F 5

0803.GB

a) Wheel bolts to be first checked for tightness after approx. 100 operating hours; tighten, if

necessary.

b) Hydraulic connections to be first checked for leakage after approx. 100 operating hours;

tighten, if necessary.

c) First change after 500 operating hours.

A

The maintenance intervals refer to normal service conditions. In case of aggravated

conditions, the intervals must be reduced as required.

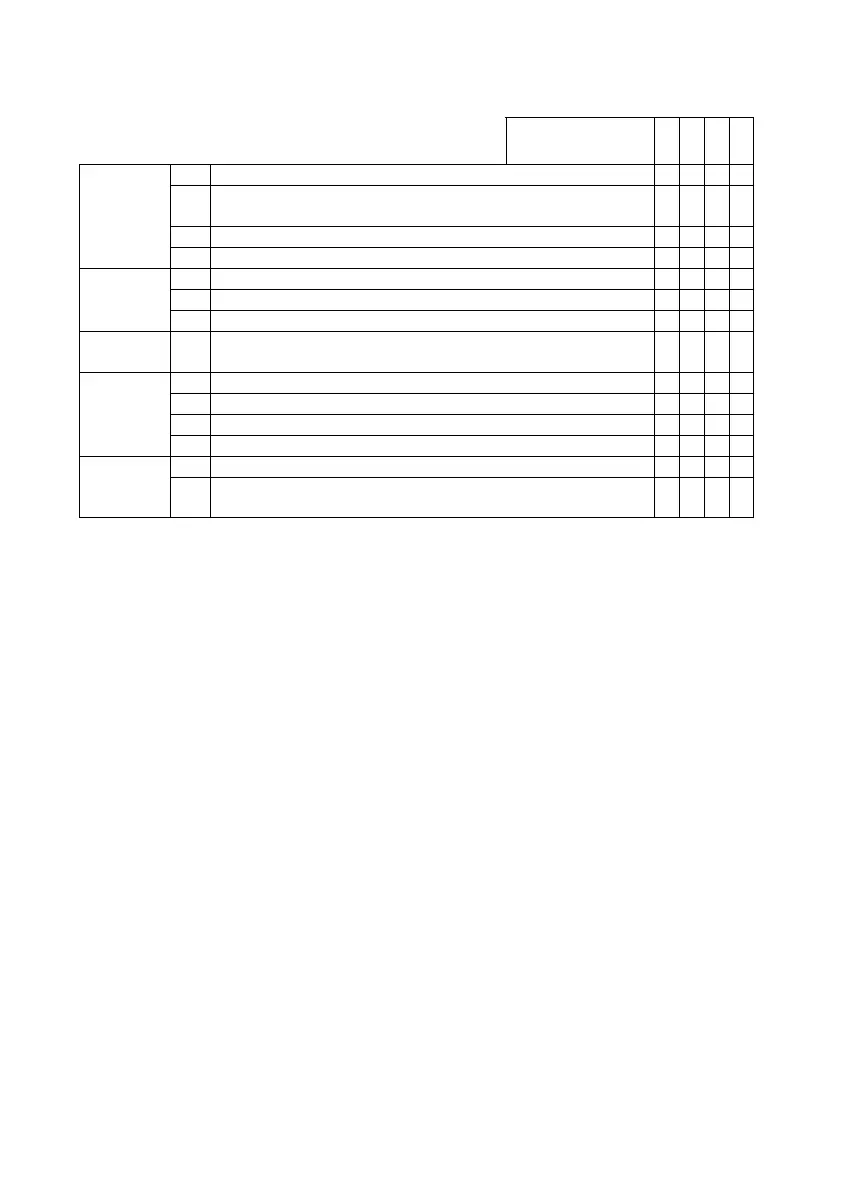

Maintenance intervals

standard = t WMMM

cold store = k 13612

Battery 9.1 Check acid density, acid level and cell voltage lt

9.2 Check the terminals for secure attachment and apply grea-

se

lt

9.3 Clean battery connections, check for tight seat lt

9.4 Check the battery cables for damage, renew, if necessary t

Lifting

device

10.1 Performance, wear and adjustment check t

10.2 Perform sight check of rollers, sliding elements, and stops lt

10.3 Check fork tines and fork carrier for wear and damage lt

Lubricati-

on

11.1 Grease the vehicle in accordance with the lubrication sche-

dule

lt

General

measure-

ments

12.1 Check the electrical system for a grounding fault t

12.2 Check the driving speed and braking distance t

12.3 Check the lifting and lowering speed t

12.4 Check safety and shutdown devices t

Demon-

stration

13.1 Perform a trial run under a nominal load t

13.2 Upon completion of servicing operations, demonstrate the

vehicle to the person responsible

lt

F 5

0803.GB

a) Wheel bolts to be first checked for tightness after approx. 100 operating hours; tighten, if

necessary.

b) Hydraulic connections to be first checked for leakage after approx. 100 operating hours;

tighten, if necessary.

c) First change after 500 operating hours.

