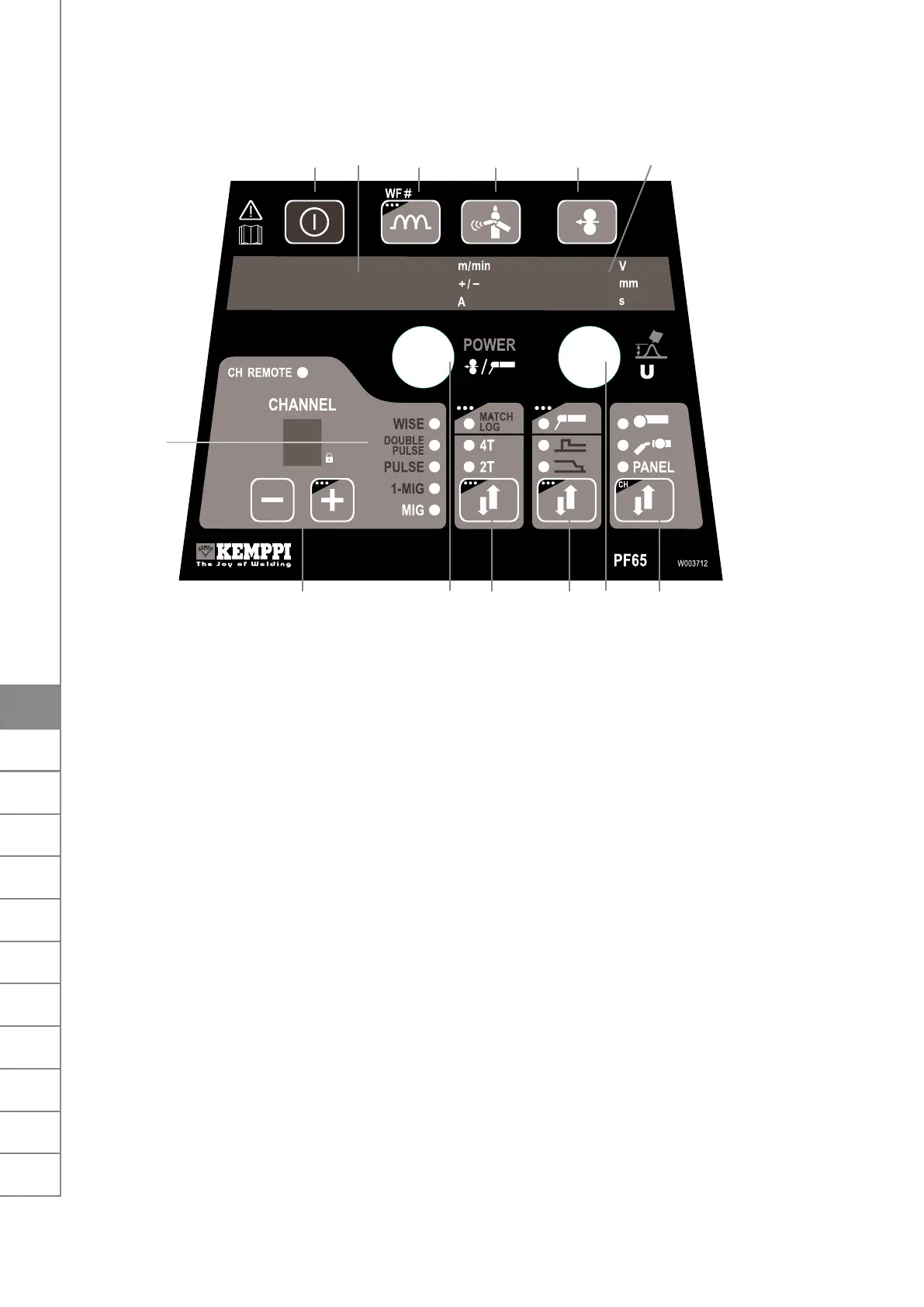

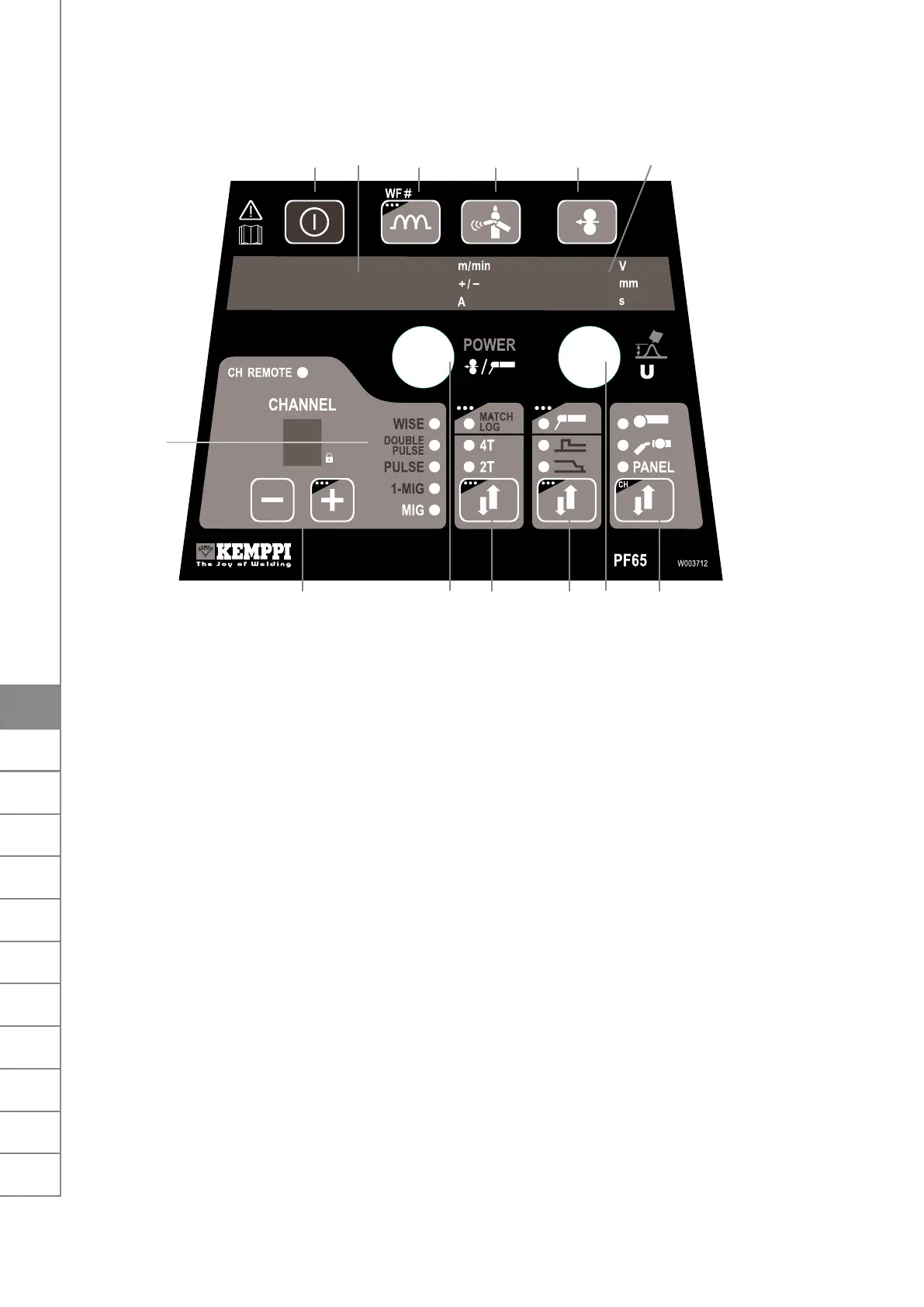

PF65 PANEL OVERVIEW5.12

9. 13.10.11. 12.7.

8.

1. 4.3. 5.

2. 6.

Main switch (long press)1.

a) Wire feed speed/welding current display 2.

b) Display of selected adjustable parameter

a) Activation of MIG welding dynamics / Arc Force adjustment 3.

b) Selection of Wire Feeder (= paralleled wire feeders)

Gas purge 4.

Wire inch 5.

a) Display of welding voltage /plate thickness /timer settings 6.

b) Display of selected adjustable parameter

Selection of MIG gun trigger function: 2T/4T/MATCHLOG long press *)7.

Display of welding process: MIG, 1-MIG, PULSE, DOUBLE PULSE, WISE *)8.

a) Selection of additional MIG functions 9.

b) Activation of MMA welding process (long press*)

a) Adjustment of wire feed speed 10.

b) Adjustment of welding power (Synergic 1-MIG and PULSE)

c) Adjustment of electrode welding (MMA) current *)

d) Adjustment of additional parameters when selected (ie Wire inch, Gas Test)

Memory channels 0-9, programming through P65 panel on the power source, panel lock 11.

(long press on +)

a) Adjustment of welding voltage 12.

b) Adjustment of length of welding arc (Synergic 1-MIG and PULSE)

c) Adjustment of additional parameters when selected (ie MIG Dynamics)

Panel control/remote control unit selection, channel remote control (long press)13.

*) Not included on standard delivery, see chapter 6: Ordering numbers

Automatic Weld Data display:

Last recorded welding values are displayed post welding. See power source panel P65.Select

MENU and then Weld Data.

20

FastMig MXF65, 67 / © Kemppi Oy / 0920

I

Loading...

Loading...