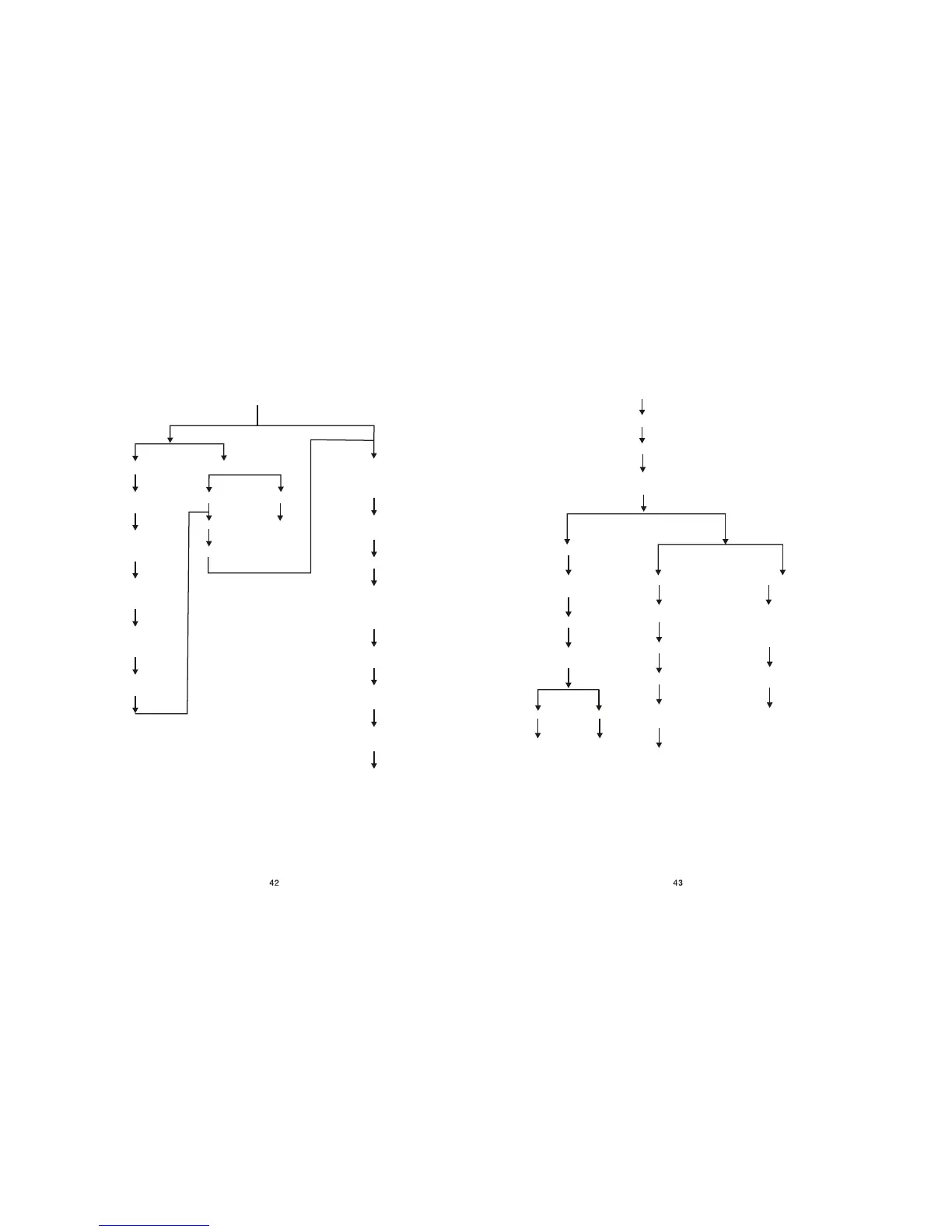

Check gauging system in panel

Check the connecting plug for loosening

Check the air switch for damage

Check the harness of air switch for dropout

No voltage (No electricity generated)

Have voltage

Check AVR secondary winding

for 3-4V voltage at swtiching on

Check AVR

Check connector of AVR sec-

ondary winding for loosening

Check AVR for output

Check AVR for

damage

Have no voltage

Check electric

machine

Check magnetic steel of rotor

for loss of magnetism, check

that the polarity of magnetic

steel is not reversed

Check rotor section

Check carbon brush of rotor

and collector for contact

Check rotor for open circuit

Check collector for short circuit

Check secondary winding

connector for loosening

Check stator section

Check that the connection of

quadbit line bank and gauging

panel is correct and is not lo-

osened

Check stator winding for open

circuit

Check stator winding for inte-

rturns short circuit

(2)Troubleshooting steps for no voltage

(Fig. Flow chart for diesel 2)

