10 JUDO PROFI-PLUS

Installation

4.1.2 Installed position

ATTENTION

(see chapter “Safety information and dan-

gers due to non-compliance”)

Always install the filter in a vertical position

(± 5°)!

Failure to observe this can cause uncon-

trolled backwashing water to escape and

can result in damage caused by water.

4.1.3 Mounting the built-in rotary

flanges

Install using the supplied built-in rotary

flange. The built-in rotary flange is used as a

connecting element between the pipe and

the filter.

It is suitable for both horizontal and vertical

pipes.

The built-in rotary flange must be in-

stalled in the direction of flow. This is

marked by a cast in arrow.

(see Fig. 5)

Failure to comply with this means the filter

cannot work.

ATTENTION

(see chapter “Safety information and dan-

gers due to non-compliance”)

The flange surface of the built-in rotary

flange must be in a horizontal position! The

built-in rotary flange must be fitted so that

mechanical stresses cannot occur! Other-

wise mechanical damage can result in the

built-in rotary flange. Otherwise mechanical

damage can result, the pipe may burst or the

built-in rotary flange can break. This can re-

sult in major water damage.

In this case, people close to the filter are ex-

posed to a health risk due to the large quan-

tities of water.

Therefore, during installation, ensure that no

large forces act on the pipe, built-in rotary

flange and filter.

4.1.4 Installing the filter

JPF

+

¾" - 1¼"

The built-in rotary flange for the filter is sup-

plied with bayonet drill holes. The necessary

seals and screws for this filter have already

been mounted.

Do not unscrew the screws!

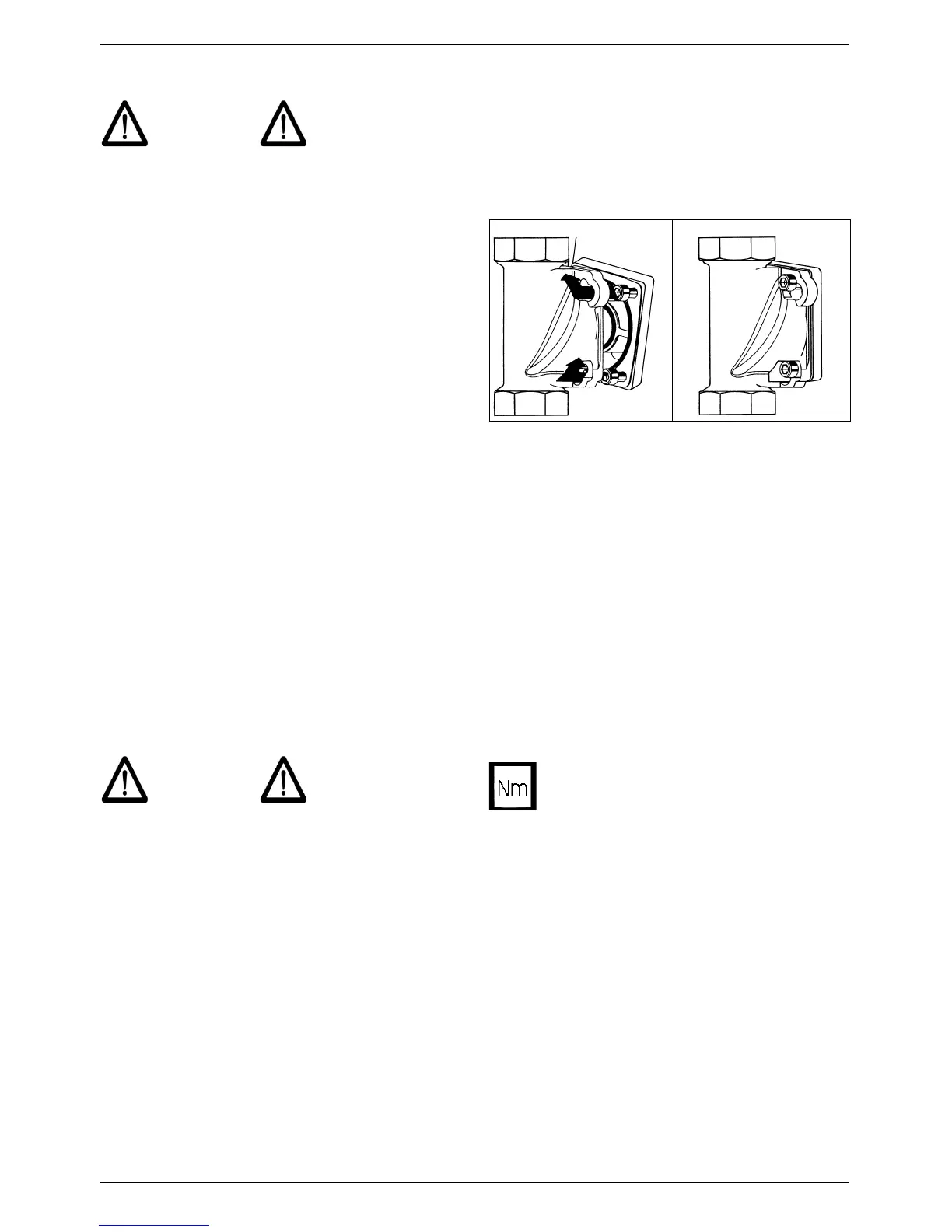

– insert the four flange screws in the bayo-

net drill holes on the built-in rotary flange

(see Fig. 5I).

– turn the filter in a clockwise direction as

far as it will go (see Fig. 5II).

– Tighten the four flange screws.

Fig. 5: Built-in rotary flange with Bayonet Fixture

Select the torque (approx. 4 Nm)

so that the gasket closes and the

filter is not damaged or strained.

I II

Loading...

Loading...