1001.GB

F 4

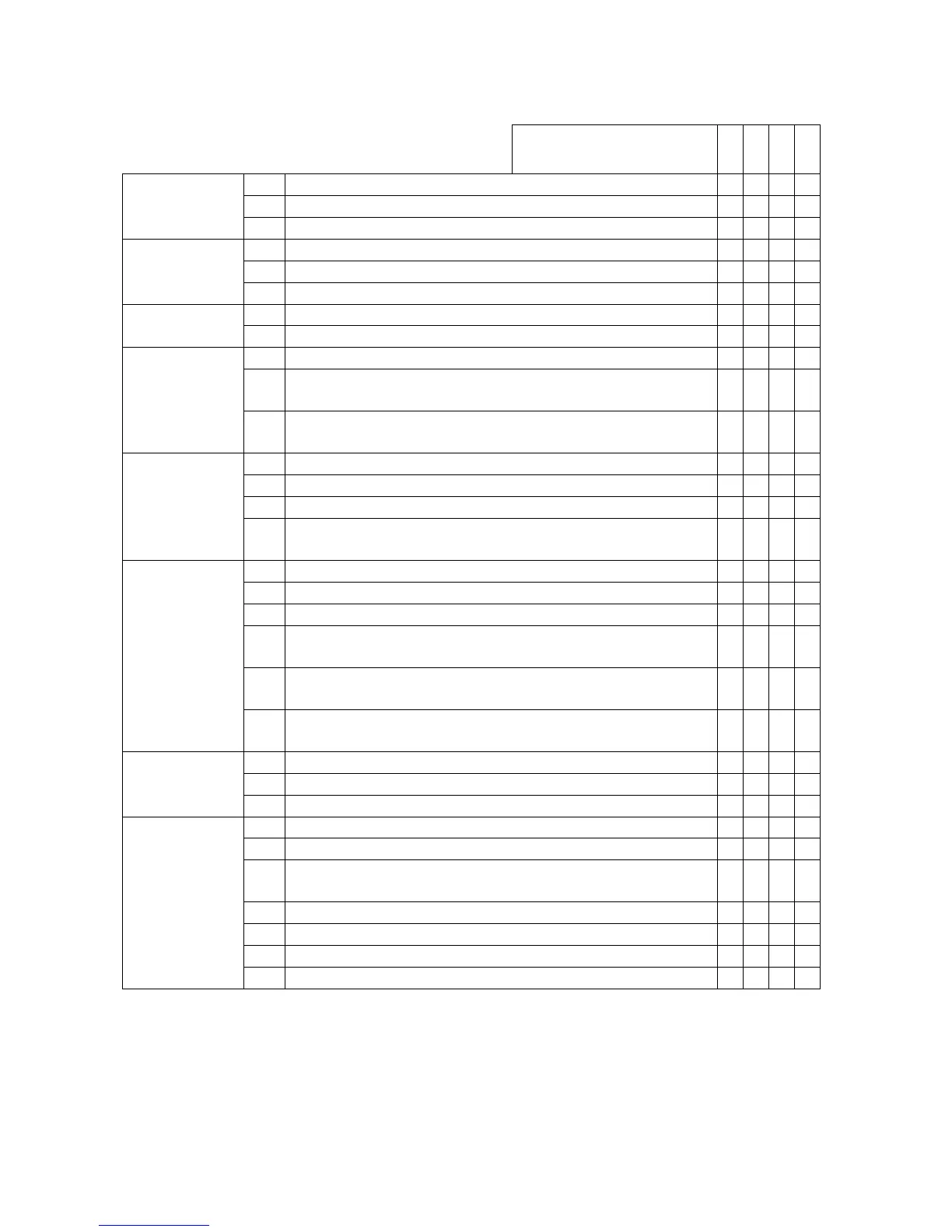

4 Maintenance checklist

Maintenance intervals

Standard = t WMMM

Cold-storage depot = k 13612

Chassis/

Design:

1.1 Check all load bearing elements for damage t

1.2 Check all bolted connections t

1.3 Check platform for correct functioning and damage t

Drive unit: 2.1 Check the transmission for noises and leakage t

2.2 Check the transmission oil level t

2.3 Change the transmission oil lt

Wheels: 3.1 Check for wear and damage t

3.2 Check the wheel bearings for correct fasteninga) lt

Steering: 4.1 Check the steering wheel play t

4.2 Check the steering chain and chain sprocket for wear,

adjust and grease

lt

4.3 Check mechanical parts of steering column and grease,

if required

t

Brake

system:

5.1 Performance and adjustment check t

5.2 Check the brake linings for wear t

5.3 Check the brake linkage; adjust and grease, if necessary lt

5.4 Gas pressure spring (tiller shaft) to reset function,

check for tightness and damages

t

Hoist frame: 6.1 Visual inspection of rollers lt

6.2 Check fork tines and fork carrier for wear and damage lt

6.3 Check secure attachment of hoist frame t

6.4 Check lift chains and chain guide for wear, adjust and

grease them.

t

6.5 Check the lateral clearance of the mast profiles and

whether they are parallel to each other

t

6.6 Check safety devices for proper attachment

and damages

lt

Lifting de-

vice:

7.1 Check function, wear and tear and adjustment t

7.2 Visual check of rollers, slide pieces and stops lt

7.3 Check fork tines and fork carrier for wear and damage lt

Hydr. system: 8.1 Check function kt

8.2 Check all connections for leakage and damage b) kt

8.3 Check hydraulic cylinders for leakage, damage and

secure attachment

kt

8.4 Check the oil level kt

8.5 Change hydraulic oil c) kt

8.6 Change filter t

8.7 Check the pressure relief valves for correct functioning kt

1001.GB

F 4

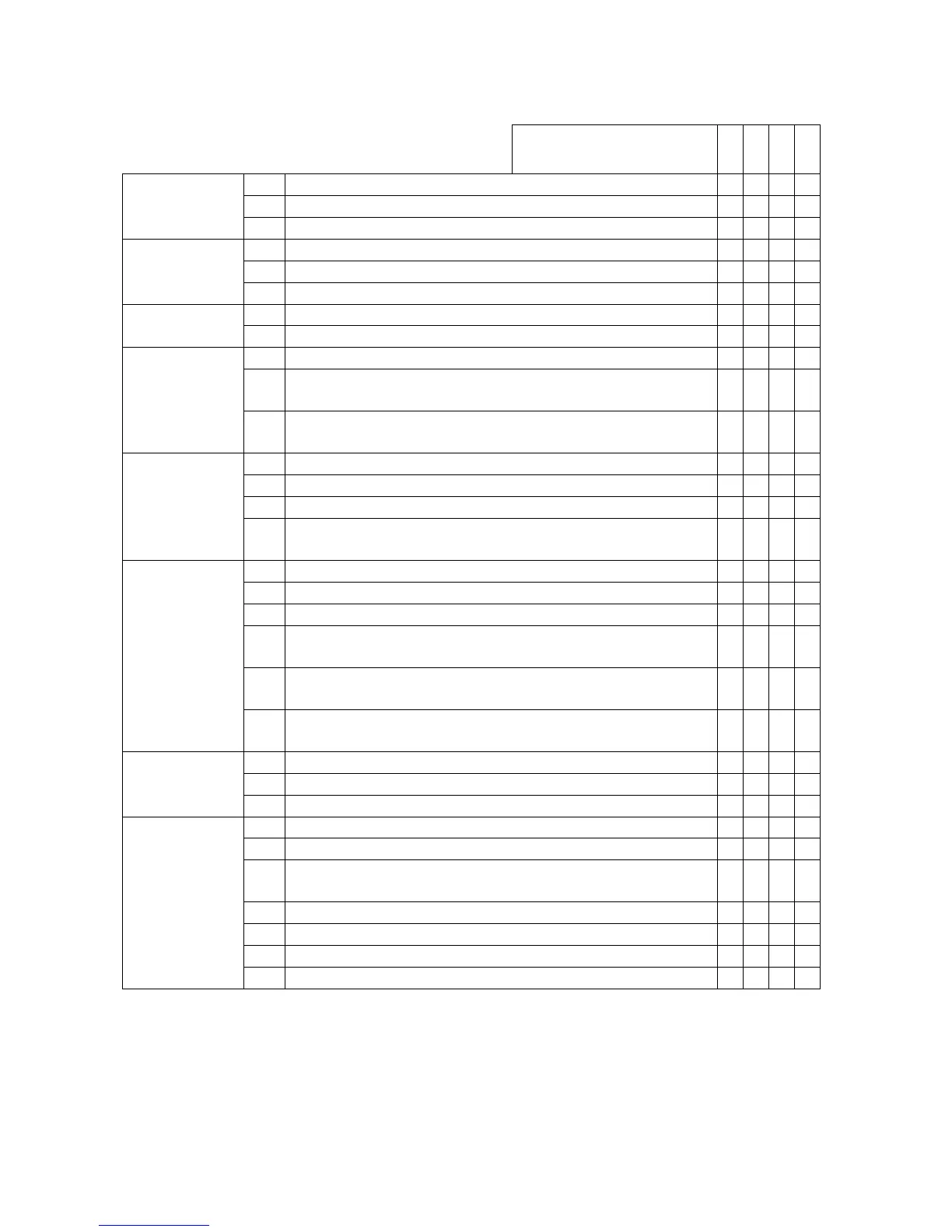

4 Maintenance checklist

Maintenance intervals

Standard = t WMMM

Cold-storage depot = k 13612

Chassis/

Design:

1.1 Check all load bearing elements for damage t

1.2 Check all bolted connections t

1.3 Check platform for correct functioning and damage t

Drive unit: 2.1 Check the transmission for noises and leakage t

2.2 Check the transmission oil level t

2.3 Change the transmission oil lt

Wheels: 3.1 Check for wear and damage t

3.2 Check the wheel bearings for correct fasteninga) lt

Steering: 4.1 Check the steering wheel play t

4.2 Check the steering chain and chain sprocket for wear,

adjust and grease

lt

4.3 Check mechanical parts of steering column and grease,

if required

t

Brake

system:

5.1 Performance and adjustment check t

5.2 Check the brake linings for wear t

5.3 Check the brake linkage; adjust and grease, if necessary lt

5.4 Gas pressure spring (tiller shaft) to reset function,

check for tightness and damages

t

Hoist frame: 6.1 Visual inspection of rollers lt

6.2 Check fork tines and fork carrier for wear and damage lt

6.3 Check secure attachment of hoist frame t

6.4 Check lift chains and chain guide for wear, adjust and

grease them.

t

6.5 Check the lateral clearance of the mast profiles and

whether they are parallel to each other

t

6.6 Check safety devices for proper attachment

and damages

lt

Lifting de-

vice:

7.1 Check function, wear and tear and adjustment t

7.2 Visual check of rollers, slide pieces and stops lt

7.3 Check fork tines and fork carrier for wear and damage lt

Hydr. system: 8.1 Check function kt

8.2 Check all connections for leakage and damage b) kt

8.3 Check hydraulic cylinders for leakage, damage and

secure attachment

kt

8.4 Check the oil level kt

8.5 Change hydraulic oil c) kt

8.6 Change filter t

8.7 Check the pressure relief valves for correct functioning kt

Loading...

Loading...