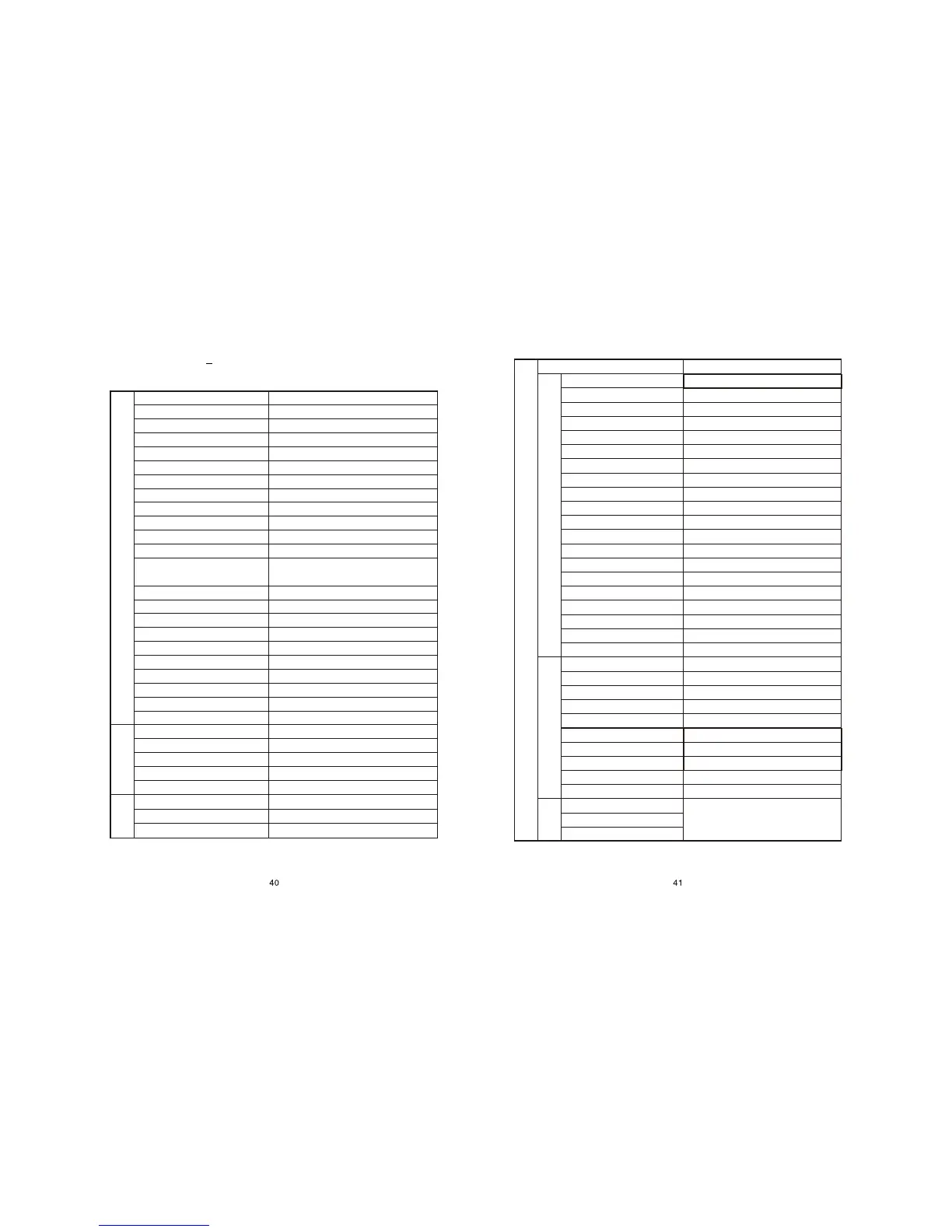

2.12 Troubleshooting Open-shelf diesel engine and quiet generating set

2.12.1General symptom and possible cause

The generator can not generate, generating set has no electricity or the

voltage is abnormal, the voltage is fluctuated when loaded.

Fault caused by electric machine.

1.

2.

3.

4.

5.

7.

8.

9.Open circuit of electric machine rotor winding coil.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.Insulation resistance of generator is decreased.

Check the wiring harness.

Check or replace terminal.

Remedy

Drain the fuel oil, check and clean.

Refill the fuel oil.

Turn it to START position.

Check.

Clean.

Switch on.

Clean.

Check, replace.

Check or replace.

Check, replace.

Check, replace.

Check, replace.

Check, replace battery or charge regulator.

Check or adjust lash.

Check or replace recoil part.

Check or replace starting motor.

Adjust or disassemble to clean

Check or replace.

