−60 −

$2

$6

$7

™ Incorrect adjustment could

cause defective stitch or stitch

skip.

™ Too short length of remaining

needle thread could cause the

needle thread to pull out of

needle eye cause stitch skip at

the start of sewing.

™ Too long length of remaining

needle thread could produce

foul seam at the start of sewing.

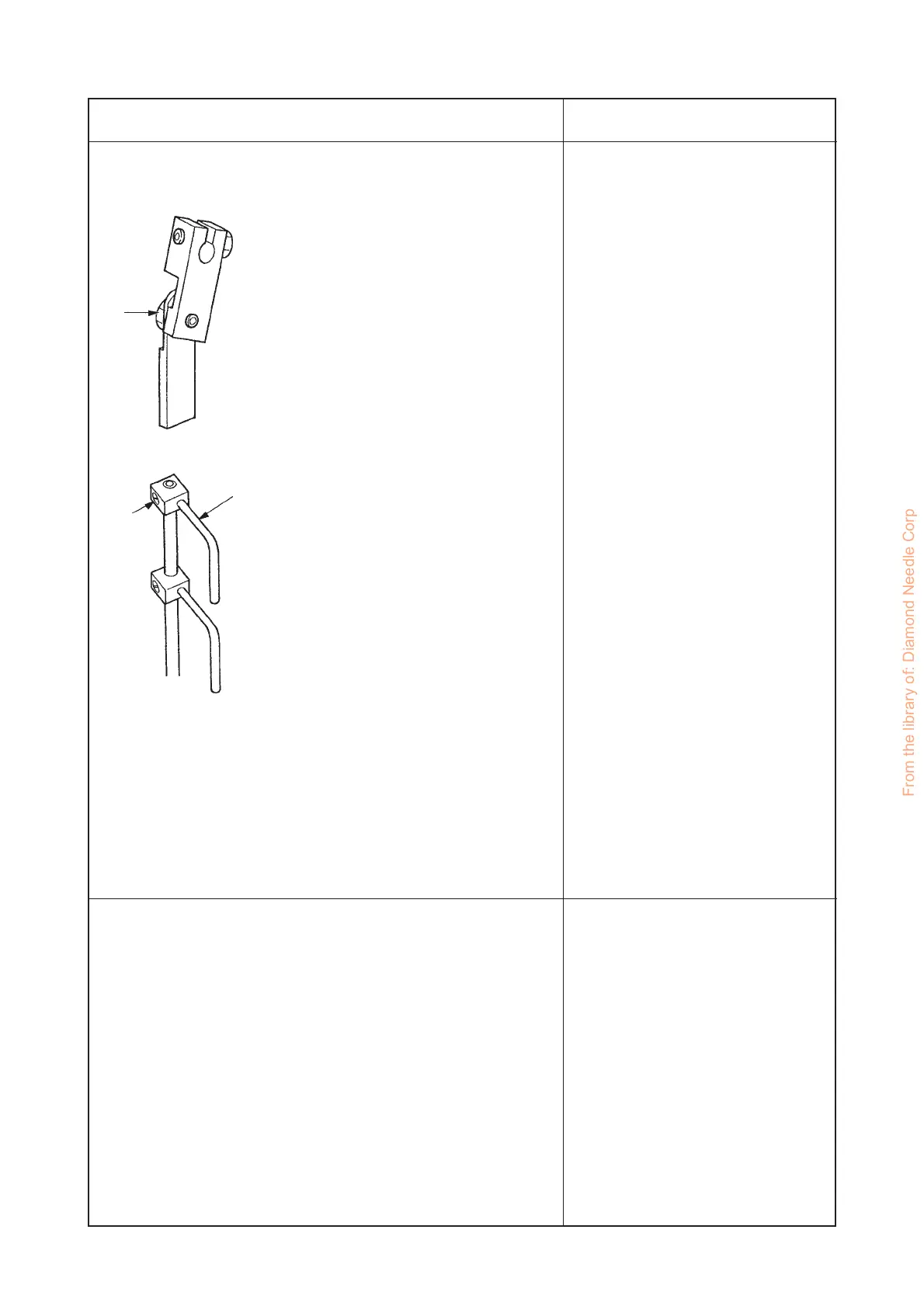

1 Disc float timing

™ Make a provisional adjustment by

loosening screw #8 so that it is

situated at the center of eccentric

nut #9 adjusting range.

™ Loosen the screw $0 . Move the

thread tension release lever $1 so

that the tongue #6 just contacts the

thread tension disc #7 .

™ Remove the hinge screw $2 to confirm

that thread trimmer mechanism and

thread tension release mechanism

work smoothly.

