all units should be performed

prior to installation. Remove all access doors and

check for visual defects that can occur during

transport. Any problems found internally should be

reported to carrier and manufacturer immediately.

R

efrigerant circuit should be checked to ensure no

leaks have occurred during shipment. Install gauge

set to high and low pressure ports to confirm pressure

has been maintained and no leaks have occurred

during shipment. Repair any damage prior to

installat

ion to ensure safe operation.

Record any unit damage on the Bill of

Lading and report to carrier and factory

immediately. Shipping and handling

damages are not warranty items.

RIGGING

PRIOR TO MOUNTING UNIT, CHECK

INDIVIDUAL UNIT WEIGHTS (PAGE

AND VERIFY LIFTING CAPACITY OF

LIFTING EQUIPMENT EXCEEDS WEIGHT

OF UNITS BY SAFE MARGINS. FAILURE

TO DO SO MAY RESULT IN UNIT

DAMAGE, PERSONAL INJURY OR EVEN

DEATH.

To ensure safe installation of the unit when ceiling

mount application is specified, estimate the

approximate center of gravity of the unit. The

configuration of internal components for each unit is

different and weight is unevenly distributed.

DETERMIN

GRAVITY OF THE UNIT BY PERFORM

ING A TEST LIFT. LIFTING AN UNBAL

ANCED UNIT CAN CAUSE PERSONAL

INSTALLATION INSPECTION OF EQUIPMENT

All units are factory tested to ensure safe operation

and quality assembly. Units are packaged and sealed

on shipping skids and shipped in first class condition.

Torn and broken packaging, scratched or dented

panels should be reported to carrier immediatel

y.

Internal inspection of all units should be performed

prior to installation. Remove all access doors and

check for visual defects that can occur during

transport. Any problems found internally should be

reported to carrier and manufacturer immediately.

efrigerant circuit should be checked to ensure no

leaks have occurred during shipment. Install gauge

set to high and low pressure ports to confirm pressure

has been maintained and no leaks have occurred

during shipment. Repair any damage prior to

ion to ensure safe operation.

Record any unit damage on the Bill of

Lading and report to carrier and factory

immediately. Shipping and handling

damages are not warranty items.

PRIOR TO MOUNTING UNIT, CHECK

INDIVIDUAL UNIT WEIGHTS (PAGE

4)

AND VERIFY LIFTING CAPACITY OF

LIFTING EQUIPMENT EXCEEDS WEIGHT

OF UNITS BY SAFE MARGINS. FAILURE

TO DO SO MAY RESULT IN UNIT

DAMAGE, PERSONAL INJURY OR EVEN

To ensure safe installation of the unit when ceiling

mount application is specified, estimate the

approximate center of gravity of the unit. The

configuration of internal components for each unit is

different and weight is unevenly distributed.

GRAVITY OF THE UNIT BY PERFORM

-

ING A TEST LIFT. LIFTING AN UNBAL

-

ANCED UNIT CAN CAUSE PERSONAL

INSTALLATION SITE

LOCK ALL ELECTRICAL POWER SUP

PLY SWITCHES IN THE OFF POSITION

BEFORE INSTALLING THE UNIT.

URE TO DISCONNECT POWER SUPPLY

MAY RESULT IN ELECTRICAL SHOCK

Location -

To ensure unit operates at maximum

efficiencies, choose a dry indoor area where the

temperature is controlled between 40

Consideration of surrounding areas should be taken

when choosing a location to install the unit. Common

vibration and sound levels associated with commercial

equipment may be objectionable to people or

equipment.

Failure to allow adequate space betwee

units may result in poor unit perfor

mance and possible unit failure.

