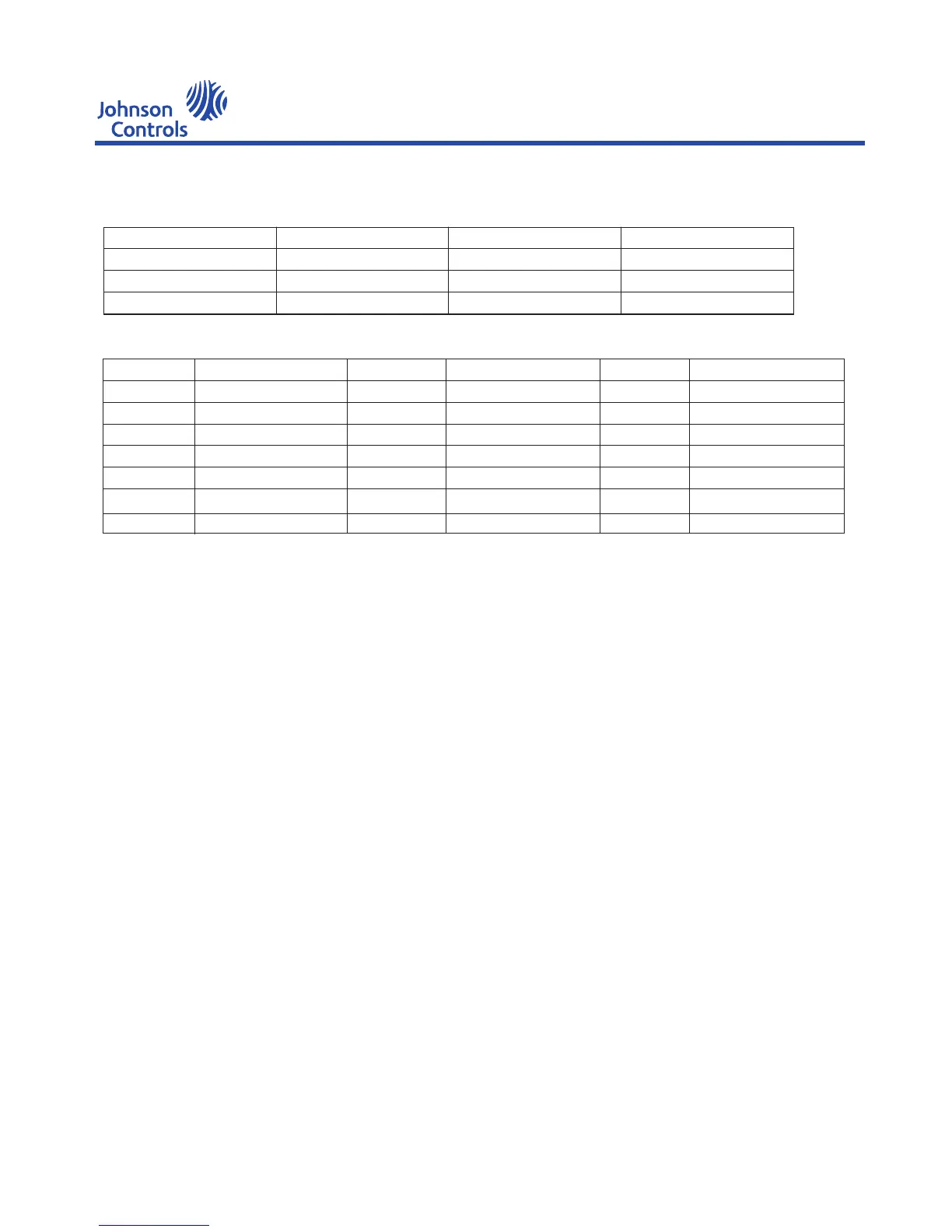

The corresponding of concentrations and freezing points of glycol solution

E.G wt%

5

10

15

Freezing point℃

-1.4

-3.28

-5.31

E.G wt%

20

26

30

Freezing piont℃

-7.8

-11.38

-14.04

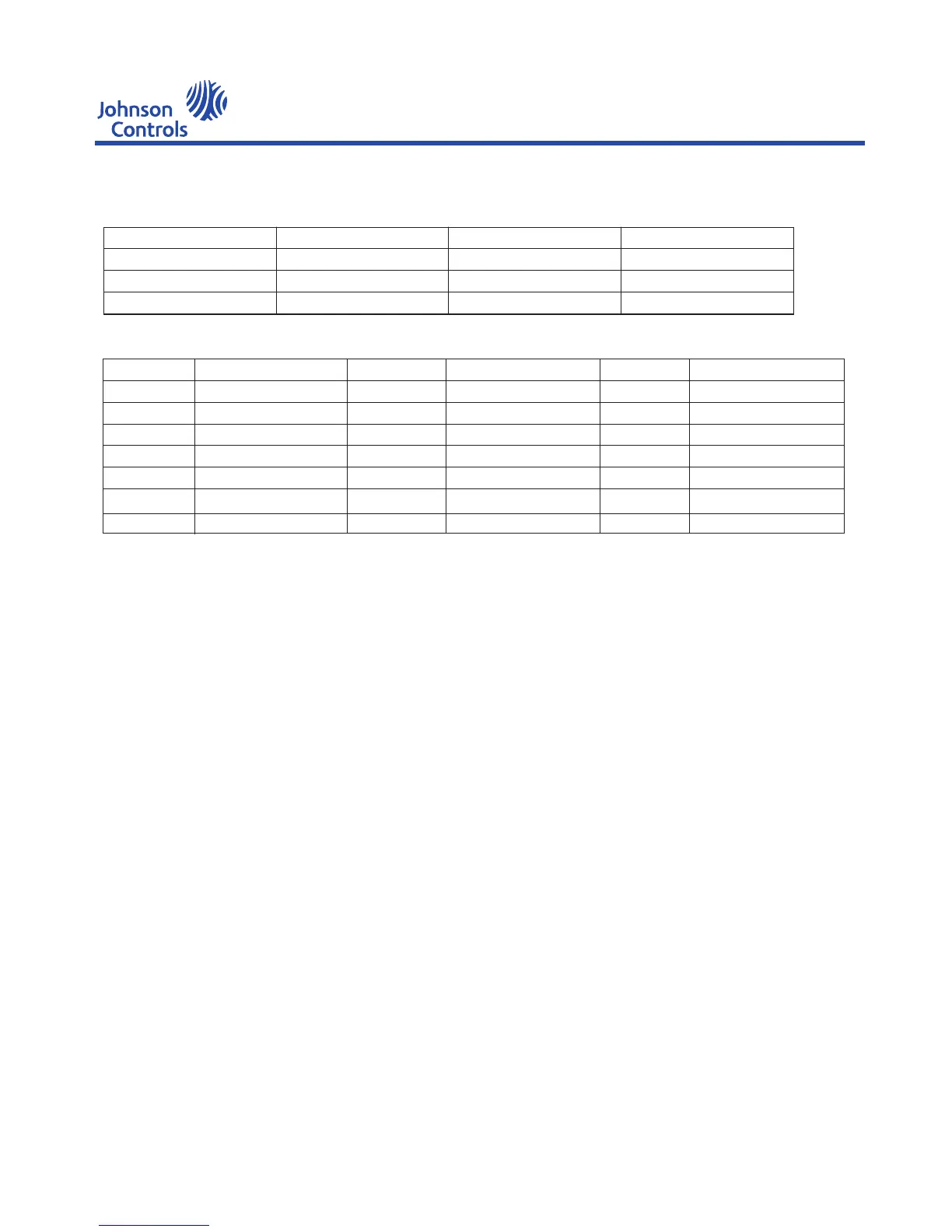

The saturated temperature of R134a in difference pressure

Pressure kpa

164

171

178

185

193

201

209

Saturated temperature ℃

-15

-14

-13

-12

-11

-10

-9

Pressure kpa

217

225

234

243

253

262

272

Saturated temperature ℃

-8

-7

-6

-5

-4

-3

-2

Pressure kpa

282

293

304

315

326

338

350

Saturated temperature ℃

-1

0

1

2

3

4

5

Flow Switch

Verify a chilled water flow switch is correctly fitted in the

,

customer s piping on the cooler outlet, and wired into the

control panel correctly using shielded cable.

Control panel pwer supply

Make sure that the control panel is power on and the

display screen can display normarly.

Programmed Options

Make sure all the options factory-programmed into the

Microprocessor Panel are in accordance with the cust-

,

omer s order requirements by pressing relevant Keys on

the keypad (Refer to instructions on the operation of

control System on section 5).

Programmed Settings

Make sure all the setpoints are in accordance with the

operating requirements by operating keypad (Refer to

instructions on the operation of control System on section

5).The setpoints of the chilled water temperature or hot

water temperature should be set according to the Unit

model and working conditions.

Time and Date

Setting the time/date by pressing relevant function Keys

on the keypad (Refer to instructions on the operation of

control System on section 5).

Startup/Stop arrangement

Setting the Startup/Stop arrangement in ordianary days

and holidays via the corresponding function keys.

(Refer to instructions on the operation of control System

on section 5).

Setpoints

Setting the setpoints and control range of the chilled/hot

water temperature(Refer to instructions on the operation

of control System on section 5).

Now the chiller is ready to work.

YEWS-E Water Cooling Screw Chiller/Heat Pump

50

Loading...

Loading...