All the cooling oil has run out of the separator cartridge 1–2 minutes after shutting down. A cooling

oil receptacle is not needed.

Material Spare parts

Cleaning cloths

Precondition The power supply disconnecting device is switched off,

The device is locked off,

A check has been made that no voltage is present.

The machine is completely vented at atmospheric pressure, the pressure gauge on the oil separa‐

tor tank reads 0 psig.

There is risk of burns from hot components and oil!

➤ Wear long-sleeved clothing and protective gloves.

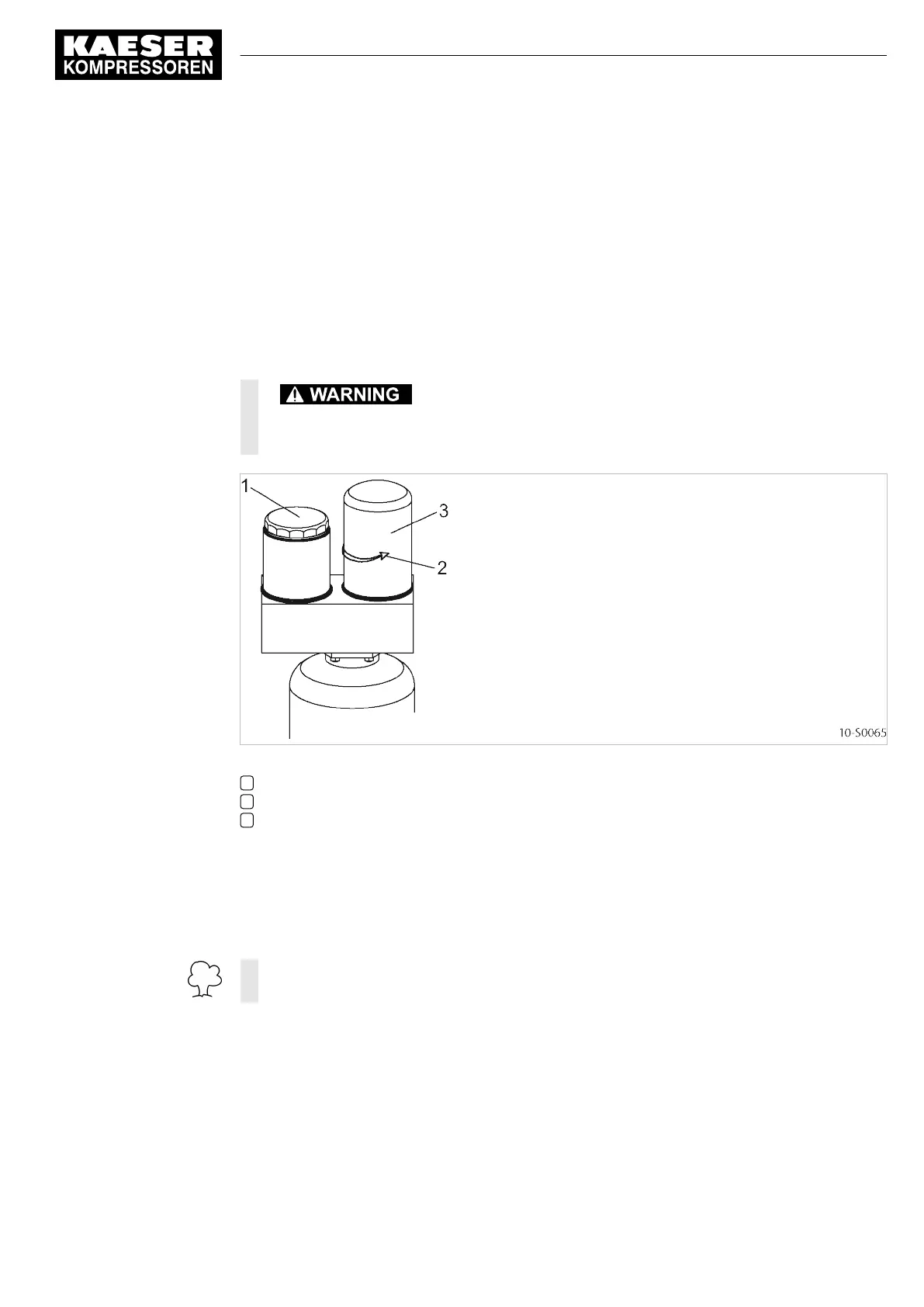

Fig. 27 Changing the oil separator cartridge

1 Oil filter

2 Direction to unscrew

3 Oil separator cartridge

Changing the oil separator cartridge

1. Unscrew the oil separator cartridge counterclockwise and wipe off any drops of oil.

2. Lightly oil the new filter's gasket.

3. Turn the oil filter clockwise by hand to tighten.

➤ Dispose of parts and material contaminated with cooling oil according to environment

protection regulations.

Starting the machine and carrying out a trial run

1. Replace the enclosure cover.

2. Open the user's shut-off valve between the machine and the air distribution network.

3. Switch on the power supply and reset the maintenance interval counter.

4. Start the machine and run it for 10 minutes, then stop it and visually check for leaks.

10 Maintenance

10.13 Changing the oil separator cartridge

9_6917 34 USE

Operator Manual Screw Compressor

AIRTOWER 3C–7.5C Tri-Voltage

73

Loading...

Loading...