– 95 –

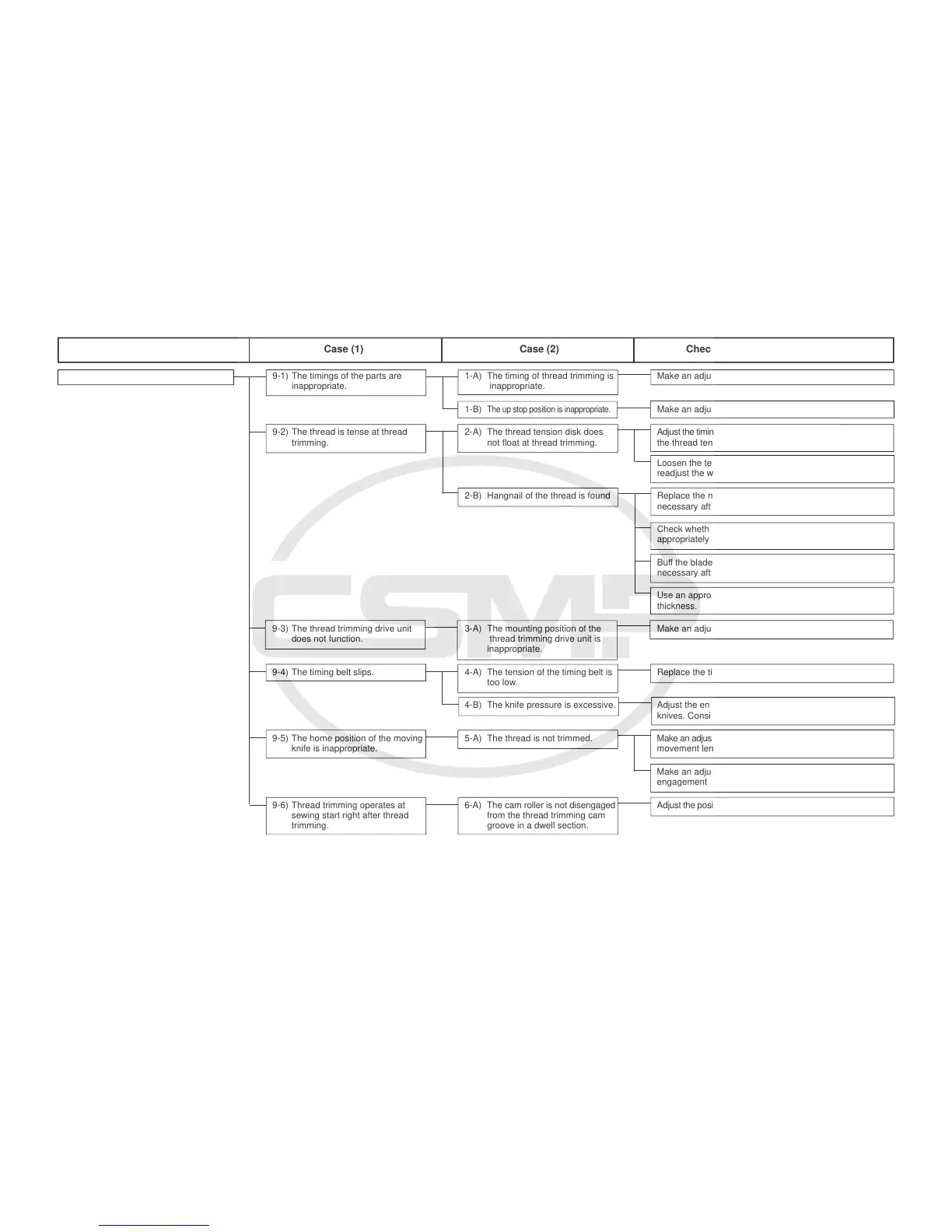

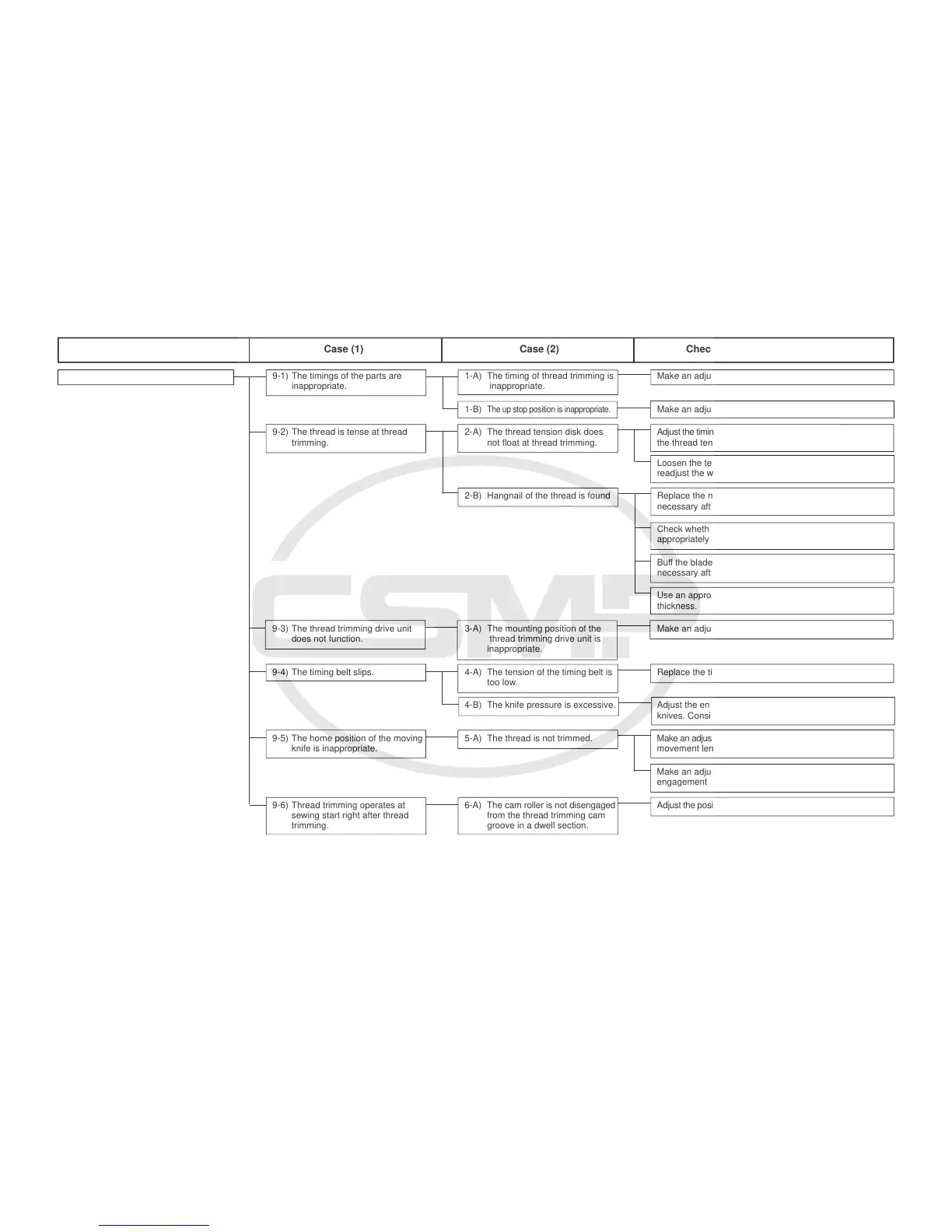

9. The moving knife breaks. 9-1) The timings of the parts are 1-A) The timing of thread trimming is Make an adjustment with reference to 3. -(11)-3).

inappropriate. inappropriate.

1-B)

The up stop position is inappropriate.

Make an adjustment with reference to 3.-(10)-1).

9-2) The thread is tense at thread 2-A) The thread tension disk does Adjust the timing of the disk floating with use of the setscrew of

trimming. not float at thread trimming. the thread tension unit.

Loosen the tension release wire presser (bottom) and

readjust the wire position.

2-B) Hangnail of the thread is found Replace the needle with new one or a ballpoint needle if

necessary after checking the needle tip.

Check whether the timing and clearance of the hook are

appropriately adjusted.

Buff the blade top of the hook or other thread paths if

necessary after checking them.

Use an appropriate gauge and needle for the thread

thickness.

9-3) The thread trimming drive unit 3-A) The mounting position of the Make an adjustment with reference to 3.- (11)-11.

does not function. thread trimming drive unit is

inappropriate.

9-4) The timing belt slips. 4-A) The tension of the timing belt is Replace the timing belt.

too low.

4-B) The knife pressure is excessive. Adjust the engagement between the moving and counter

knives. Consider the correction of the counter knife, too.

9-5) The home position of the moving 5-A) The thread is not trimmed. Make an adjustment with reference to 3. -11)-4). (for backward

knife is inappropriate. movement length of the moving knife)

Make an adjustment with reference to 3.-(11)-5). (for

engagement with the counter knife)

9-6) Thread trimming operates at 6-A) The cam roller is not disengaged Adjust the position relation between the cam groove and roller.

sewing start right after thread from the thread trimming cam

trimming. groove in a dwell section.

Trouble Case (1) Case (2) Check and Corrective measures

Loading...

Loading...