19

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

Seminar

TM

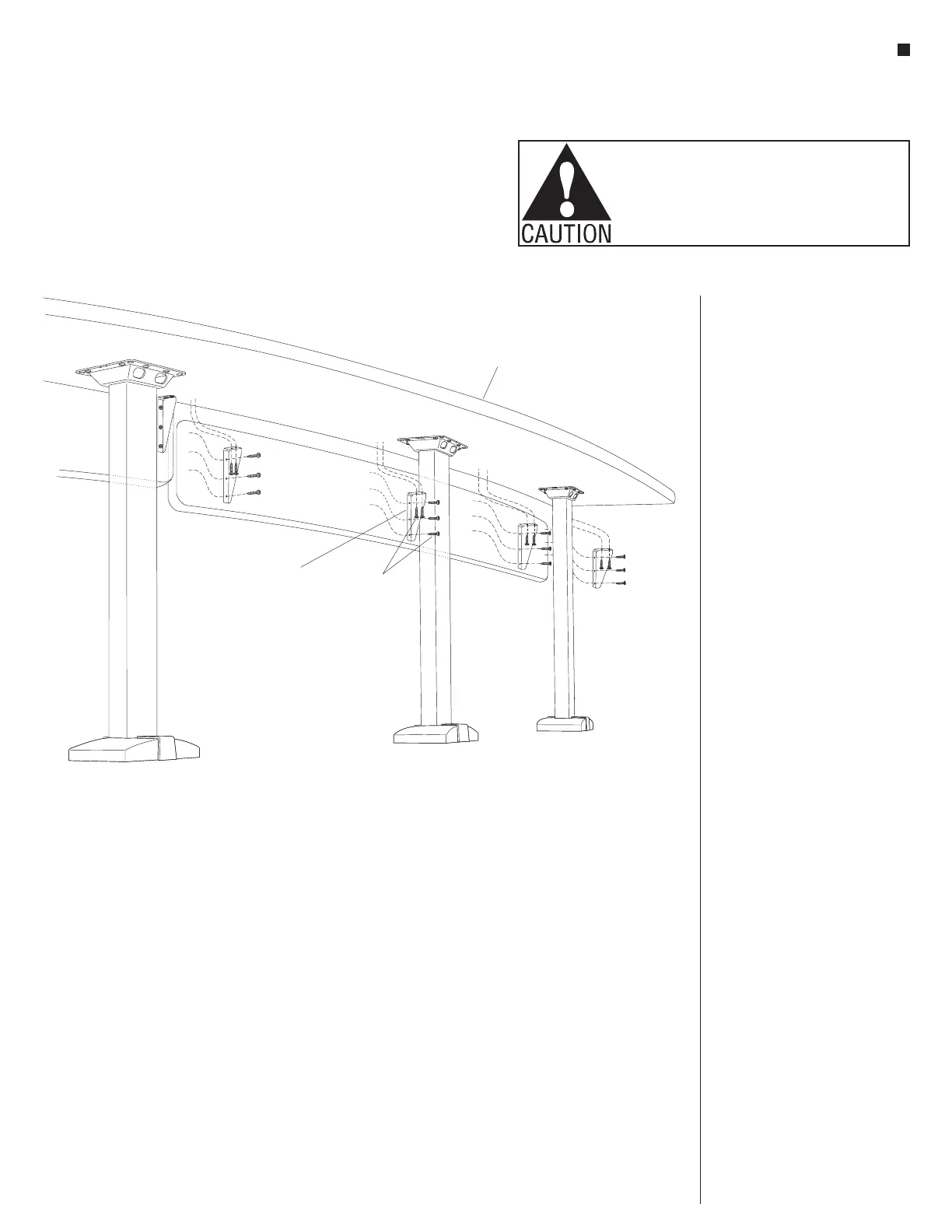

Tables with 4-Wire Power System - Modesty Panels

Assembly Instructions

tabletop

modesty panel

bracket

#10 x /”

3

4

screws

(12.0160)