A

The maintenance intervals refer to normal service conditions. In case of aggravated

conditions, the intervals must be reduced as required.

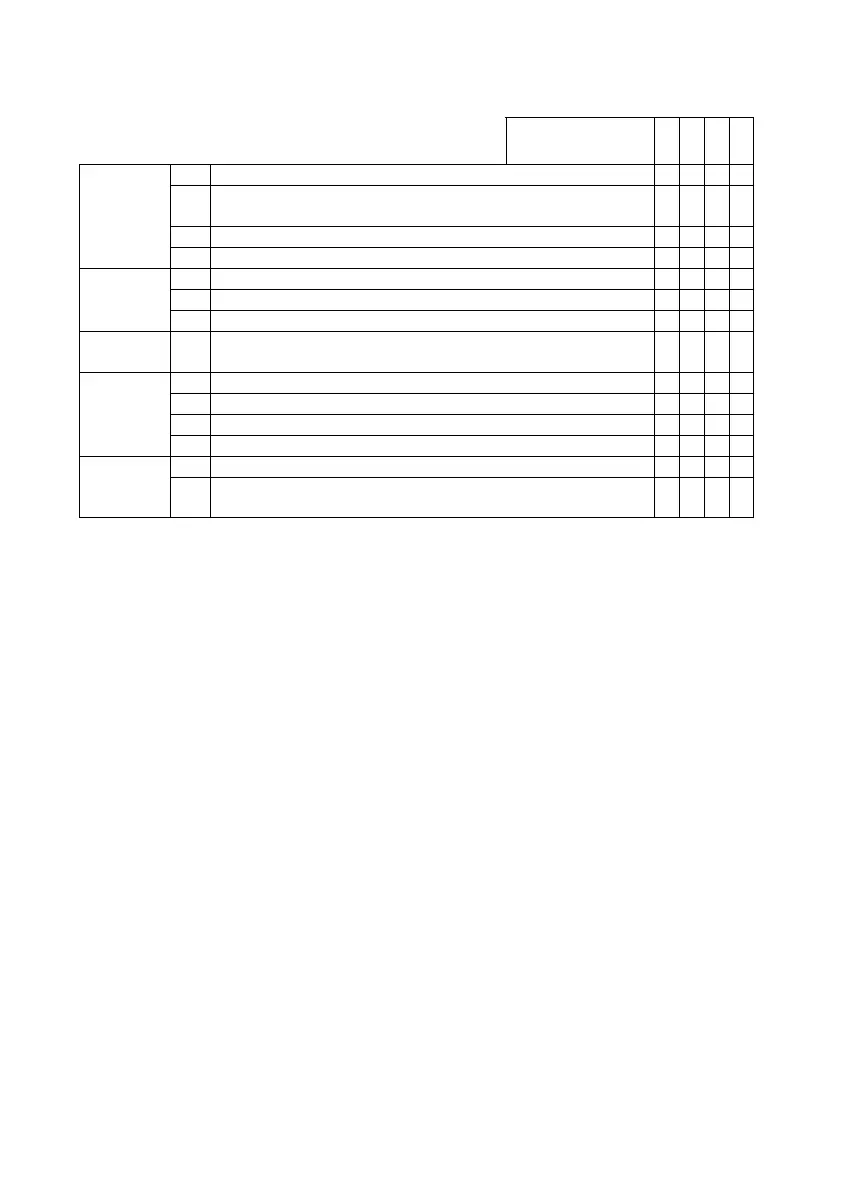

Maintenance intervals

standard = t WMMM

cold store = k 13612

Battery 9.1 Check acid density, acid level and cell voltage lt

9.2 Check the terminals for secure attachment and apply grea-

se

lt

9.3 Clean battery connections, check for tight seat lt

9.4 Check the battery cables for damage, renew, if necessary t

Lifting

device

10.1 Performance, wear and adjustment check t

10.2 Perform sight check of rollers, sliding elements, and stops lt

10.3 Check fork tines and fork carrier for wear and damage lt

Lubricati-

on

11.1 Grease the vehicle in accordance with the lubrication sche-

dule

lt

General

measure-

ments

12.1 Check the electrical system for a grounding fault t

12.2 Check the driving speed and braking distance t

12.3 Check the lifting and lowering speed t

12.4 Check safety and shutdown devices t

Demon-

stration

13.1 Perform a trial run under a nominal load t

13.2 Upon completion of servicing operations, demonstrate the

vehicle to the person responsible

lt

Loading...

Loading...