— 14 —

(Reference)

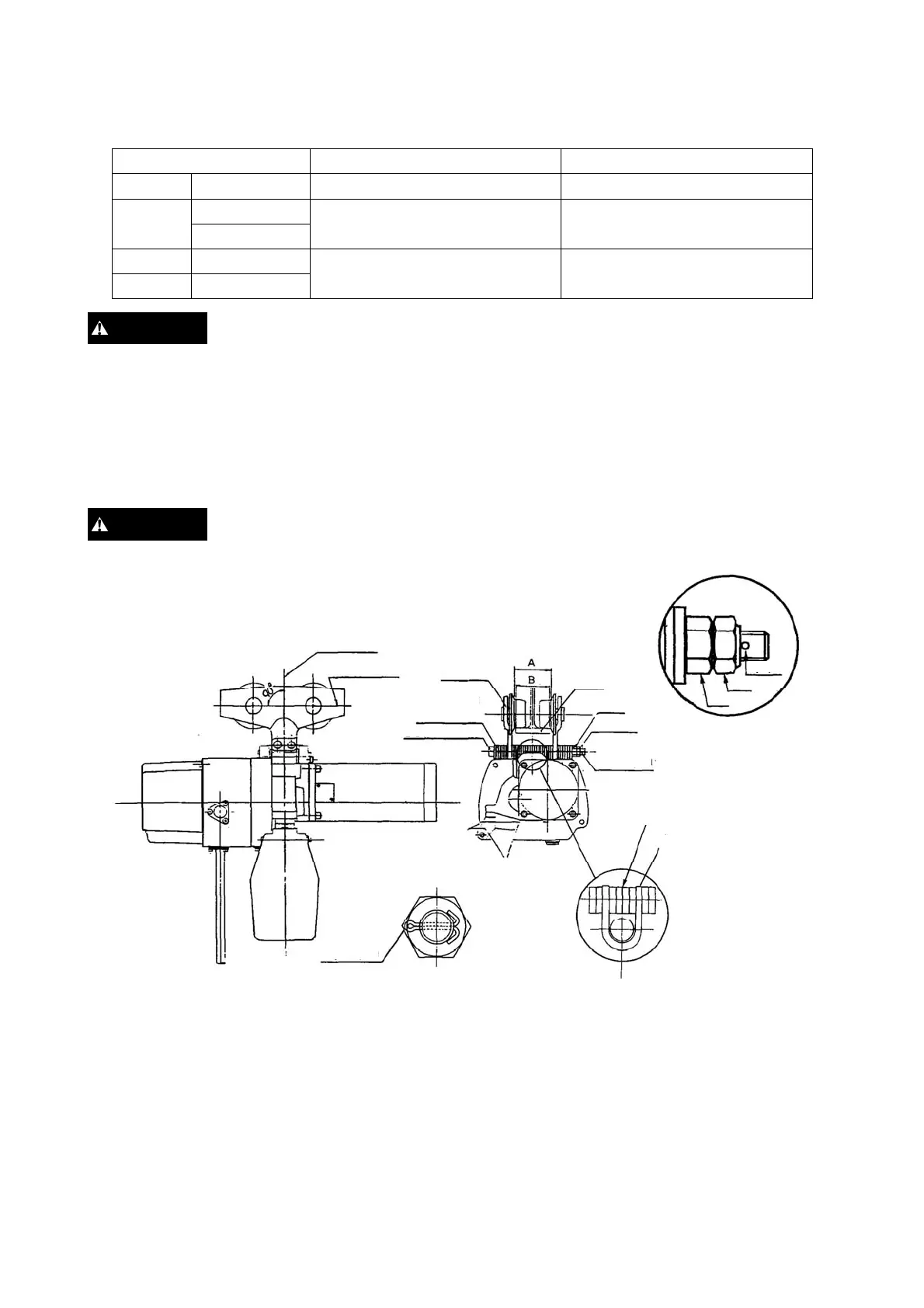

Rail width Inside trolley frame Outside trolley frame

50 H-steel Right/left, 8 pcs. each Right/left, 8 pcs. each

68

H-steel

Right/left, 11 pcs. each Right/left, 5 pcs. each

I-steel

98 H-steel

Right/left, 16 pcs. each Right/left, 0 pcs. each

100 I-steel

: Incorrect number of adjusting spacers may cause the trolley not to move or to

drop. To avoid these hazards:

ALWAYS make sure to use all 32 pieces and confirm that A-B ≒ 3 mm.