Repair the fault.

Repair the fault

Adjust.

Fault

Deteriorated diesel oil in fuel oil.

Fuel oil is not sufficient

Fuel cock is not at START position

Diesel oil filter is clogged

The pump does not delivery oil

Oil nozzle is clogged

Engine cylinder has a seize fault.

Oil pump or nozzle is faulty.

Engine governor spring is faulty.

Valve lash is adjusted improperly.

Oil delivery pipe of oil tank is bent or oil pipe is clogged

Fuel injection pump and nozzle do not delivery oil

The governor lever of engine throttle is not at START position.

Engine oil filter is clogged causing low oil protection

Solenoid fuel valve is clogged or does not work because power off .

The governor lever of engine throttle is faulty

The contact of starting switch fails to function

Electromagnetic coil in starting motor is faulty

The starting motor has internal mechanical fault

Oil level switch (engine oil alerting apparatus) is faulty

The battery has no electricity, charge circuit is faulty

Valve lash is improperly adjusted or valve pad falls off

Driving gear for starting motor is abrasive or cracked

Generator has a overload or short circuit fault

Remove the high pressure oil pipe, check for delivery of oil, replace pump or clean.

Remove the high pressure oil pipe, check for delivery of oil, replace pump or clean.

Check the 12V power supply or replace solenoid valve.

Check and observe the engine rotation, disassemble the engine to replace faulted part.

Check the wiring harness of 12V battery with gauge panel.

Recoil part in recoil starting set is faulty

Power supply for starting circuit is faulty

The oil supply for oil-line is not sufficient.

The diesel engine can not start or difficult to start

Check exhaust-gas or observe engine rotation,

clean or replace oil nozzle.

Engine speed is unstable,

too high or too low.

