−54 −

Adjustment Procedures Results of Improper Adjustment

™ Too small overlapping amount of

catching part in pointed end of

movable knife with the stationary

knife disables cutting of looper

thread.

™ Too much distance from the

pointed end of movable knife to

the top end of clamp spring

disables clamping.

™ Too small distance from the

stationary knife to the top end of

flat spring could cause improper

clamping; too much distance

could disturb smooth thread

threading.

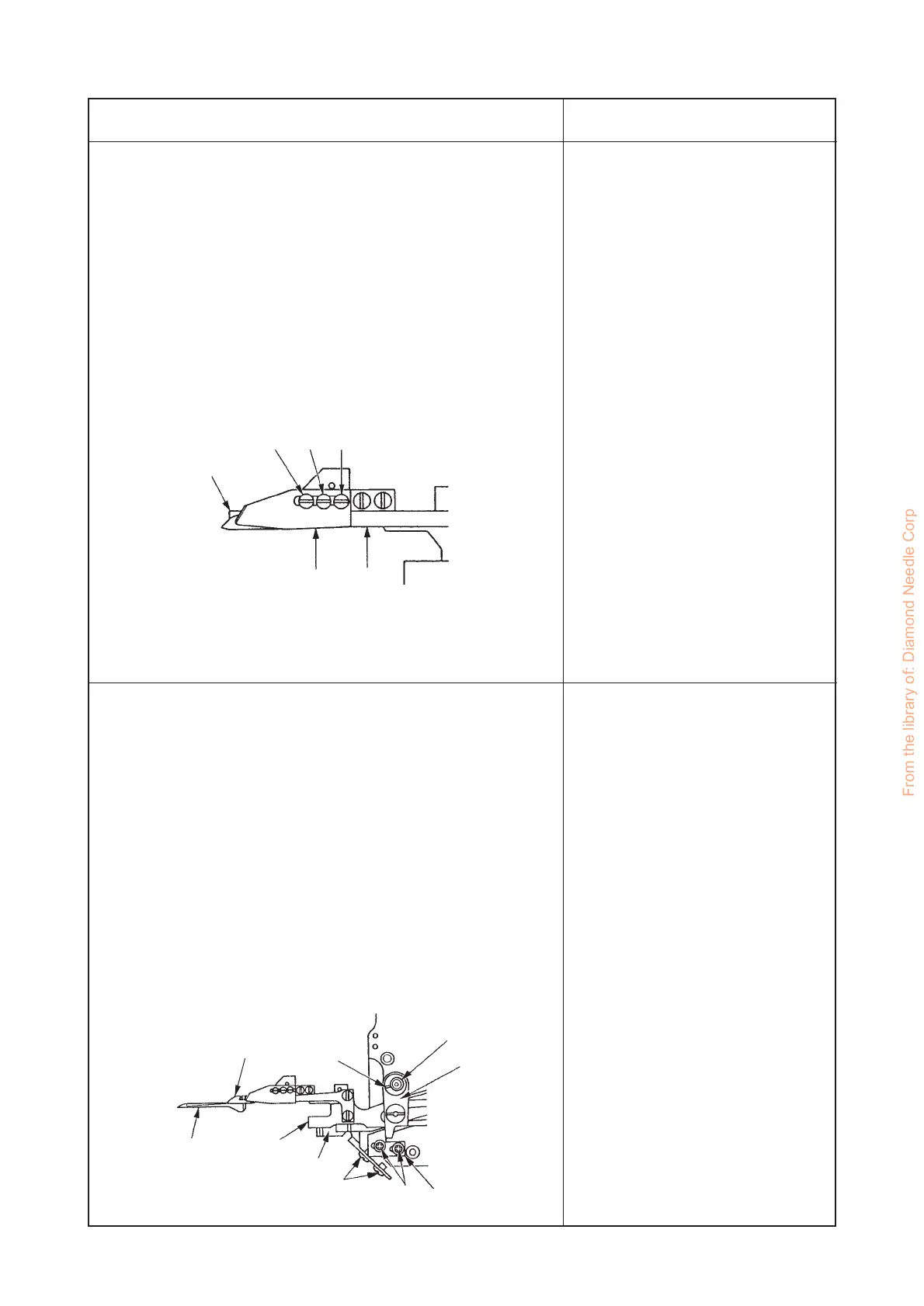

For the adjustment of stationary knife 9 and clamp spring !1 ,

loosen 2 screws 7 and a screw 8 .

Be sure to retain the screw 8 which adjusts the clamping pressure

after thread trimming and make adjustment of clamping pressure

so that looper thread comes off about 3 stitches after start of

sewing.

Mount the clamp spring !1 and stationary knife 9 so that they

are parallel to the side of movable knife !0.

