0602.GB

E 28

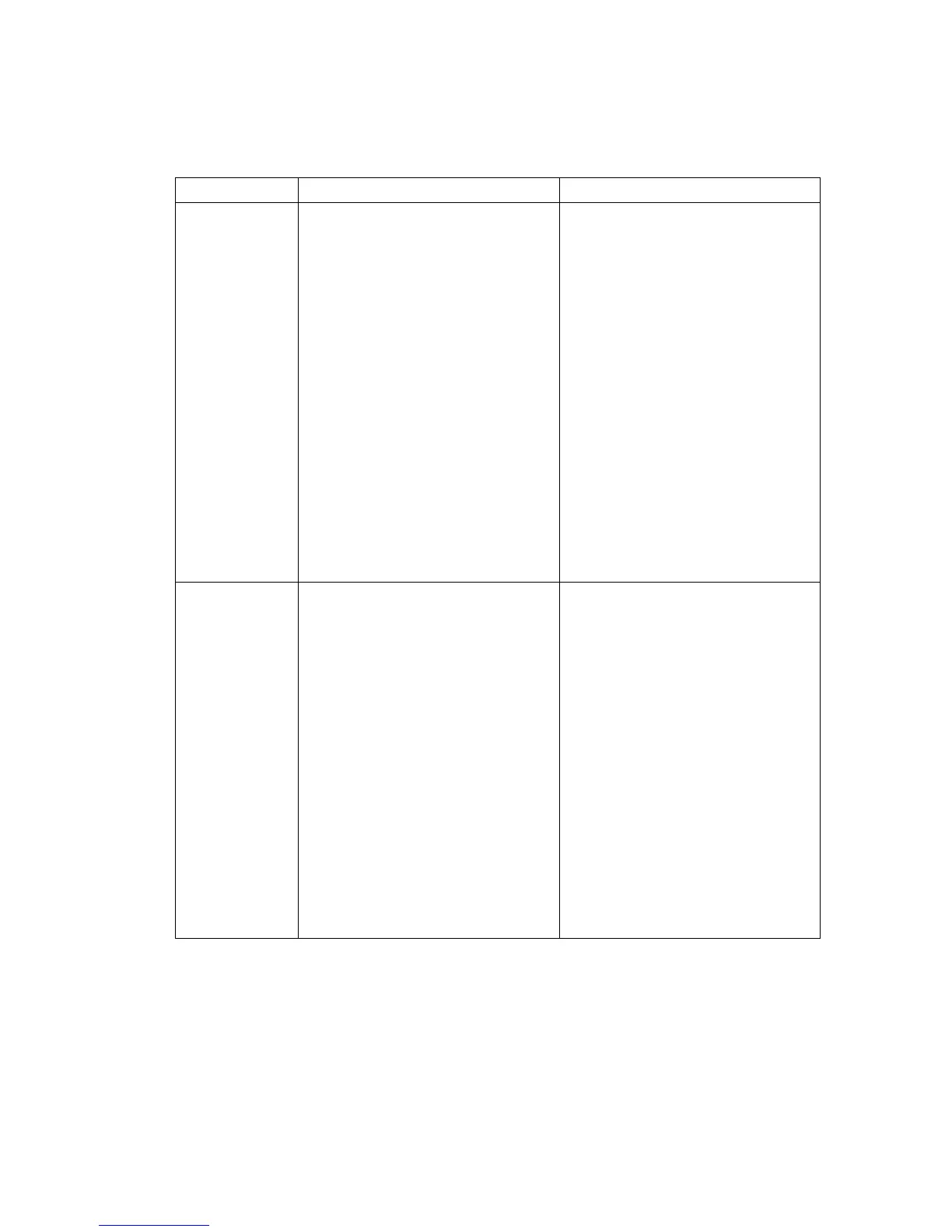

8 Fault location

This chapter helps the operator to locate and fix simple malfunctions or the results of

operating errors him- or herself. The order of the work stated in the table must be ob-

served for fault location.

A

If it is not possible to rectify the fault by performing the indicated “remedial actions”,

please contact the Customer Service, as more intricate faults can only be rectified by

specially trained and qualified service personnel.

Fault Possible cause Remedy

Truck does not

move

– Battery connector

not connected

– Check the battery connector

and reconnect it, if necessary

– Master switch (EMERGENCY

STOP) pressed

– Release master switch (EMER-

GENCY STOP)

– Key switch in position “0”. – Set the key switch to position

“I”.

– No driver on folded-out plat-

form, lifting and travel function

not active

– Stand on folded-out platform

– Battery voltage too low – Check the charging status of

the battery and recharge, if ne-

cessary

– Control shaft not swivelled into

driving range (F)

– Swivel control shaft into driving

range (F)

– Faulty fuse – Check fuses F1 and 1F1

– Truck battery charger is con-

nected

– Disconnect the truck battery

charger from the mains

Load cannot

be lifted

– Truck not operative. – Perform all troubleshooting

measures that are mentioned

under “truck does not drive”

– refer to switching matrix / safety

switching height

– No driver on folded-out plat-

form, lifting and travel function

not active

– Stand on folded-out platform

– Hydraulic oil level too low – Check hydraulic oil level

– Faulty fuse – Check fuse 2F1

– load too high – Pay attention to the maximum

bearing capacity (see identifi-

cation label)

– Discharge monitor is triggered

(STOP icon)

