4.1.5 Air cleaner

A dirty air cleaner will obstruct air from entering carburetor, thus reduces the

engine working efficiency. If the engine is running in dusty area, clean the air

cleaner more frequently.

Caution: Never run the engine without the element or with a defective element,

the dirt may enter into engine to accelerate the engine damage.

Checking/cleaning:

(1) Loosen screws on service cap, remove the service cap.

(2) Push off the locking plate on the top of air cleaner, remove the air cleaner.

(3) Take out the filter element.

(4) Wash the element in warm soap water, rinse it and air dry completely. Or

clean with high fire point solution and air dry.

Soak the element in clean engine oil, squeeze out redundant engine oil. The

redundant engine oil may prevent air to enter into foam element and would smok

at engine starting.

(5) Reinstall the element in air cleaner. If necessary, clean the air cleaner rubber

and housing. Make sure that the seal ring of air cleaner cover is secured.

(6) Reinstall the air cleaner cover. Reinstall parts in order. Lock the locking plate

on the top of air cleaner. Make sure that the seal ring of air cleaner cover is

secured. If the seal ring of air cleaner cover is damaged, replace it.

(7) Reinstall the service cap.

Caution: If the cover of air cleaner installed not tightly, it would fall during engine

running due to vibration. Never run the engine without air cleaner or with a

defective air cleaner to prevent accelerated wear of engine.

Service: The fault phenomena is fluctuation of engine running and incapable of

power raising-------insufficient air intake.

Cause: (1) Dirty air enters; (2) Exhaust gas feedbacks during engine running,

which causes incomplete combustion in engine and carbon deposition on oil

nozzles.

Remedy: Repeat the above-mentioned steps for cleaning. Refer to engine service

for oil nozzle faults.

4.1.6 Muffler

a. Removing and reinstalling

Caution: Remove and reinstall the muffler after the engine is cooled down.

(1)Protective hood of muffler

In quiet generating set the cooling plate must be removed, then remove the

muffler.

(2)Muffler (Installation: Before installing, tap muffler with a plastic hammer to

remove internal carbon deposition.)

(3)Gasket of muffler (Can not be reused)

Service 1: The fault phenomena is black smoke emitted from exhaust port during

engine running -------insufficient air intake.

Cause: (1) Dirty air enters; (2) Exhaust gas feedbacks into air cleaner during

engine running, which causes incomplete combustion in engine and carbon

deposition on oil nozzles.

Remedy:Repeat the above-mentioned steps for cleaning. Refer to engine service

for oil nozzle faults.

Service 2: The fault phenomena is black smoke emitted from exhaust port during

engine running ------generating set is overloaded

Cause:1.Generating set is overloaded. 2.Engine oil nozzle and oil pump have

faults causing incomplete combustion in engine and carbon deposition on oil

nozzles.

Remedy: 1.Repeat the above-mentioned steps for cleaning. 2.Reduce the loading

power of generating set. 3. Refer to engine service for oil nozzle faults.

4.2 Control panel

This section mainly deal with the remedy for faults caused by air switch, voltmeter,

electric switch lock, receptacle or PCB in control panel, and actions which should

be taken while the generating set faults such as no voltage output, no voltage

indication, not starting, automatic stopping, etc. present.

4.2.1 A.C. receptacle

Check: Connect two poles of receptacle with a jumper. The current should flow

normally between conductor terminals. There is current passed between

receptacle ground terminal and receptacle installing set.