™ Loosen the screw $6 , and move up

and down the thread tension

release hook $7 .

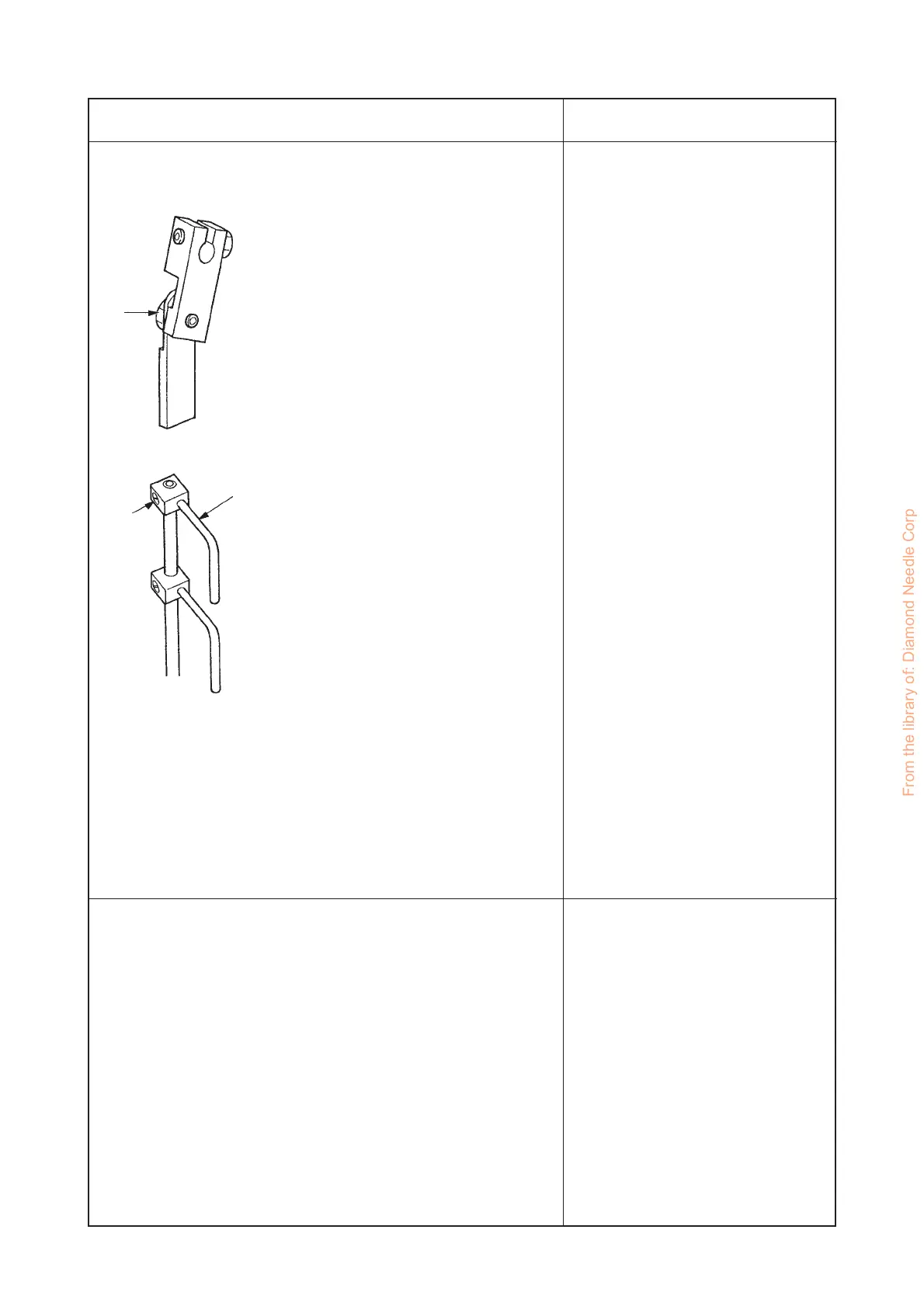

Loosen the nut. Make the adjustment of clearance between the

contactless switch and plate %00 by moving the contactless switch

$8 by loosening 2 nuts $9.

Confirm the LED’s OFF during operation and ON under the normal

state by actually cutting the thread several times.

™ Too large clearance disables the

running of motor.

™ Too short clearance enables the

running of motor due to the

defective return of thread

trimmer, which could be the

cause of the motor damage.

Adjustment Procedures Results of Improper Adjustment

From the library of: Diamond Needle Corp

Loading...

Loading...