– Check the charging status of

the battery and recharge, if

necessary

0602.GB

E 28

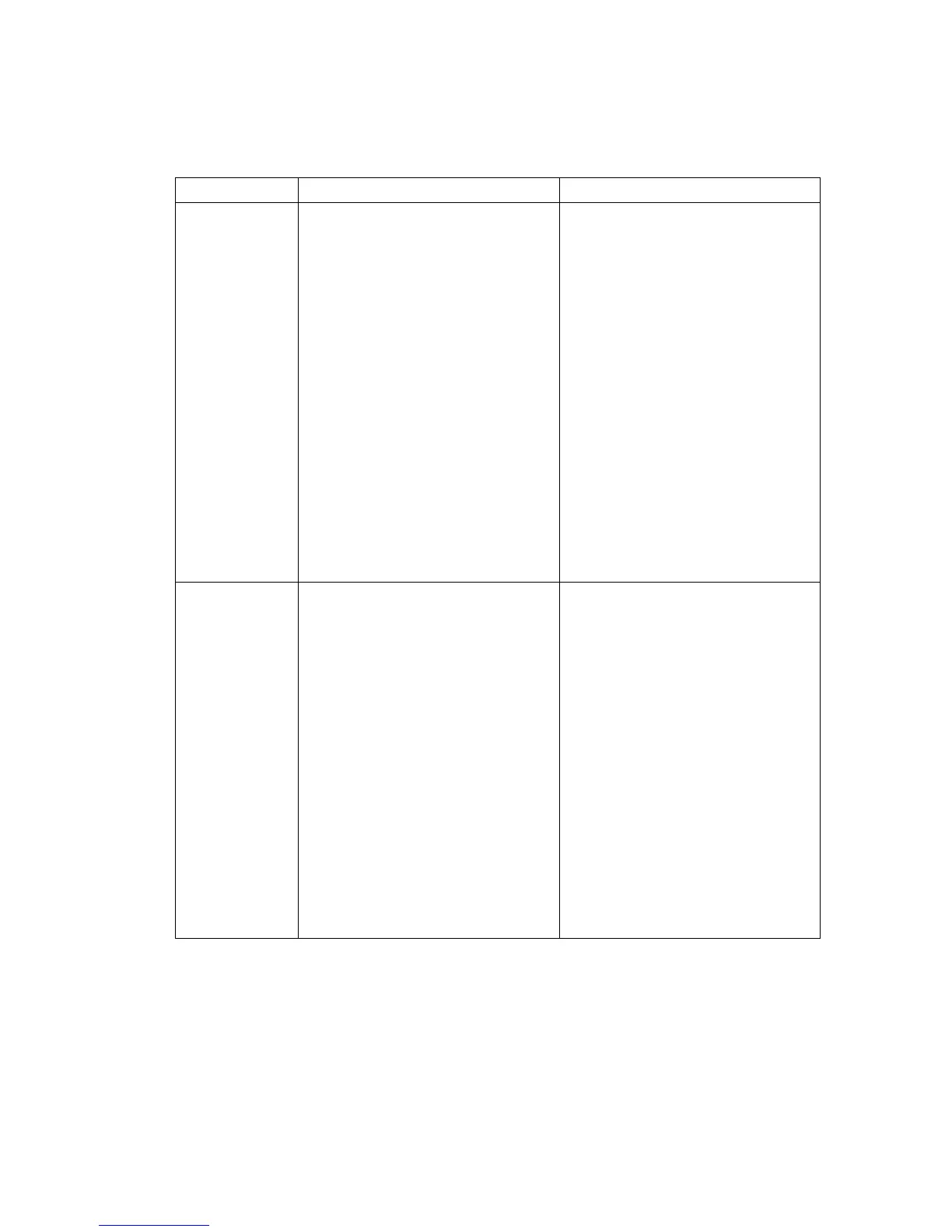

8 Fault location

This chapter helps the operator to locate and fix simple malfunctions or the results of

operating errors him- or herself. The order of the work stated in the table must be ob-

served for fault location.

A

If it is not possible to rectify the fault by performing the indicated “remedial actions”,

please contact the Customer Service, as more intricate faults can only be rectified by

specially trained and qualified service personnel.

Fault Possible cause Remedy

Truck does not

move

– Battery connector

not connected

– Check the battery connector

and reconnect it, if necessary

– Master switch (EMERGENCY

STOP) pressed

– Release master switch (EMER-

GENCY STOP)

– Key switch in position “0”. – Set the key switch to position

“I”.

– No driver on folded-out plat-

form, lifting and travel function

not active

– Stand on folded-out platform

– Battery voltage too low – Check the charging status of

the battery and recharge, if ne-

cessary

– Control shaft not swivelled into

driving range (F)

– Swivel control shaft into driving

range (F)

– Faulty fuse – Check fuses F1 and 1F1

– Truck battery charger is con-

nected

– Disconnect the truck battery

charger from the mains

Load cannot

be lifted

– Truck not operative. – Perform all troubleshooting

measures that are mentioned

under “truck does not drive”

– refer to switching matrix / safety

switching height

– No driver on folded-out plat-

form, lifting and travel function

not active

– Stand on folded-out platform

– Hydraulic oil level too low – Check hydraulic oil level

– Faulty fuse – Check fuse 2F1

– load too high – Pay attention to the maximum

bearing capacity (see identifi-

cation label)

– Discharge monitor is triggered

(STOP icon)

– Check the charging status of

the battery and recharge, if

necessary

Loading...

Loading...