20

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

Seminar

TM

Tables with 4-Wire Power System - Modesty Panels

Assembly Instructions

39. For Continuous Laminate or

Wood Modesty Panels, the

following steps must be completed

before mounting the panel to the

table, described in step 38.

Modesty panels are to be joined

together from behind with two KV

joint fasteners per pair of modesty

panels (Figure 20. First join both

modesty panels together, aligning

the hardwood spline (installed in

one modesty panel at the factory).

Check to make sure hardwood

spline fits snug in both modesty

panels. If it does not, lightly sand

down the spline so it does fit. If this

is not done, it may be difficult to

get a tight fit on the modesty panel

seam. The spline joint and modesty

panels seam are to be glued using

the adhesive supplied with the KV

fasteners. Do not use a wood glue

for seam gluing as the working

time for that adhesive is too short.

Then, thread each draw bolt a few

turns into each tightening nut and

press each pair up into a

7

/

8

” hole

and slot. The flat end of each draw

bolt will be visible in the

7

/

8

” holes

of the modesty panel being joined.

Insert locking sleeves into the

7

/

8

”

holes so that the slotted sleeve

engages the rounded collar on the

bolt (Figure 20). Tighten the nut

with a tightening tool or nail set.

Check the front side of the joint for

proper alignment. The joint should

be smooth and level with no gaps.

Adjust as necessary to achieve a

“seamless” look. Once the seam is

glued, use the C-clamps to clamp

either end of the seam. Allow one

hour for glue to set before attaching

panels to top.

Note: Each pound of pressure

on the tightening tool exerts 500

pounds of force on the joint.

Overtightening the KV fasteners will

cause the panels to delaminate.

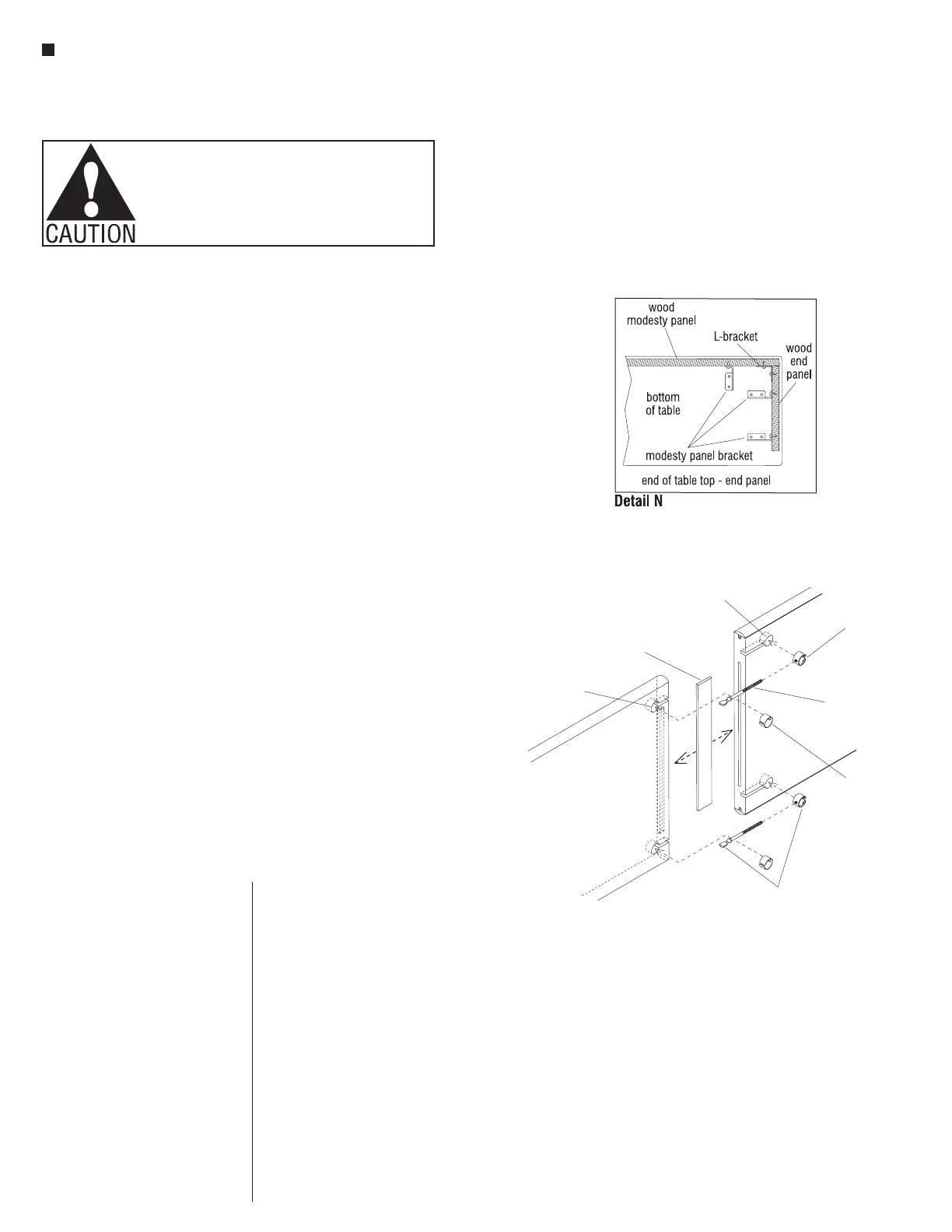

40. For Laminate or Wood

Modesty Panels with End

Panels, the end panels are to be

installed after modesty panels are in

place. End panels use two modesty

panel brackets and an L-bracket

in the corner where the two panels

meet (Detail N). Place the end

panel into position, then using

the L-bracket as a template, mark

the six mounting hole locations,

three to the modesty panel and

three to the end panel. Carefully

pre-drill mounting holes in each

panel to a depth of

1

/

2

” with an

1

/

8

”

drill bit, taking care to not pierce

through the end panel or modesty

panel. Use bar clamps to hold the

end panel in position and install

L-bracket with six #10 x

3

/

4

”

screws torqued to 50 in/lb

(Detail N). Adjust the clamped

end panel for desired reveal at

the end. Position the modesty

panel brackets at their installation

location and mark their mounting

hole locations. Using a

1

/

8

” drill bit,

pre-drill to a depth of

1

/

2

”, taking

care to not pierce through the end

panel. Mount two modesty panel

brackets to the end panel and

bottom of the tabletop using five

#10 x

3

/

4

” screws torqued to

50 in/lb at each bracket (Detail N).

Note: For full-height end panels

joining with full-height modesty

panels, two L-brackets are required.

tabletop

modesty panel

bracket

#10 x /”

3

4

screws

(12.0160)

Figure 19

Figure 20

7

/”hole

8

tightening nut

draw bolt

locking sleeve

modesty panel

(back side)

7

/”hole

8

hardwood spline

KV joint fastener

Loading...

Loading...