Install thermostats, supply air ductwork, and

return air ductwork (if applicable) so that each

unit will operate only in a single cooling or

heating zone. In order to assure prope

of condensate, both horizontal and vertical units

have sloped (self-

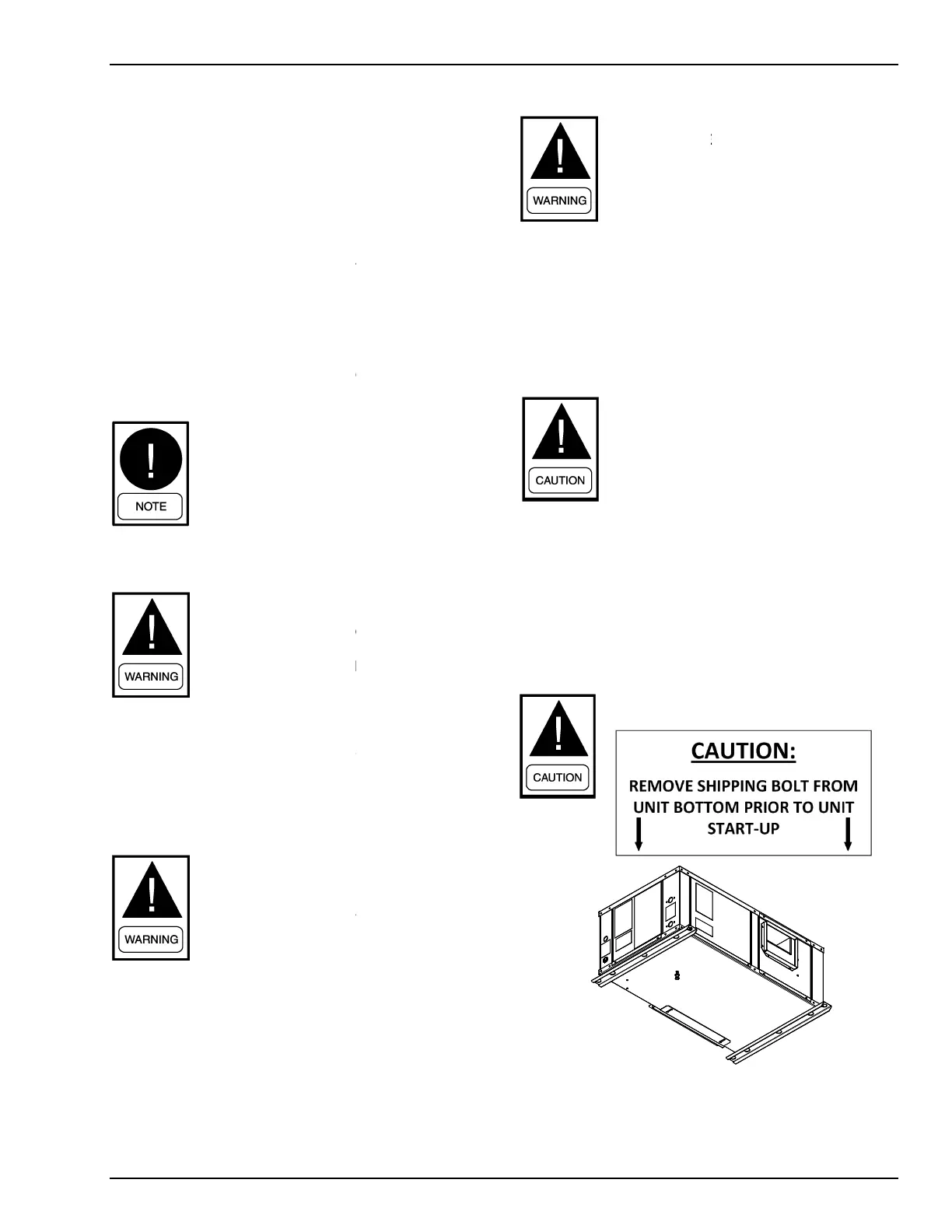

Failure to remove shipping bolt on RSH units m

result in piping damage and /or poor sound

performance.

FORM 145.16-IOM2 (0611)

7

LOCK ALL ELECTRICAL POWER SUP

-

PLY SWITCHES IN THE OFF POSITION

BEFORE INSTALLING THE UNIT.

FAIL-

URE TO DISCONNECT POWER SUPPLY

MAY RESULT IN ELECTRICAL SHOCK

To ensure unit operates at maximum

efficiencies, choose a dry indoor area where the

temperature is controlled between 40

°F and 115°F.

Consideration of surrounding areas should be taken

when choosing a location to install the unit. Common

vibration and sound levels associated with commercial

equipment may be objectionable to people or

Failure to allow adequate space betwee

n

units may result in poor unit perfor

-

mance and possible unit failure.

Install thermostats, supply air ductwork, and

return air ductwork (if applicable) so that each

unit will operate only in a single cooling or

heating zone. In order to assure prope

r drainage

of condensate, both horizontal and vertical units

Failure to remove shipping bolt on RSH units m

ay

result in piping damage and /or poor sound

Loading...

Loading...