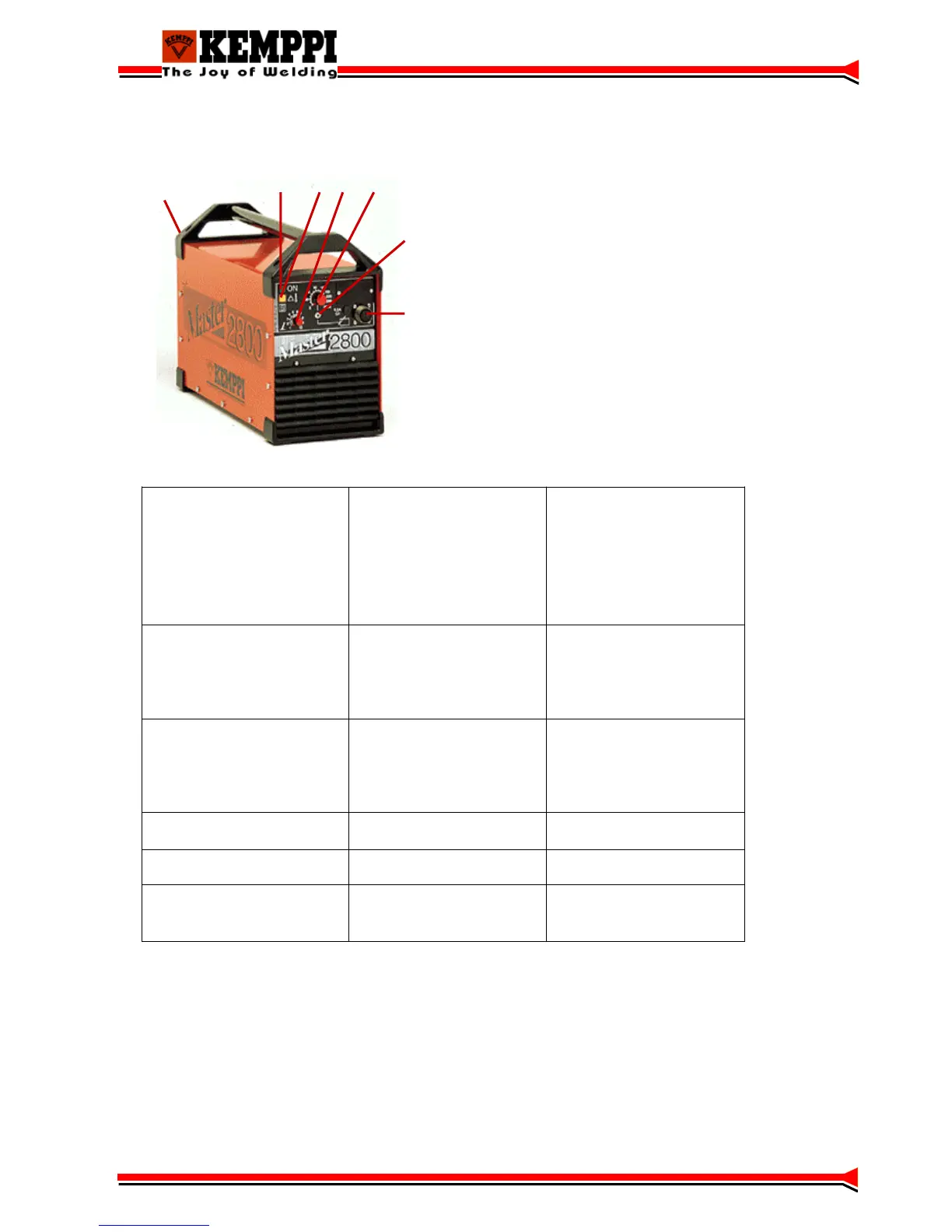

Master 2800 and 3500

1 Main switch S001 and welding current connectors

2 I/0-signal lamp

3 Overheat protection signal lamp

4 Dynamics adjustment

5 Current adjustment potentiometer

6 local / remote control

7 Remote controller connector

1

234

6

5

7

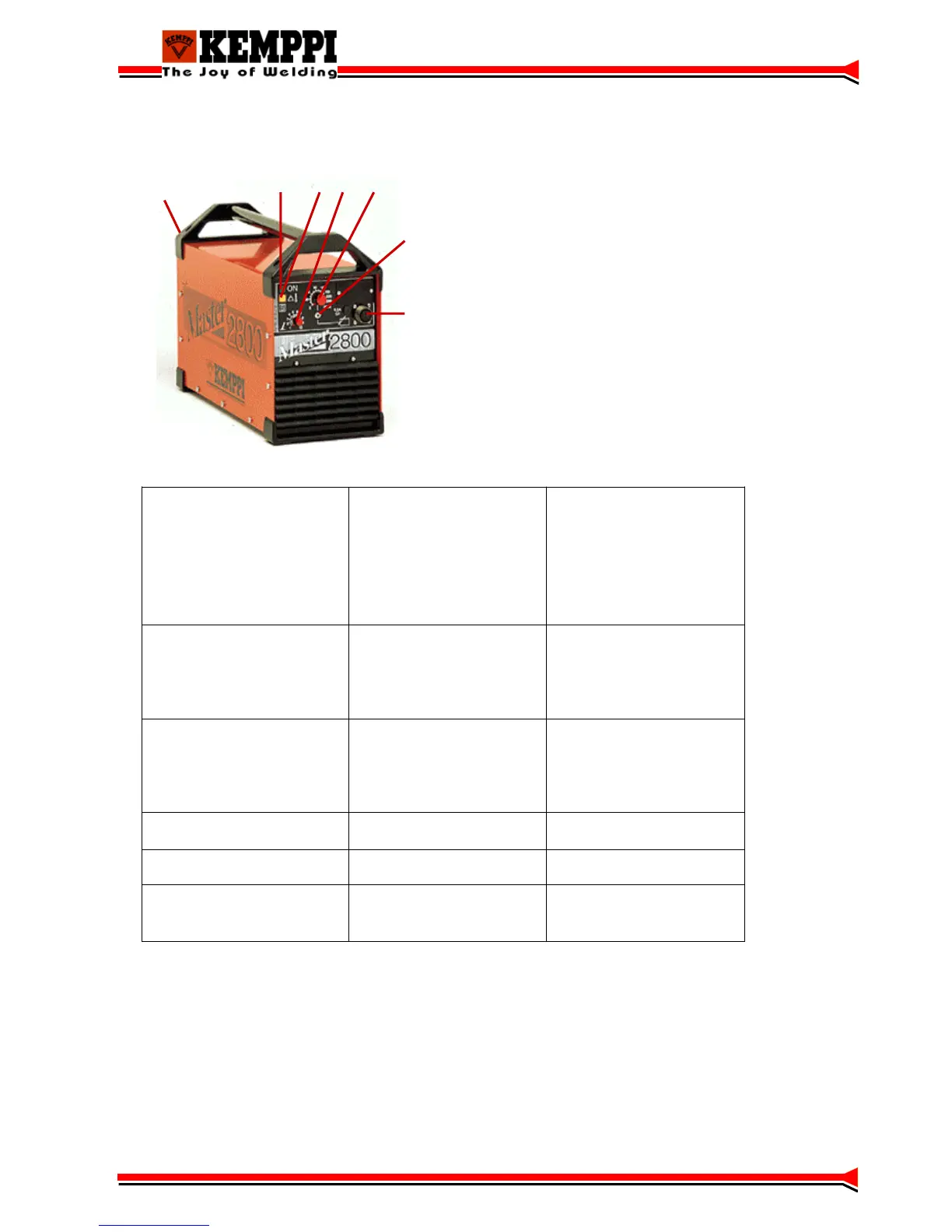

Supply voltage 3

∼

,50/60 Hz

Connection power 35% ED

60% ED

100% ED

Supply cable/ fuses

380V –10%….415V +6%

280 A / 11,5 kVA

213 A / 8,5 kVA

165 A / 6,0 kVA

4 x 1,5S / 10 A slow

380V –10%….415V +6%

350 A / 15,0 kVA

267 A / 11,0 kVA

207 A / 8,0 kVA

4 x 2,5S / 16 A slow

Welding current range MMA

(TIG

Suitable electrode sizes

Welding power adjustment

15 A / 20,5 V…280 A / 31,2 V

5 A / 10,2 V…280 A / 21,2 V)

∅

1,5…n. 5,0 mm

stepless

15 A / 20,5 V…350 A / 34,0 V

5 A / 10,2 V…350 A / 24,0 V)

∅

1,5…n. 6,0 mm

stepless

OCV

Efficiency

Idling power

Approx. 75 V

83% (280 A/ 31,2 V)

approx. 25 W

approx. 75 V

83% (350 A/ 34,0 V)

approx. 25 W

Degree of protection / Casing

class

IP 23 IP 23

Weight 22 kg (TIG, 27 kg) 25 kg (TIG, 30 kg)

Auxiliary devices Remote controllers

C 100C, C 100D, C100T,

MSD 1

Remote controllers

C 100C, C 100D, C100T,

MSD 1

6

Loading...

Loading...