−36 −

4

Adjustment Procedures Results of Improper Adjustment

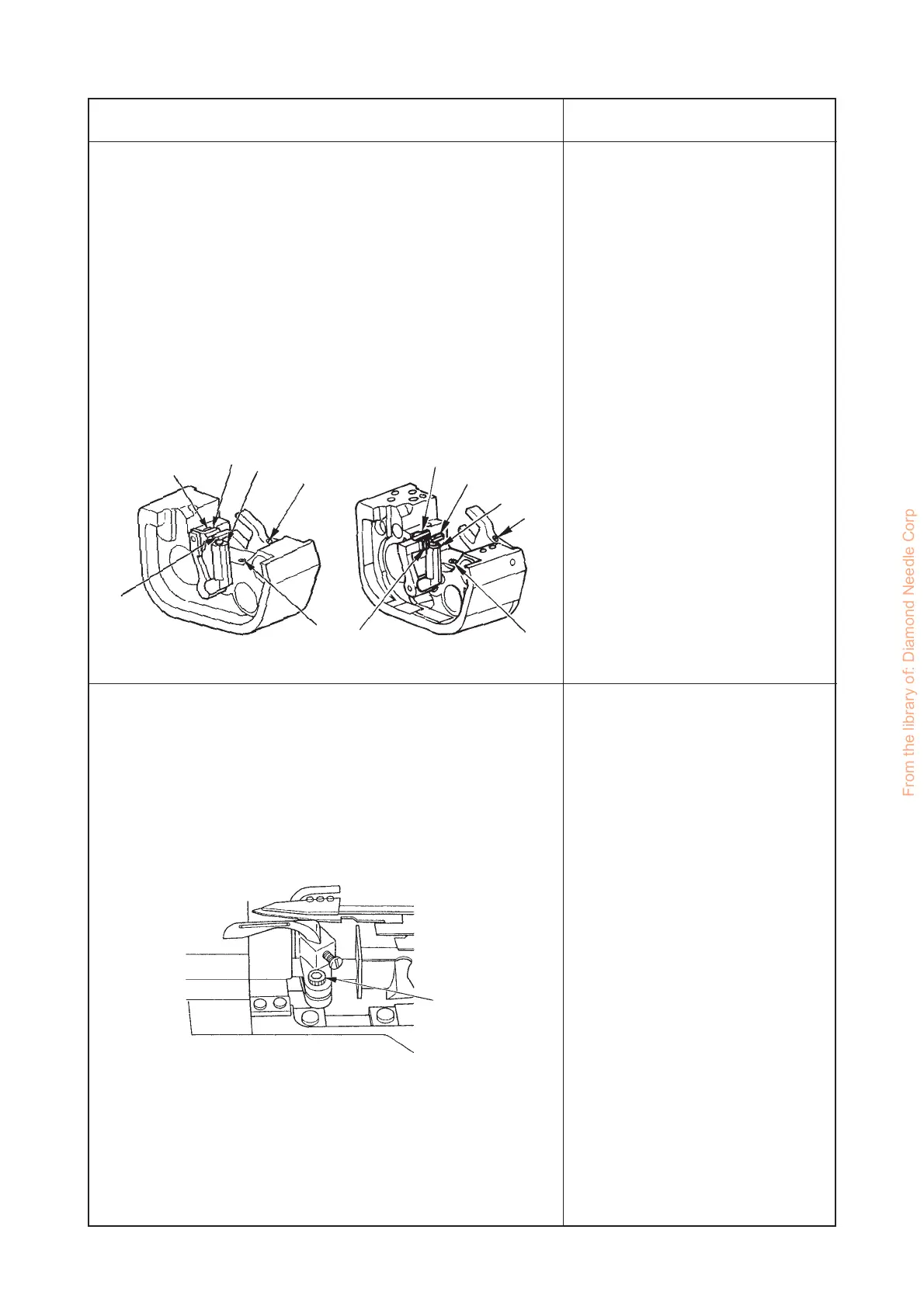

™ If the clearance between the rear

needle guard and the needle is

large, it causes the skipping

stitch, the damage of the blade

point of the looper and needle

breakage.

™ If the rear needle guard and the

needle hits strongly, it will cause

the damage of the needle top.

™ If the clearance between the

front needle guard and the

needle is large, the loop

becomes small and the skipping

stitch will occur.

™ If the front needle guard and the

needle hits strongly, the loop

becomes large and the skipping

stitch, the damage of the needle

point and the damage of the

blade point of the looper will

occur.

™ Adjust the height of the rear needle guard by loosening the

screw !2 and move the rear needle guard !1 up and down.

Adjust the pushing amount by loosening the screw !3 and move

the rear needle guard back and forth.

™ Adjust the height of the front needle guard by loosening the

screw !5 and move the front needle guard !4 up and down.

