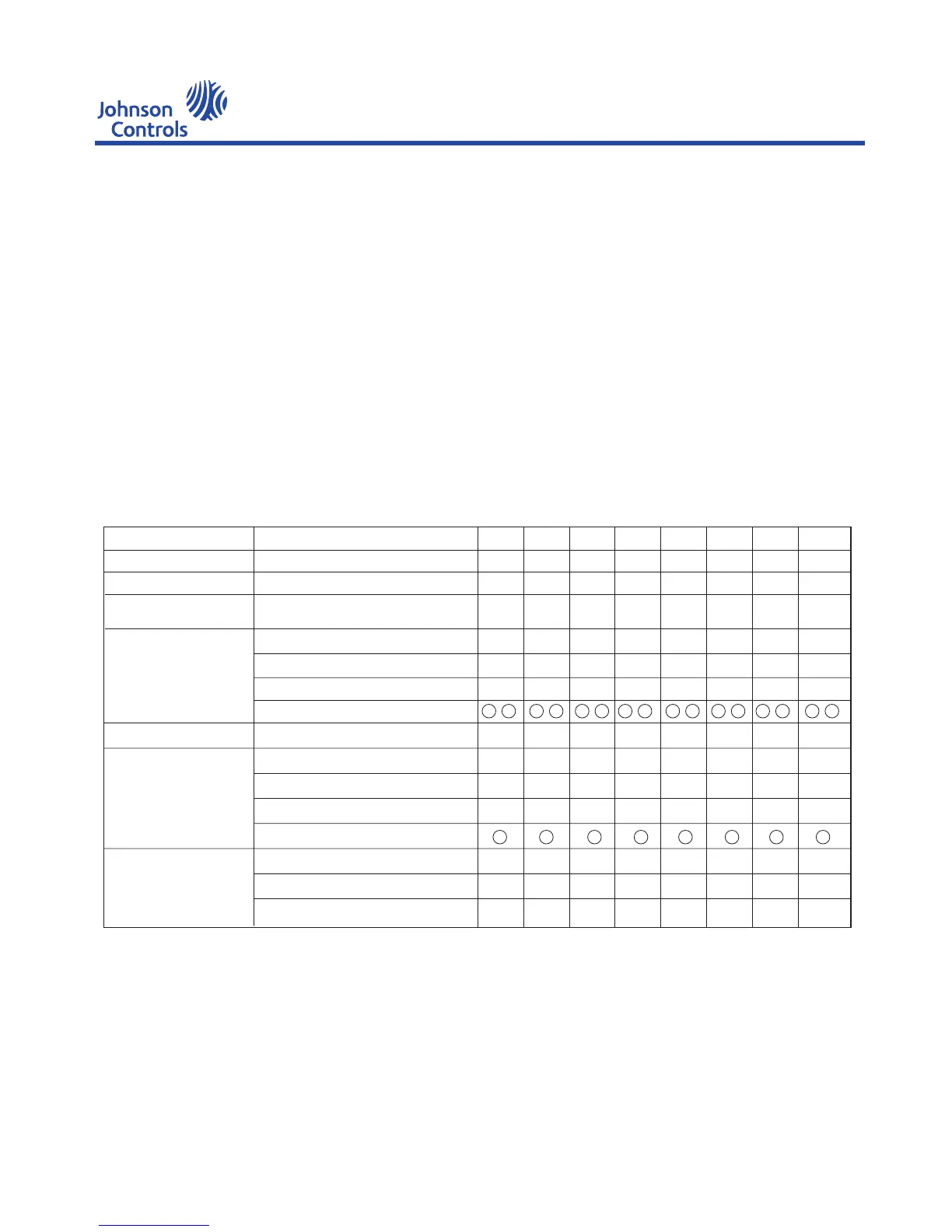

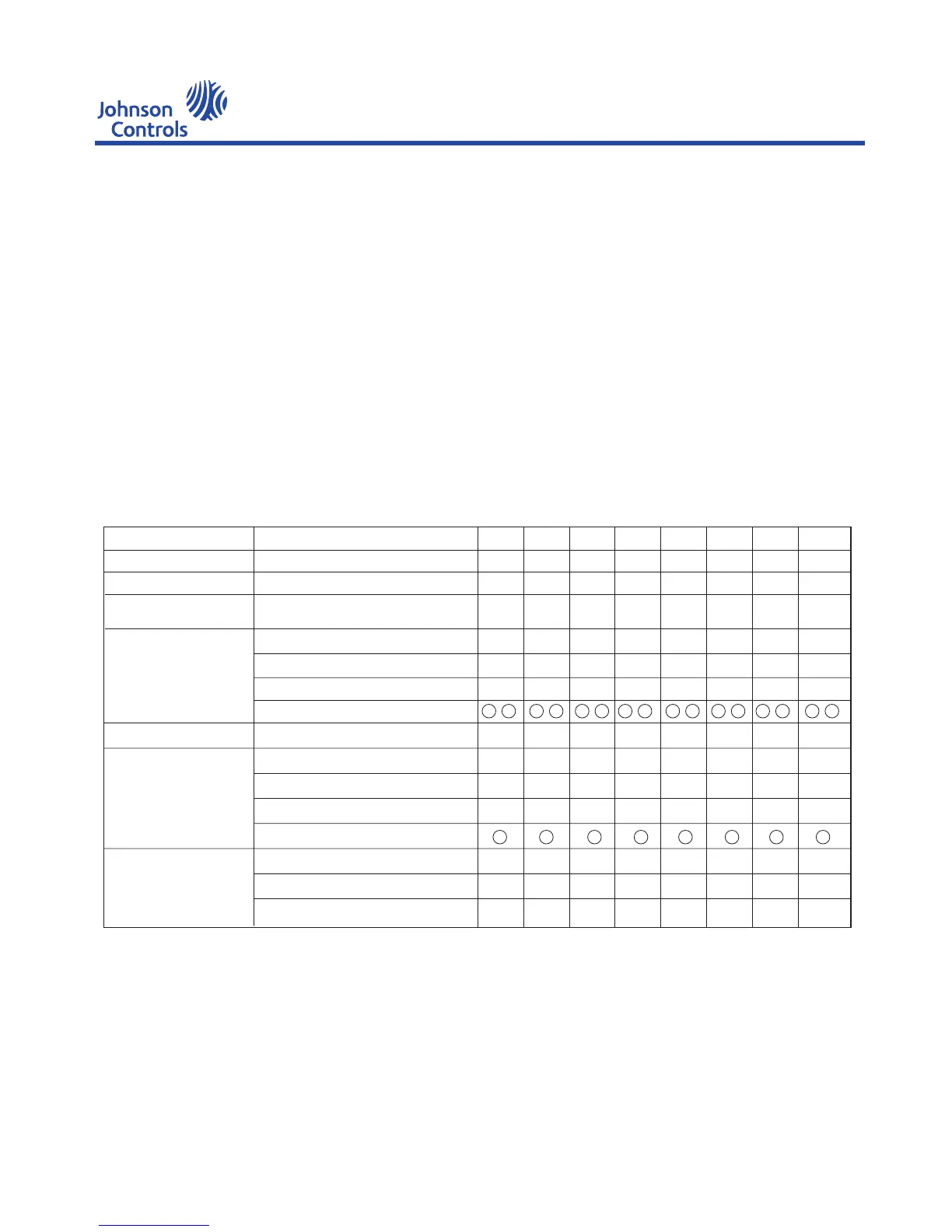

Date

Time

Runing hours

Motor

Evaporator

Condenser

Screw Chiller/Heat-pump Unit Record Table chiller situation:

100~215 TON model:

Compressor

Ambient

Tempearature

Yearly (or perform a more frequent inspection

according to the requirement)

1. Clearly drain out and replace the oil in oil separator

tank.

2. Evaporator and condenser

a. Inspect and clean the water drainage valve

b. Inspect and clean the pipes according to the requirements.

3. Inspect and maintain the electrical parts according to the

requirements.

4. Perform the chemical analysis to the system.

Dry-bulb/ Wet -bul

Evaporator pressure kPa

Discharge pressure kPa

Oil level (Seperator/compressor)

Current(A)

Entering Liquid temperature ℃

Leaving Liquid temperature ℃

Flow rate L/S

Liqudi level in sight galss

Entering Liquid temperature ℃

Leaving Liquid temperature ℃

Flow rate L/S

YEWS-E Water Cooling Screw Chiller/Heat Pump

Oil pressure kPa

55

Loading...

Loading...