TEFC_A-BA-e-2110 19

• Prepare the required adjustment weight, see chapter 1.

Whenever possible, adjust using the adjustment weight with the weight simi-

lar to the maximum load of the scale (the adjustment weight is recommend-

ed, see chapter 1). The adjustment may also be carried out using weights

with other nominal values or tolerance classes, but this is not optimal from

the measurement technique perspective. The adjustment weight precision

must correspond to the interval [d] of the scale, though preferably it should be

a bit higher. For information concerning reference weights, see online at:

http://www.kern-sohn.com

•

Ensure stable environmental conditions. The heating time is required for the

stabilization (see chapter 1).

• Ensure there are no objects on the scale plate.

What to do:

Switch the scale off.

With TOL pressed, switch the scale on using ON/OFF. During the autotest, press

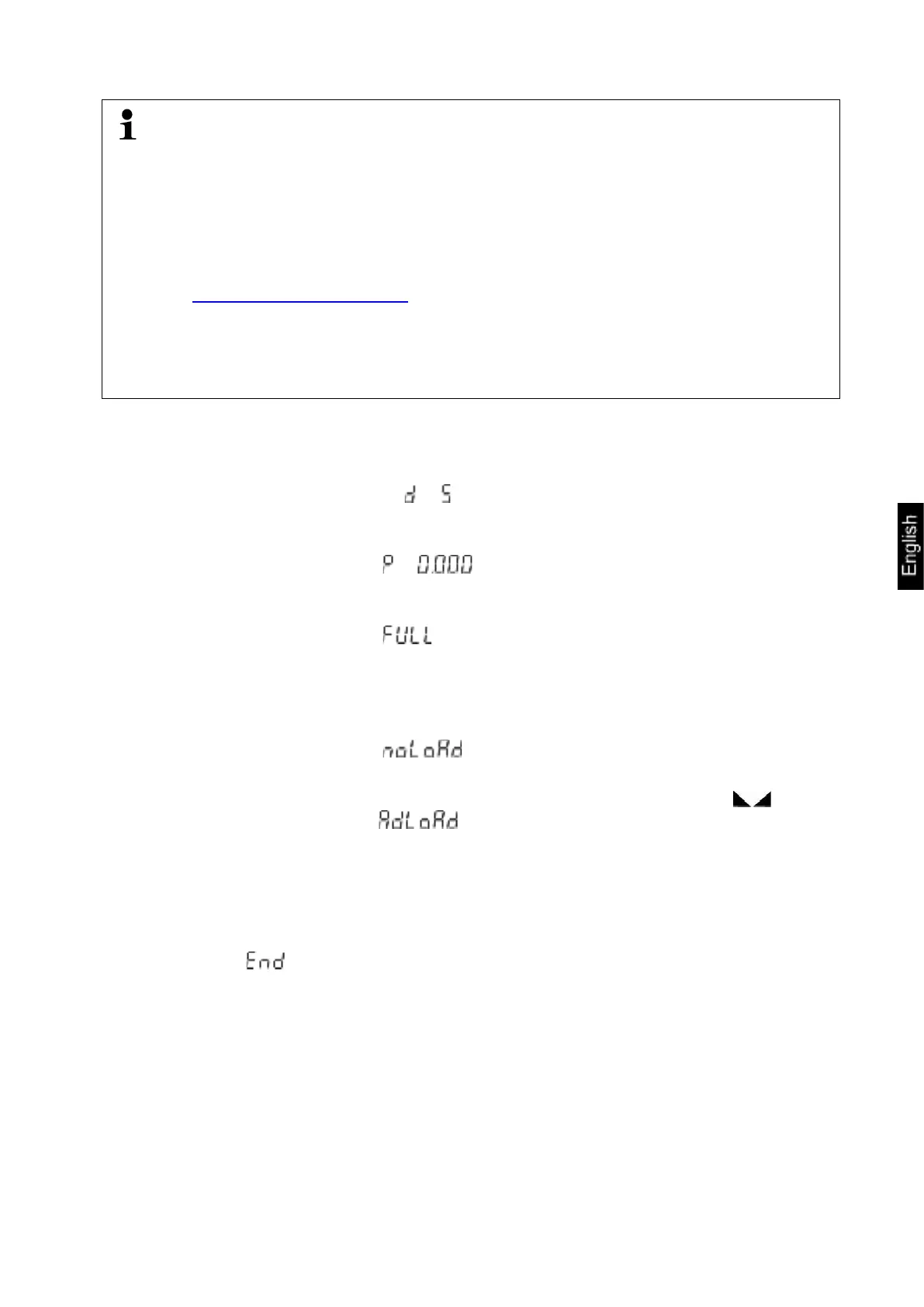

TOL and hold it for 10 s until < > is displayed.

If required, use TARE to change the interval (d),

you can choose from 1 d, 2 d, 5 d, 10 d, 20 d, 50 d.

Confirm by pressing TOL, < > will be displayed.

If required, use TARE to change the number of decimal places,

you can choose from 0, 0.0, 0.00, 0.000, 0.0000.

Confirm by pressing TOL, < > will be displayed.

Press TARE, the maximum load (Max) will be displayed. Red LED above PCS

will be lit.

If required, change the value using TARE and ZERO (Entering a value in the

numerical form, see chapter 3.2.1).

Confirm by pressing TOL, < > will be displayed.

Ensure there are no objects on the scale plate.

Once the stability check is completed successfully (red LED above is lit),

confirm by pressing TOL, < > is displayed.

Place the adjustment weight and confirm by pressing TARE.

The weight of the last used adjustment weight will be displayed. If required,

change the value using TARE and ZERO (Entering a value in the numerical form,

see chapter 3.2.1).

Confirm by pressing TOL.

Wait until < > is displayed.

After the successful adjustment, the scale will switch to the weighing mode again

automatically.

If there is any adjustment error or if an incorrect adjustment weight is used, the

error message is displayed. Repeat the adjustment process.

Remove the adjustment weight.

Loading...

Loading...