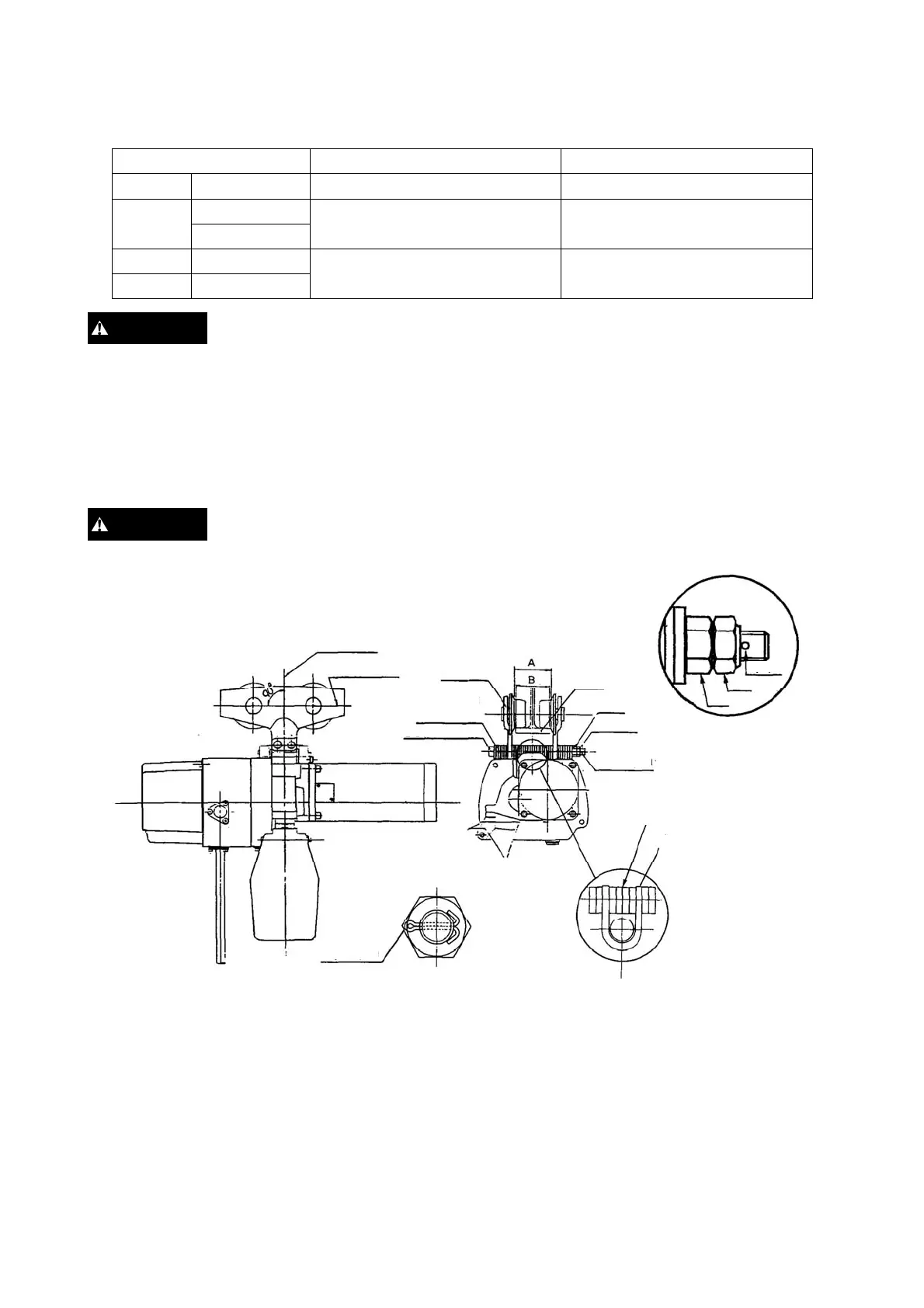

* Fitting of socket bolt

Set the trolley so that the wheel axis is right angle to the load line. Attach the socket bolt, nut and U nut

(double nut system), adjusting the clearance of 2mm or less between the split pin hole and U nut with 2

Adjusting Spacers and 2 Adjusting Spacer-Bs, and then tighten them and secure the split pin to the bolt.

: To avoid the trolley from dropping, firmly fasten the socket bolt, nut and U

nut. Insert split pin and bend its ends 90° or more.

WARNING

WARNING

Load line

Split pin

U nu

Nut

Wheel axis

Trolley

frame

Rail

djusting

spacers

Socket bolt

Nut

U-nut

Split pin

Insert 4 adjusting spacers inside

the top yoke.

Top yoke

(of electric chain hoist)

Split pin

Loading...

Loading...