5. Applying grease

(1) Applying grease

For the safe usage of a sewing machine, periodically apply a grease (once every 2 or 3 years for standard)

to the application spots specied for each model, by means of a cotton applicator or the like. For using the

SC-922, an alarming sound is generated when the time for grease-up comes. When this alarming is heard, a

grease-up action has to be taken.

(Caution) 1. Never feed oil to the grease-up spots.

2. It must be noted that too much grease application may result in grease leakage from

the thread take-up lever cover section or the needle bar.

(2) Greasing points

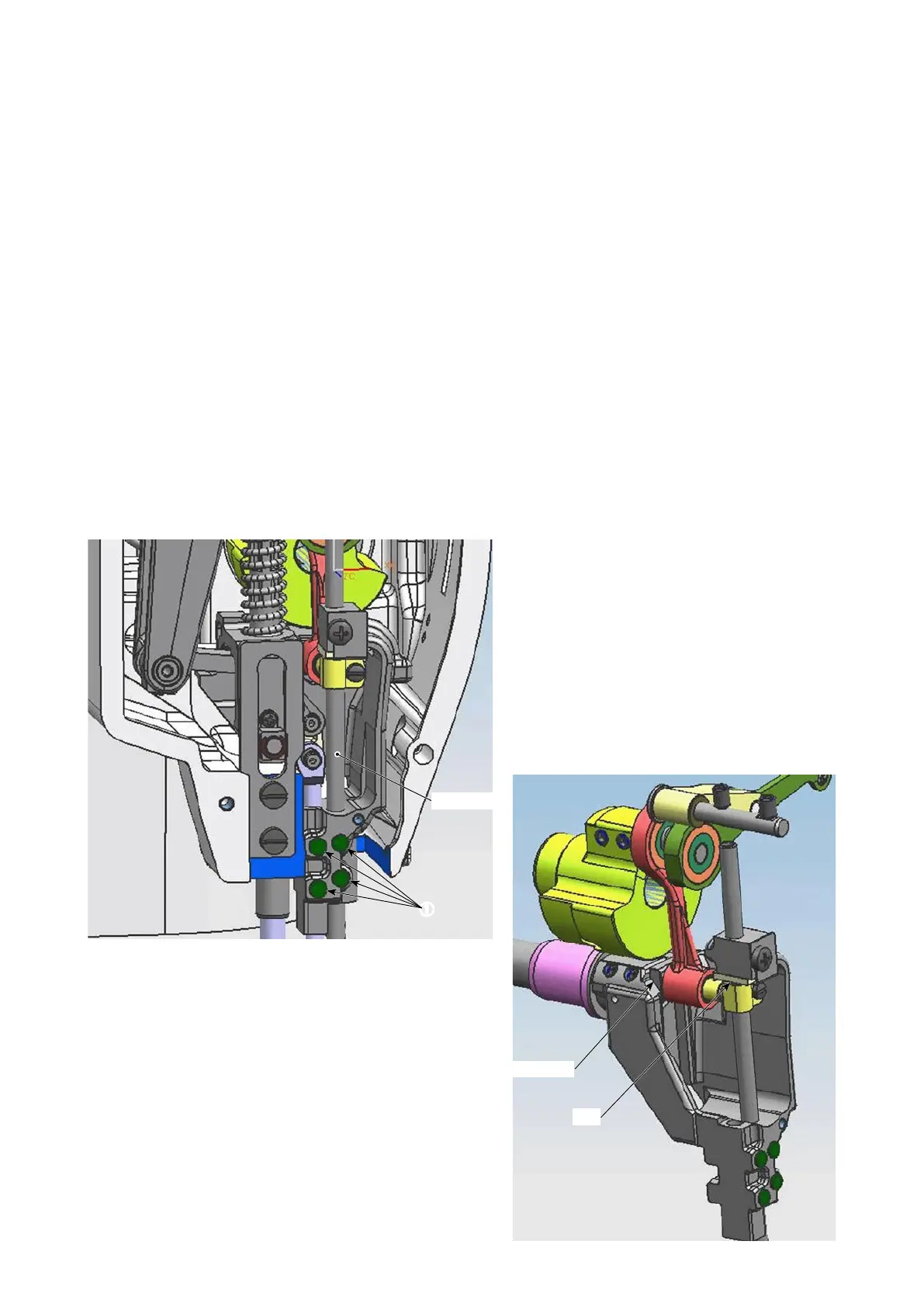

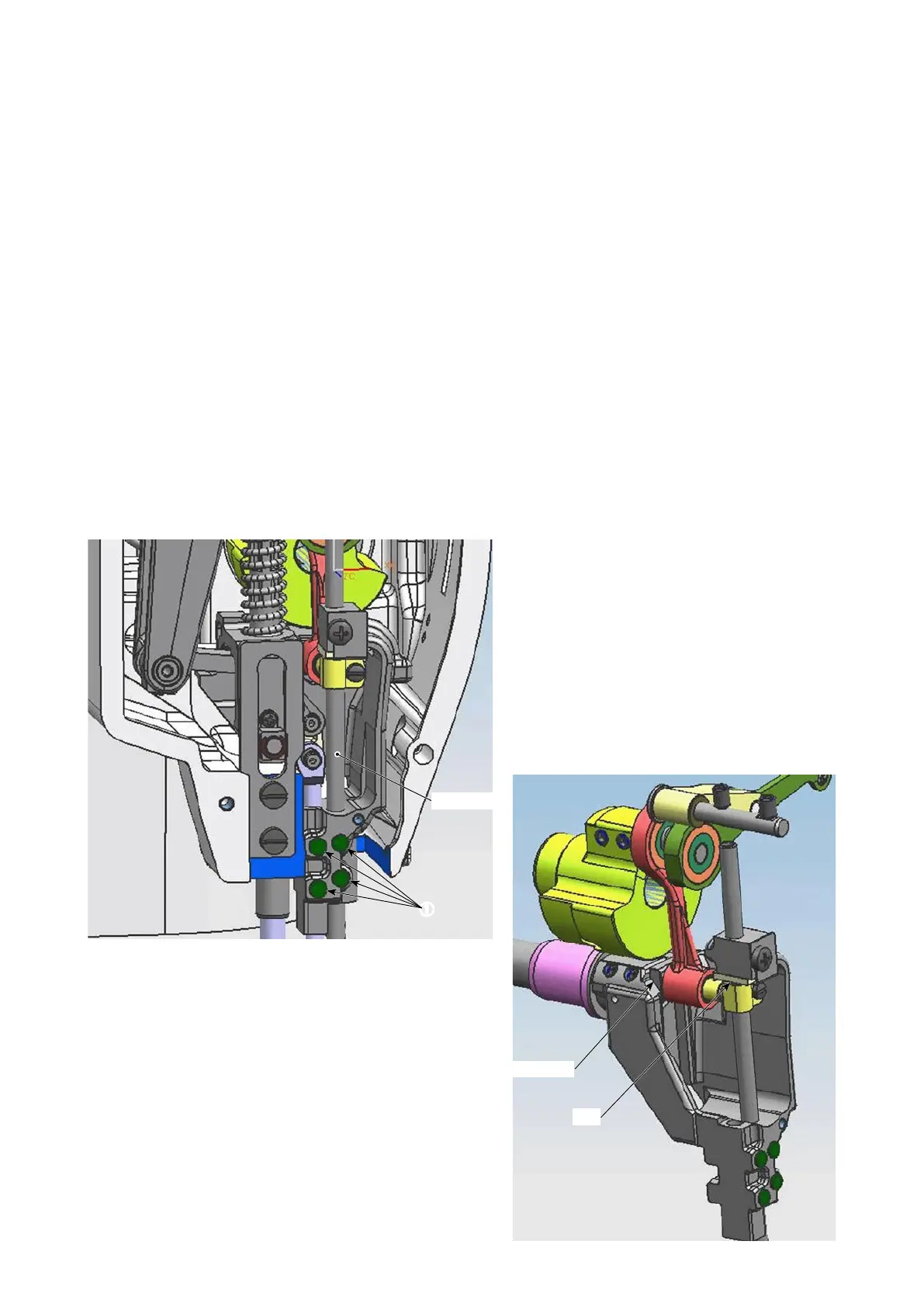

1) Needle bar rocking base

1. Remove face plate.

2. Remove rubber plugs

1

.

3. Fill grease holes with JUKI Grease A.

4. Attach rubber plugs

1

.

5. Wipe off grease that was exposed.

6. Attach face plate.

Slide block

Felt

1

Needle bar

海外講習会用121122LU-2810(-7)EM

Loading...

Loading...