−66 −

Adjustment Procedures Results of Improper Adjustment

Adjustment Procedures Results of Improper Adjustment

™ Adjust the vertical position of needle bar cam plate 4 and

longitudinal position of needle bar fork thread take-up 6 so

that the hole for the right needle of needle bar fork thread take-

up 6 is as shown in the figure on the left-hand side when the

needle bar is at its lower dead point. At this time, assemble so

that the clearance in the lateral direction between needle bar

fork thread take-up 6 and needle bar cam plate 4 should be

equal.

(Caution) See the item (1) Parts used.

<When excessively hard-to-slip

thread is used>

Needle bar cam plate

... Set it higher by 1 to 1.5 mm.

Needle bar fork thread take-up

... Adjust it to the front side.

<When easy-to-slip thread is used>

Needle bar cam plate

... Keep as it is.

Needle bar fork thread take-up

... Adjust it to the rear side.

Horizontal direction : 53 mm from

the right-hand side of “needle bar

cam plate 4”

Height direction : (From the top end

of needle thread eyelet installing

base to the bottom end of the hold

of the thread guide)

<When desired to decrease the

tension with light-weight materials>

Increase the whole adjustment

values by 1 to 2 mm.

<When thread breakage occurs

frequently with heavy-weight

materials>

Decrease the whole adjustment

values by 1 to 2 mm.

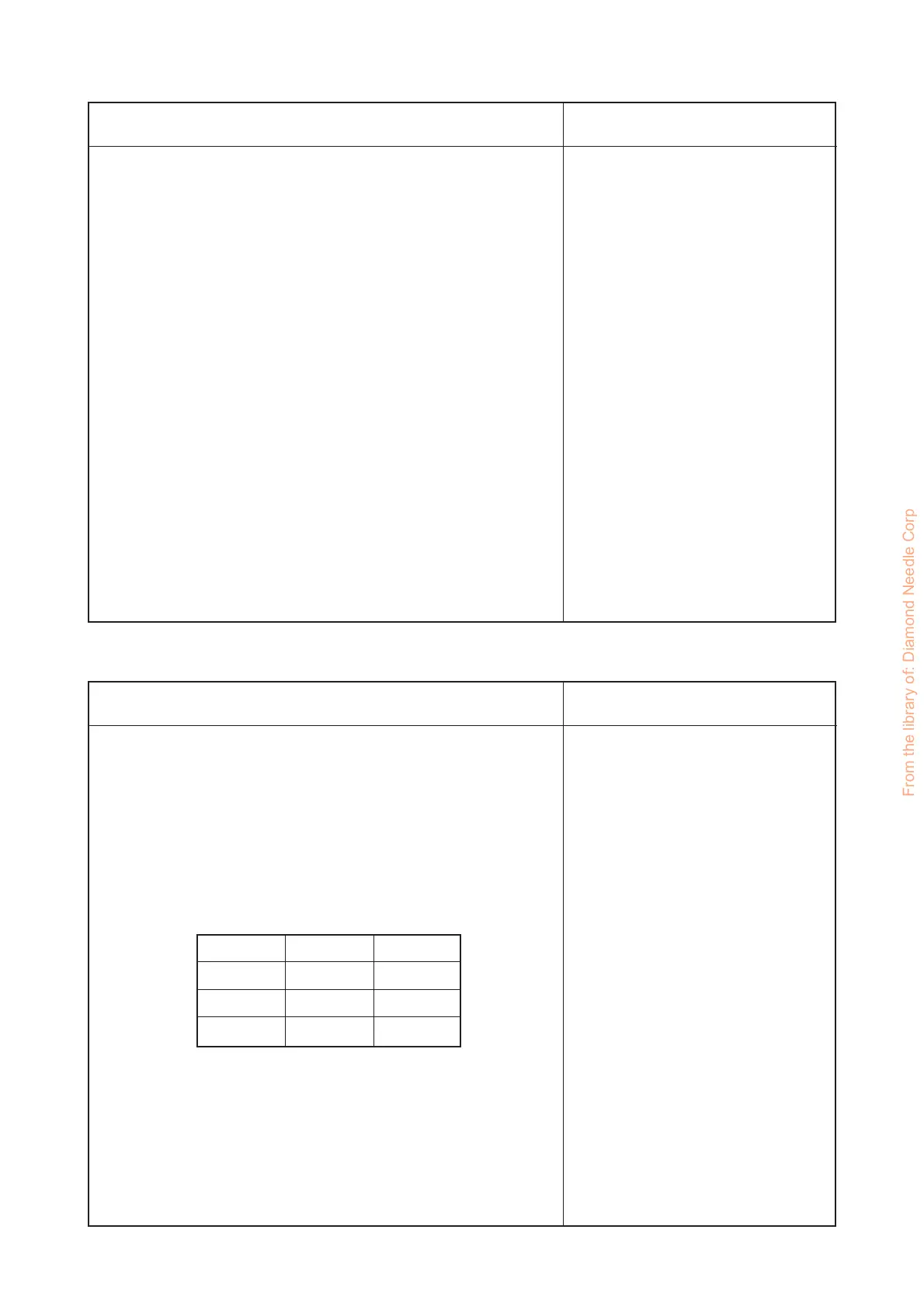

™ Remove needle thread eyelet installing base !0 with the thread

guide !1 from silicone thread lubricator (asm.) 9.

™ Temporarily set needle thread eyelet installing base !0 to

medium thread path base 7.

™ Tighten medium thread path base 7 by using the setscrew

located at the upper side of the auxiliary thread take-up cover.

™ Adjustment value of needle thread eyelet !1 is as described

below.

(Caution) See the item (1) Parts used.

MFC MF

A (left) 15 mm 22 mm

B (center) 19 mm 25 mm

C (right) 21 mm 29 mm

From the library of: Diamond Needle Corp

Loading...

Loading...