Deutsch 5.962-786.0 Rev. 05 (06/13) 53

For each valve, the length of a straight pipe with the

same flow resistance is indicated in the following ta-

ble.

Final example:

The pressure loss in a plant with HD 1200 l/h and the

following components is calculated:

Calculation:

100 m = 7.0 bar pressure loss

8.5 m= 0.6 bar pressure loss

108.5 m = 7.60 bar pressure loss

The following table indicates the pressure loss in a

hose line of 10 m length.

Table 5

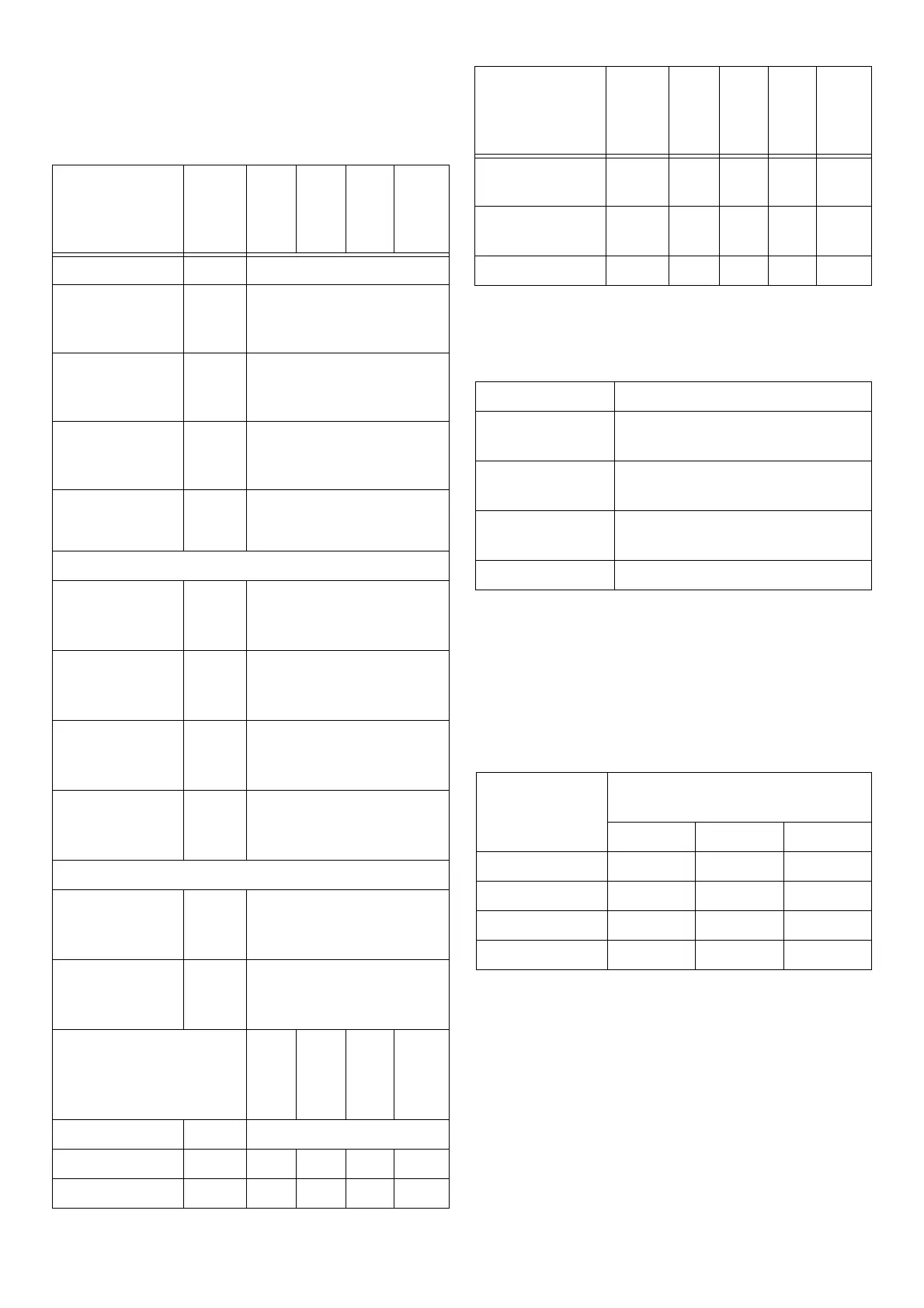

6.4.3 Pressure loss in valves

Valve DN1

0 -

DN1

5

DN2

0 -

DN2

5

DN3

2 -

DN4

0

DN

50

and

more

Bushing 0

Ellbow 90°

r/d = 1.5

0,5

Ellbow 90°

r/d = 2.5

0,3

Double ellbow

wide

1

Double ellbow

narrow

2

T-piece, 90° angle

Tee branch

separation (ex-

traction point)

1,5

T-diameter in-

side

separation

0

T counter direc-

tion

separation

1,3

T counter direc-

tion

merging

3

Tee, streamlined

Tee branch

separation (ex-

traction point)