When looper moves forward all the way to its limit, push on the

solenoid so that the pointed end of stationary knife is situated

12.5 mm ahead from the rear of looper. In this state :

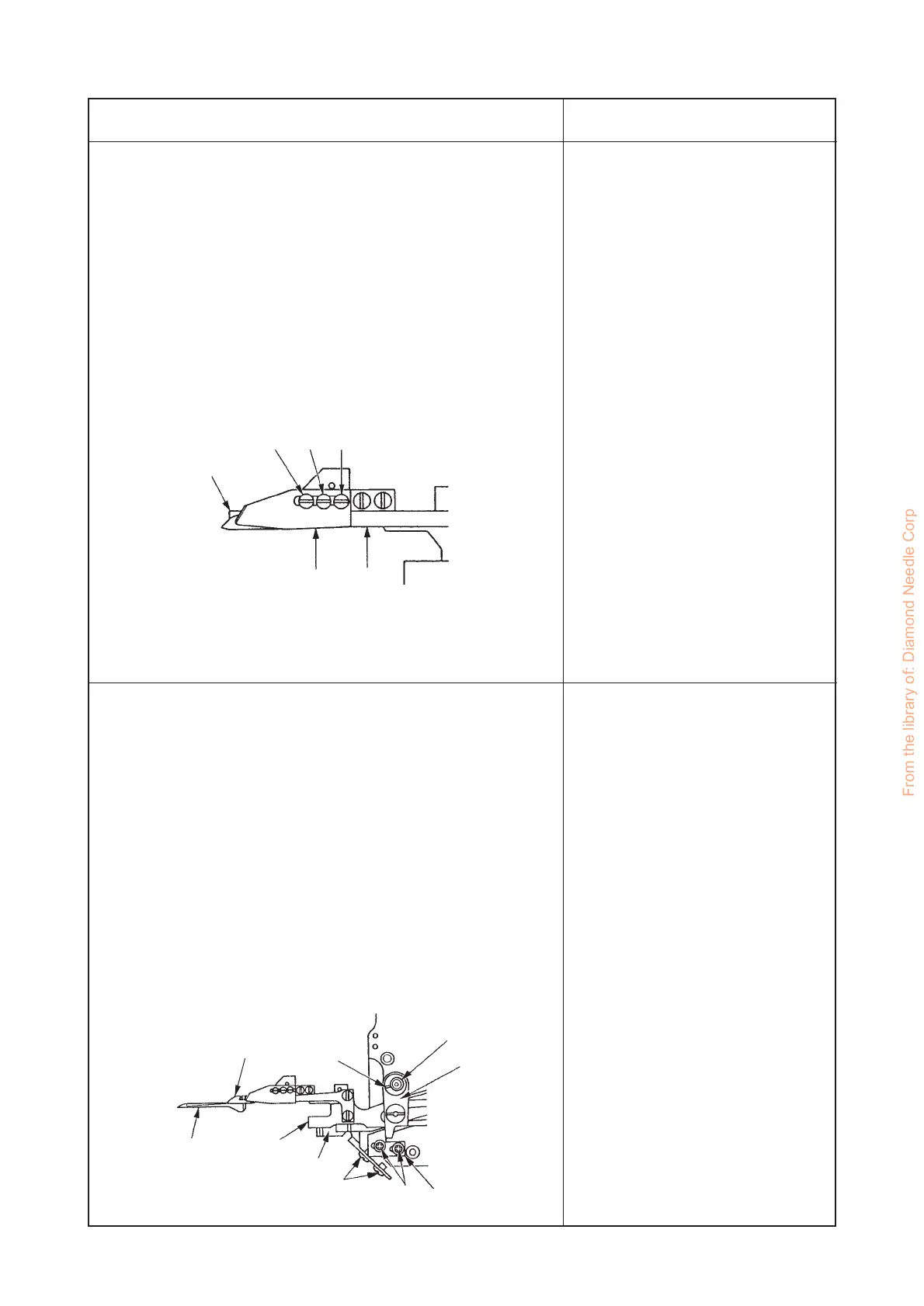

™ Loosen the screw !9 so that the pointed end of stationary knife

comes to the ridgeline in the flat section of looper top face(Refer

to the left illustration), and make adjustment by turning the

eccentric @0 .

™ Adjust stopper plate !5 by loosening 2 screws !4, adjust stopper

plate so as clamp spring just clears rear of looper.

™ Loosen the 2 screws !8 , and move up and down the guide !6

so that the guide !6 is in contact with the underside of movable

knife !7 and the clearance between the movable knife !0 and

the upper face of lower looper !3 is to be 0.1mm.

™ Incorrect adjustment could

cause the failure of thread

cutting and the thread cast-off at

the start of sewing.

!1

7

78

9

!0

!9

@0

@1

!3

!7

!6

!8

!4 !5

!0

From the library of: Diamond Needle Corp

Loading...

Loading...