Figure 19

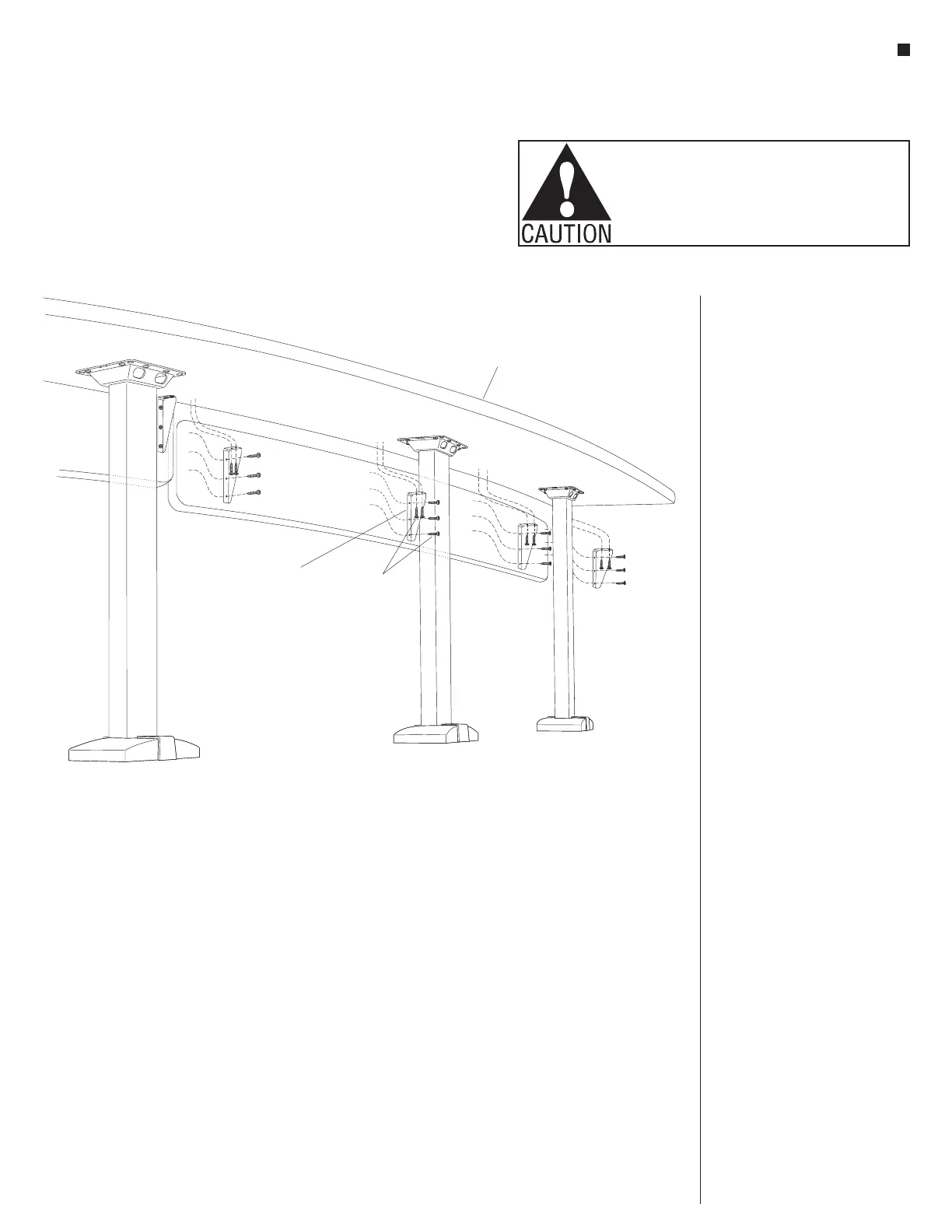

Figure 20

7

/”hole

8

tightening nut

draw bolt

locking sleeve

modesty panel

(back side)

7

/”hole

8

hardwood spline

KV joint fastener

Optional Laminate or Wood

Modesty Panel

38. Per the space-planning layout

and the identification numbers

on the back sides of the modesty

panels, lay the modesty panels out

where they will be installed to the

tabletops. Modesty panel lengths

are undersized on each end, thereby

creating a

1

/

2

” gap at the modesty

panel joints, and a

3

/

4

” to 2

1

/

2

”

space at the end-of-run. Refer to the

chart on the space-planning layout

for the number of brackets required

per modesty panel, and equally

space the brackets along the panel.

The two end brackets should be 2”

from the edge of the panel. Begin

assembly by installing the bracket

to the tabletop first (Figure 19).

Note: Care must be taken when

positioning the brackets to

ensure they do not interfere with

the tabletop mounting flanges.

When the bracket is installed to

the underside of the tabletop, the

shorter flange of the bracket must

be secured to the tabletop with two

#10 x

3

/

4

” screws torqued to

50 in/lb. Mounting holes under

tabletop must be pre-drilled with

an

1

/

8

” drill bit to maximum depth

of

1

/

2

”. Be sure that the longer

edge (which will be secured to

the modesty panel) is set back 1”

from the front edge of the tabletop.

After all brackets are secured to the

tabletop, carefully lift the modesty

panel into place and pre-drill holes

in modesty panel with an

1

/

8

” drill

bit to a maximum depth of

1

/

2

”.

Secure each installed modesty

panel bracket to the modesty panel

with three #10 x

3

/

4

” screws torqued

to 50 in/lb (Figure 19).

Note: To help support continuous

wood and segmented wood panels

during attachment, bar clamps may

be used.

Loading...

Loading...