2.12.2 Flow Chart of Troubleshooting

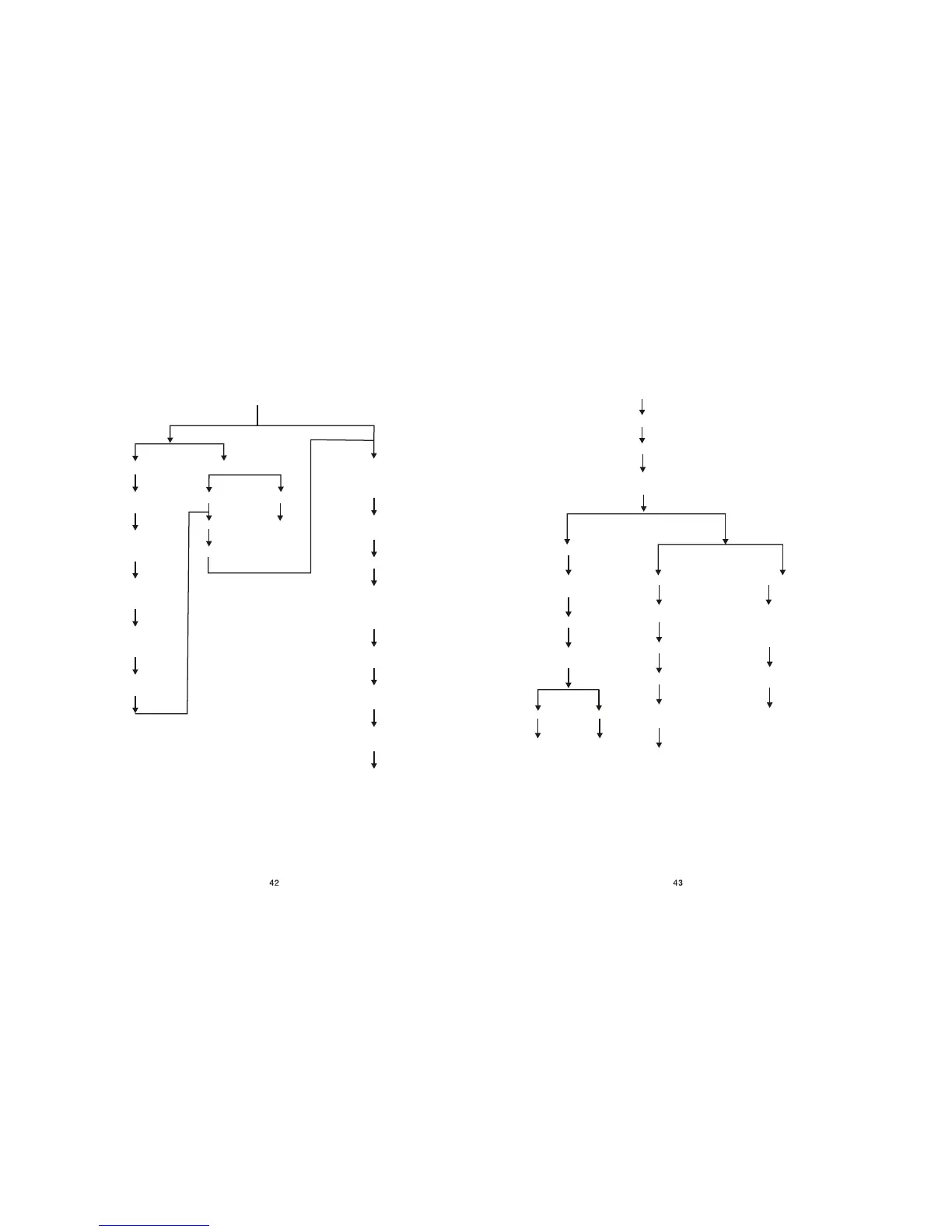

(1)Troubleshooting steps for difficult starting of diesel engine set

(Fig. Flow chart for Diesel 1)

(

Circuit and battery section

Difficult starting of failure to start

Electric starting Recoil starting

Check the relay

of electric starter

for acting

Check the battery

for sufficient voltage

Check for 12V

when starting

switch at START

Check electric starter

spark plug test

Check the harness of

12V battery of electric

starter for 12V

Can recoil Can not recoil

Check flywheel

or hand disk

Check oil system

Oilway and fuel section

Check that there is oil in tank,

Check that the oil switch is on,

Check oil tank for clogging and

leakage

Check the inlet valve and outlet valve

in cylinder head cover for damage

Check the gasket of cylinder head

cover for damage and leakage

Check the oil piping for clogging,

bending, seizing, and air presence

Check carburetor solenoid valve in

carburetor system for intactness and

seizing, check oil and air piping for

clogging.

Check the fuel filter for clogging

Check the location and function of

main damper and throttle of carburctor

Check that the clearances between

piston, piston ring and cylinder sleeve

are not excessive, the liner is not seized

Loading...

Loading...