Adjust the inclination at the same time. Adjust the clearance

for the needle by loosening the screw !6 .

(Caution) Use a 3/32" hexagonal wrench for the screw !3.

Check that there is no looseness on the left/right

sides of the rear needle guard when tightening the

screw !3.

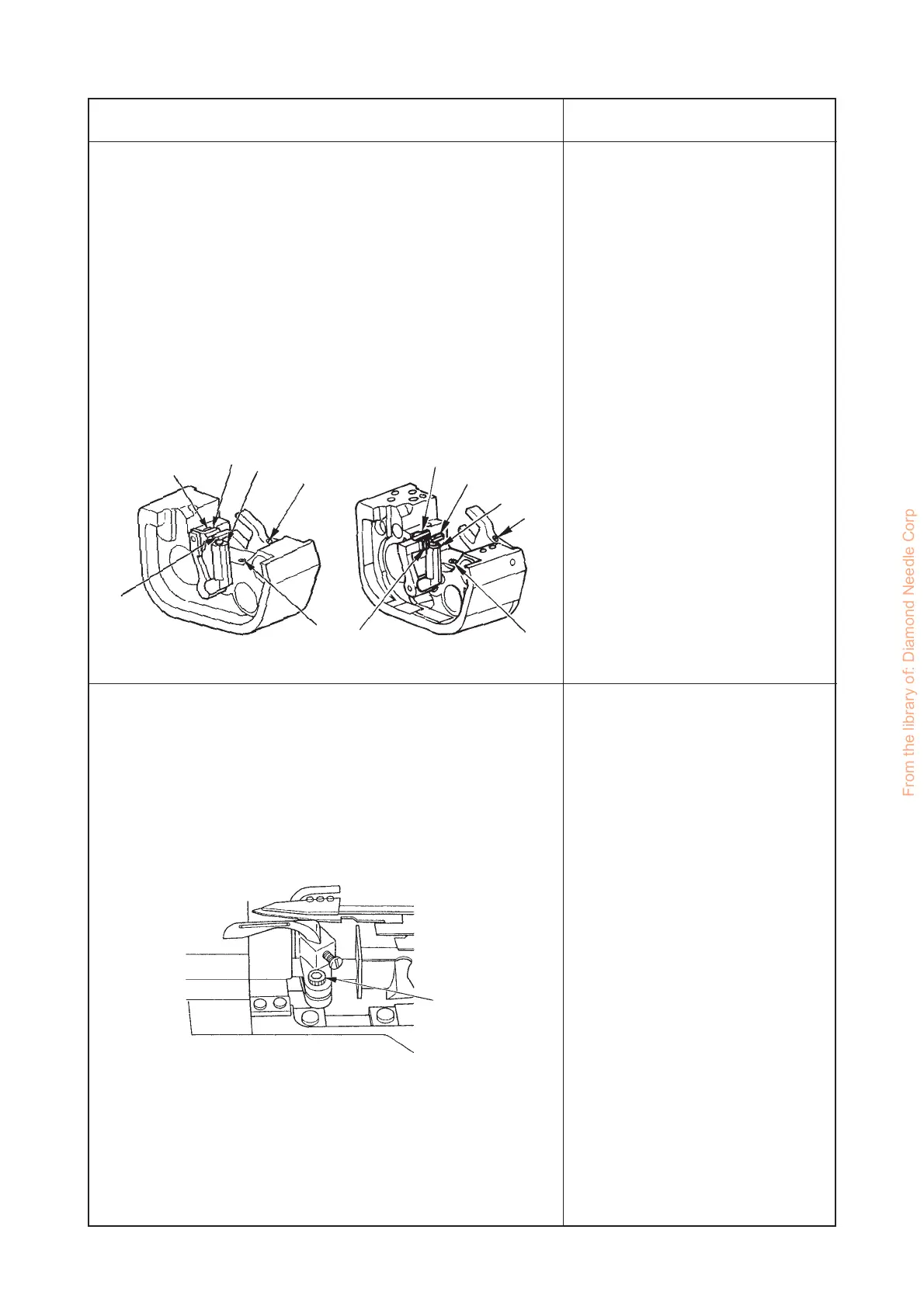

™ Adjust by loosening the looper base setscrew 4 and move

the looper holder back and forth.

™ If the clearance is large, skipping

stitch of the needle thread

scooping occurs. And the

damage of the needle point will

occur due to the strong hit on the

back of the looper.

™ If the clearance is small, the

damage of the blade point of the

looper and the needle breakage

will occur. And, the skipping

stitch will occur as the clearance

between the back of the looper

and the needle becomes large.

(Old type) (New type)

!6

!3

!5

!1

!2

!4

!1

!2

!3

!4

!5

!6

From the library of: Diamond Needle Corp

Loading...

Loading...