0,5

T-diameter in-

side

separation

0

DN1

0 -

DN1

5

DN2

0 -

DN2

5

DN3

2 -

DN4

0

DN

50

and

more

Storage 2,5

Knee 2 1,5 1 1

Locking slide 1 0,5 0,3 0,3

Inclined-seat

valve

3,5 3 2,5 2

Full stream

valve

1,5 1 0,5 0,5

DIN stop valve 10 7 5 4

Component corresponds to flow resistance

Pipe DN12,

100 m

100 m

5 extraction

points

2.5 m

3 knee connec-

tions

6 m

HD 1200 l/h Sum 108.5 m

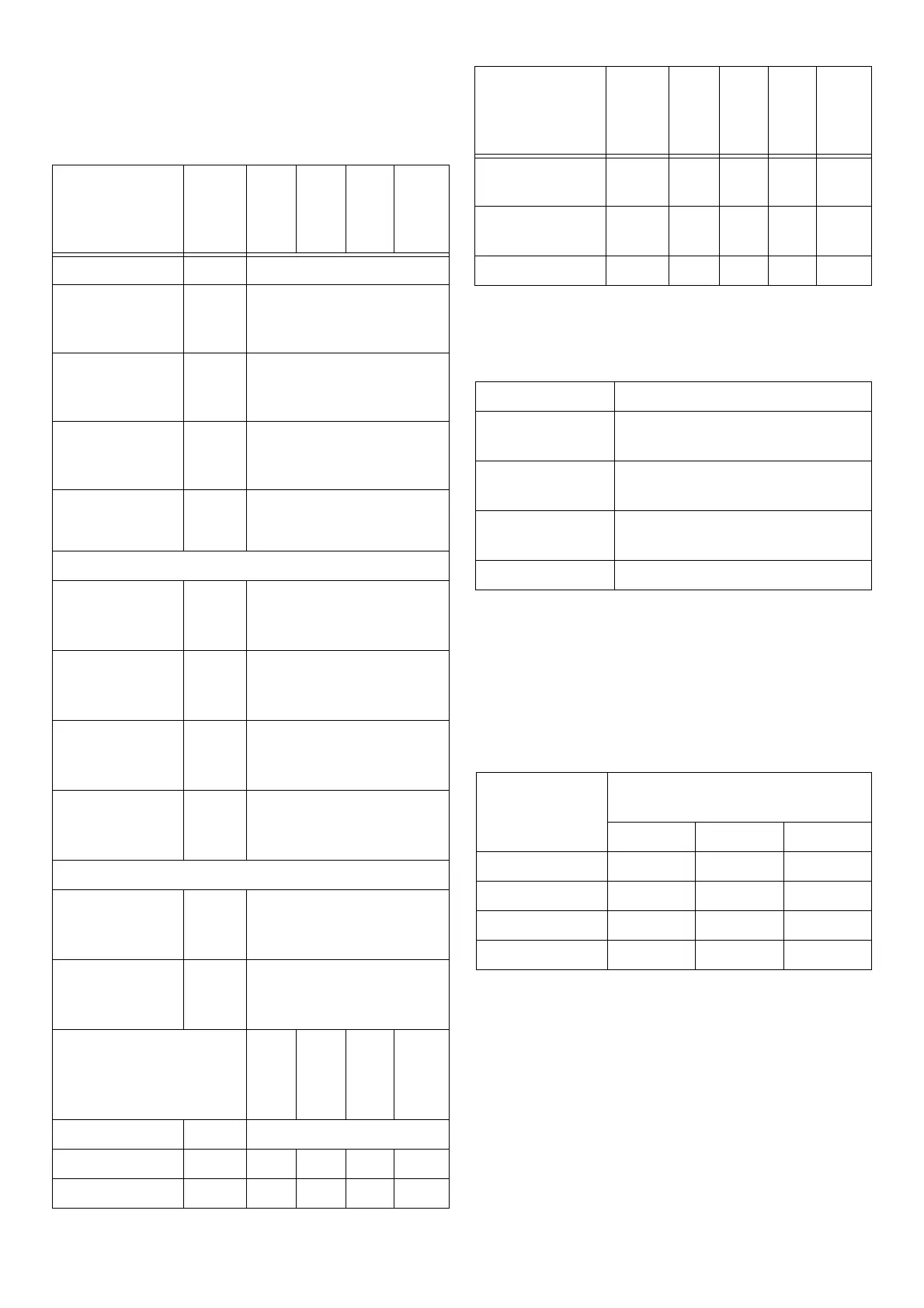

6.4.4 Pressure loss in high-pressure hose lines

Pressure loss

with 10 m hose

[bar]

Water volume [l/h]

750 1000 3000

DN 8 2 4,5 -

DN 10 1,5 2,1 12,5

DN 13 0,2 0,45 3,2

DN 20 - - 0,4

Valve DN1

0 -

DN1

5

DN2

0 -

DN2

5

DN3

2 -

DN4

0

DN

50

and

more

Loading...

Loading...