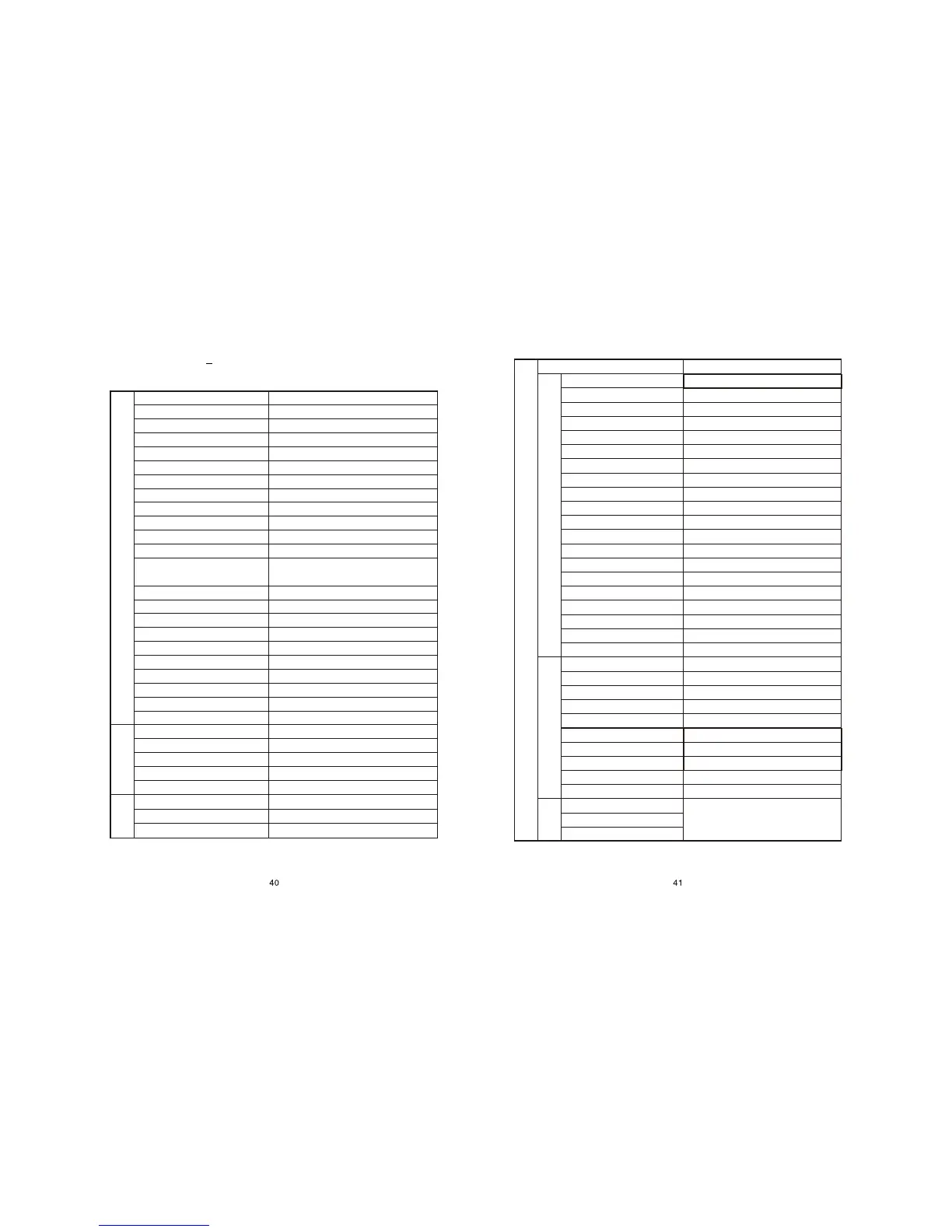

Gauge panel of

generating set

1. Air breaker fails to function

2.

3.

Check the wiring harness.

Check or replace receptacle.

The wiring of gauge panel is loosened.

The connection of receptacle is loosened or contact is melted.

Remove it and check for open circuit. The resistance reading in multimeter should be "0"

The lead-out of electric machine is loosened.

The four-port terminal of electric machine is cracked.

Open circuit of electric machine main winding coil

Short circuit of electric machine main winding coil.

Open circuit of electric machine secondary winding coil.

Open circuit of electric machine sampling winding coil.

Interturn short circuit of electric machine main winding coil.

Short circuit of electric machine rotor winding coil.

Loss of magnetism in electric machine rotor magnetic steel

Short circuit of electric machine rotor collector.

Fixed carbon-brush on electric machine stator is loosened or wear-out.

Rear end cover of electric machine stator is cracked.

Frictional short-circuit of electric machine stator and rotor.

Electric machine fault caused by wearing of engine output bearing.

Fan blade of electric machine is cracked.

High temperature overheating of electric machine stator or rotor.

Front end cover of electric machine is cracked.

Carbon-brush is sparking or wearing, or collector is darkening.

Check resistance value at terminal, reconnect or replace stator.

Check resistance value at terminal, reconnect or replace stator.

Check resistance value at secondary winding inserter, reconnect or replace stator.

Check resistance value at sampling winding inserter, reconnect or replace stator.

Check temperature of electric machine for overheating, check resistance value, or replace stator.

Check resistance value at collector, reconnect or replace rotor.

Check resistance value at collector, reconnect or replace rotor.

Check main winding for initial voltage when no AVR in electric machine.

Check resistance value at collector, reconnect or replace rotor.

Check resistance value at collector, reconnect or replace carbon-brush.

Check insulation resistance of stator and rotor by voltage withstanding gauge, or replace stator and rotor of electric machine.

Check resistance value at collector, reconnect or replace carbon-brush.

Check temperature of electric machine for overheating, check resistance value, or replace stator and rotor.

Check for abnormal sound or high temperature of electric machine, replace front end cover.

Check for abnormal sound or high temperature of electric machine, replace rotor.

Check for abnormal noise of engine or high temperature of electric machine at starting, replace engine.

Check temperature of electric machine for overheating, check resistance value, or replace stator and rotor.

Check for abnormal noise of electric machine at starting, check resistance value, replace front end cover.

Check output voltage or adjust AVR, check connecting harness

1.

2. Voltage excursion

3.

4. Electric component failed

5.

6.

7.

8.

9.

10. Incorrect wiring for exciting

Fault caused by automatic

voltage regulator AVR

Voltage can not be regulated, regulating potential meter is fault

Generator set automatically stopped after loading, current setting incorrect

After entering sampling signal no exciting output

The voltage can not be established because of insufficient residual voltage of electric machine

Power loss is increased because of higher voltage output of secondary winding

The voltage deviation of zero load and full load is too large , voltage regulating rate is low

The rising of voltage of generating set is high after capacitive load

Check output voltage or adjust AVR, or replace AVR

Correct wiring

Check loading, decrease load; check the voltage of AVR secondary winding, or replace AVR

Check AVR and the temperature of electric machine for high temperature, or replace electric machine or AVR

Check that the voltage of secondary winding should not above 140 V

Check that the voltage of main winding should be above 6 V without AVR in electric machine

Check exciting output voltage of AVR or adjust AVR, or replace AVR

Replace AVR

Check output voltage or adjust AVR, or replace AVR

Fault

Remedy:

Fault of intelligent

control panel

1. No display on screen.

2. Display wrong code.

3. Can not start.

Check 12V power supply of generating set

and check wiring for loosening or replace

display screen.

Loading...

Loading...