9Kamstrup A/S • 55122412_A1_GB_2019-03

MULTICAL® 803 & ULTRAFLOW®

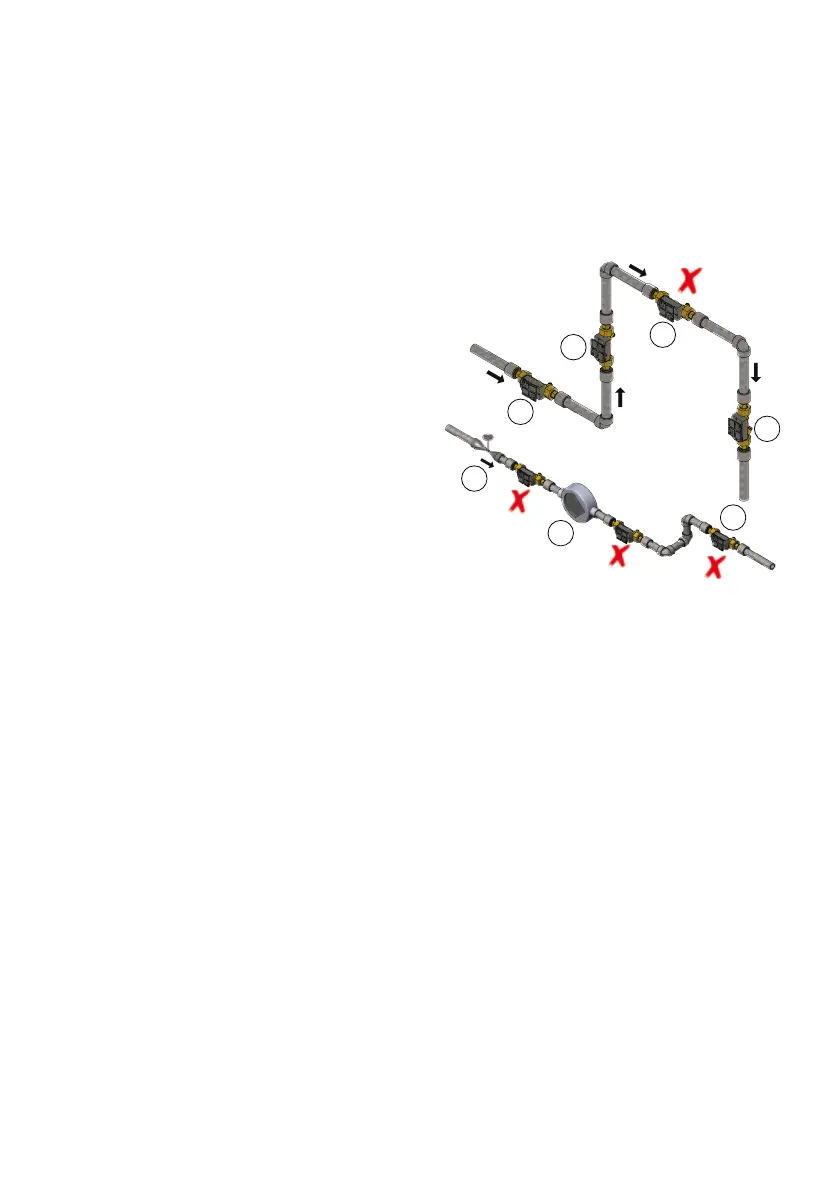

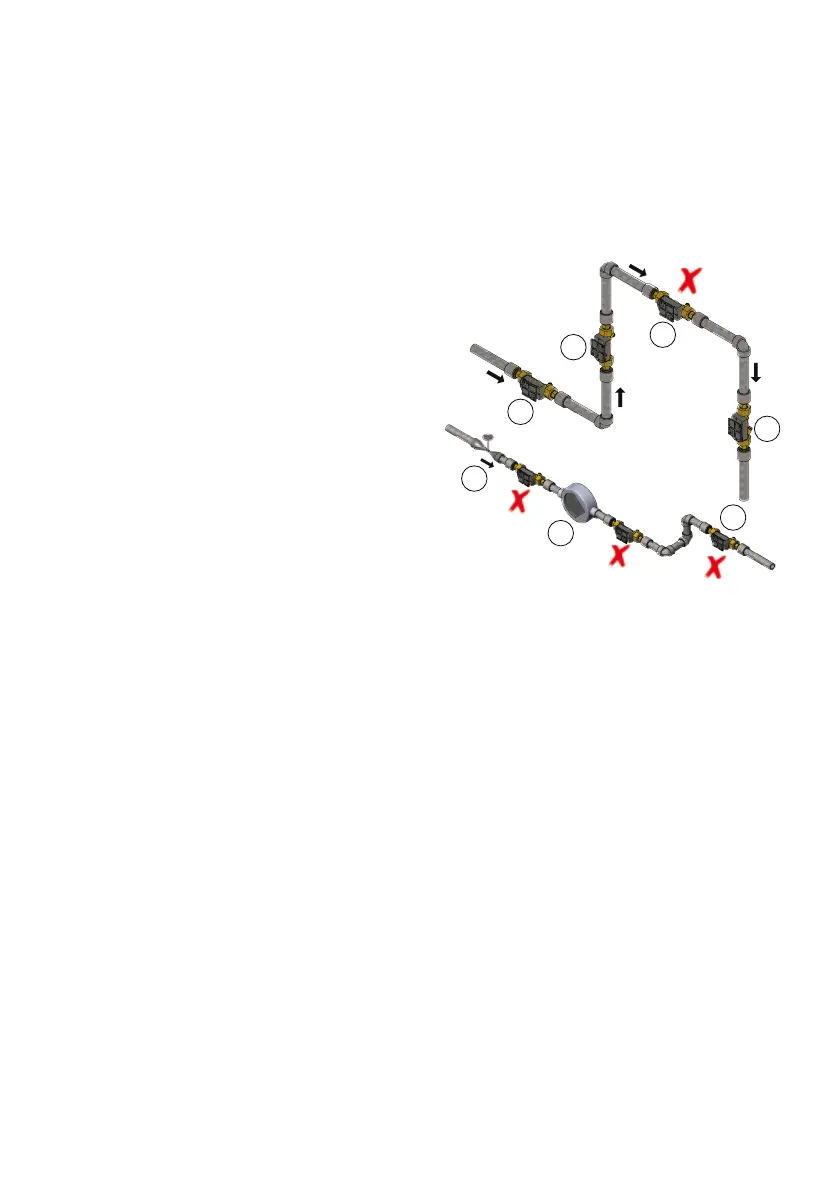

3.4 Flow sensor position

Kamstrup flow sensors require neither straight inlet nor straight outlet to meet the Measuring

Instruments Directive (MID) 2014/32/EU, OIML R75:2002 and EN 1434:2015. A straight inlet section

will only be necessary in case of heavy flow disturbances before the meter. It is recommended to

follow the guidelines of CEN CR 13582.

A Recommended position.

B Recommended position.

C Unacceptable position due to risk of air

build-up.

D Acceptable position in closed systems.

E Ought not to be placed immediately after

a valve, with the exception of block valves

(ball valve type) which must be fully open

when not used for blocking.

F Ought not to be placed immediately before

or after a pump.

G Ought not to be placed immediately after a

double bend in two planes.

A

B

C

D

E

F

G

In order to avoid cavitation, the back pressure at the flow sensor (the pressure at the flow sensor

outlet) must be minimum 1.5 bar at q

p

(nominal flow) and minimum 2.5 bar at q

s

(maximum flow).

This applies to temperatures up to approx. 80 °C. The flow sensor must not be exposed to pressure

lower than the ambient pressure (vacuum).

Loading...

Loading...