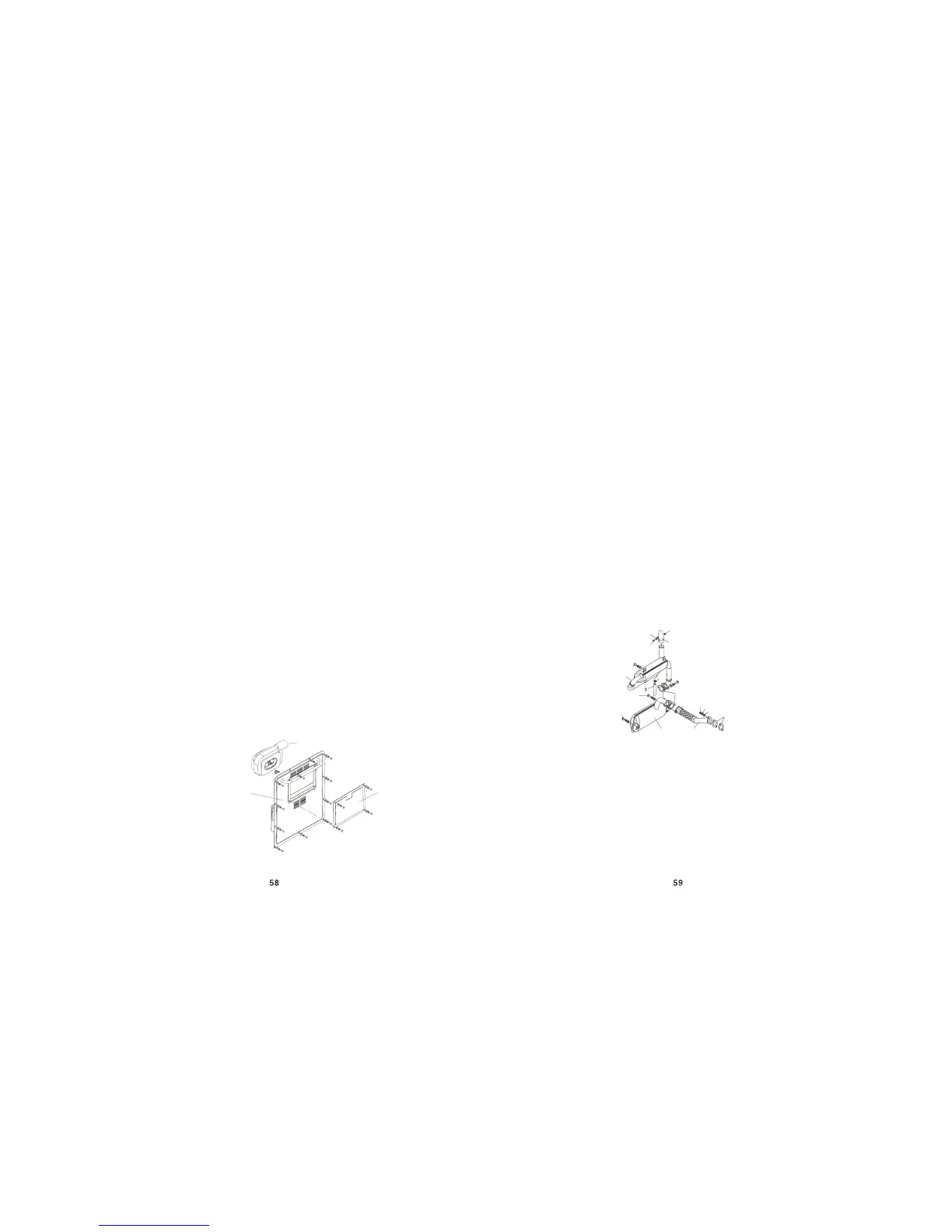

Air cleaner

Right side plate

Cover plate of

cleaner

(Fig.) Cleaning of air cleaner

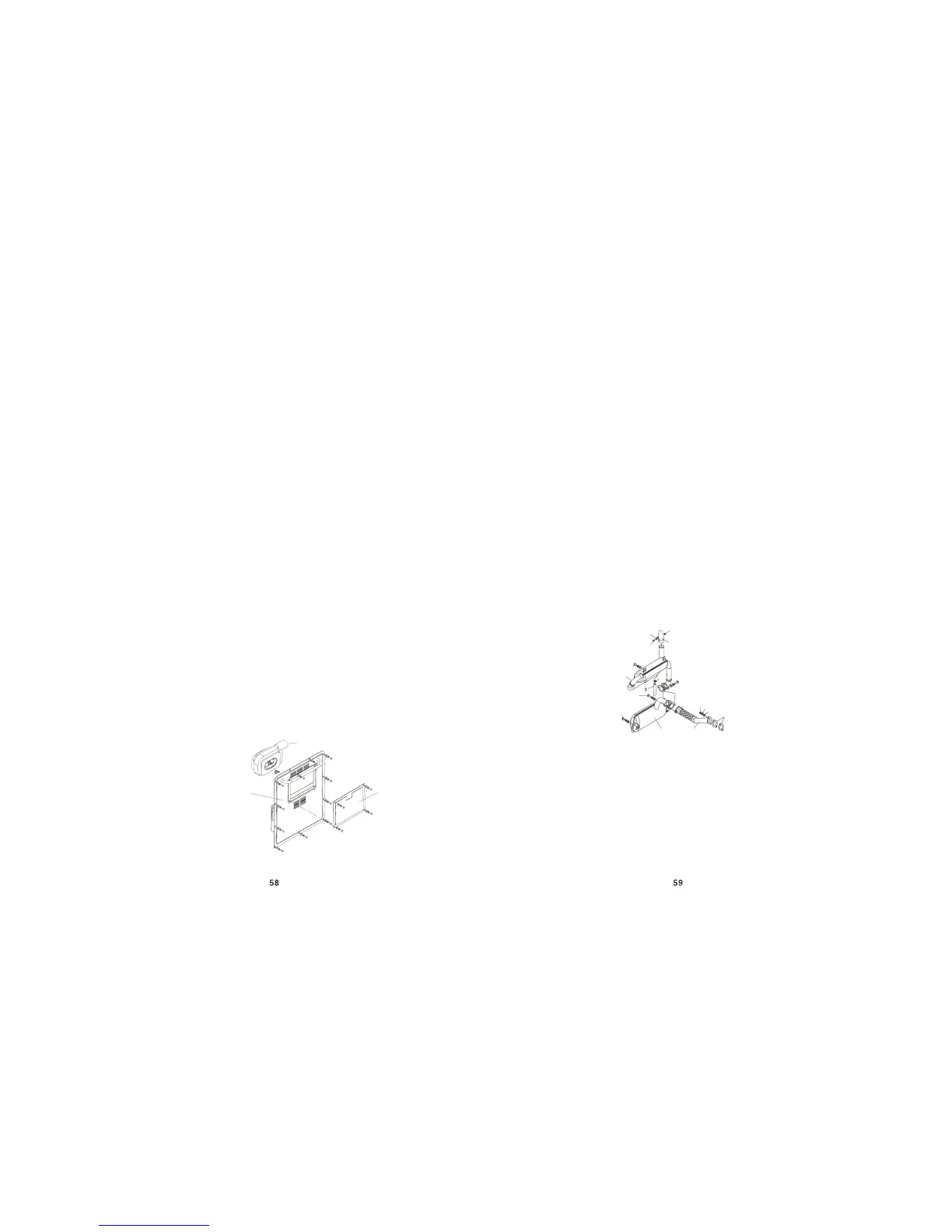

Nut

Tail-gas turning weldment

Plain washer

BoltM6x30

Second stage muffler assembly

Bolt M8x30

Bolt M8x16

First stage muffler

assembly

Exhaust pipe assembly

Nut M8

Buckle I

Spring washer

Plain washer

Gasket for exhaust pipe

(Fig.) Muffler

Loading...

Loading...