— 22 —

5-6. Inspection Methods and Judgment Criteria

Item Inspection Methods Discard limit/criteria Measures

1. HOIST BODY

(1) Casting damage

Check visually.

・ No cracks on hoist body.

Replace.

(2) Abnormal sounds

during operation

Lift and lower a light

load.

・ No vibration or irregular noise

from the motor or from inside the

hoist body.

Overhaul.

(3) Gear oil quantity;

contamination

Check visually.

・ Change gear oil regularly,

matching usage frequency.

Replace.

(4) Controller cover

damage

Check visually.

・ No deformation or cracks.

Replace.

(5) Name plate damage Check visually.

・ Capacity should be legible.

Replace.

(6) Cable and cord joint

damage

Check visually.

・ No damage or loose screws.

Replace/repair.

(7) Brake function Check brake slipping

on lifting or lowering

with no load.

・ Braking distance: approx. 5 chain

links.

Ask service shop to

inspect and repair.

Check brake slipping

on lifting or lowering

with rated load at

high speed.

・ Braking distance: approx. 5 chain

links.

Ask service shop to

inspect and repair.

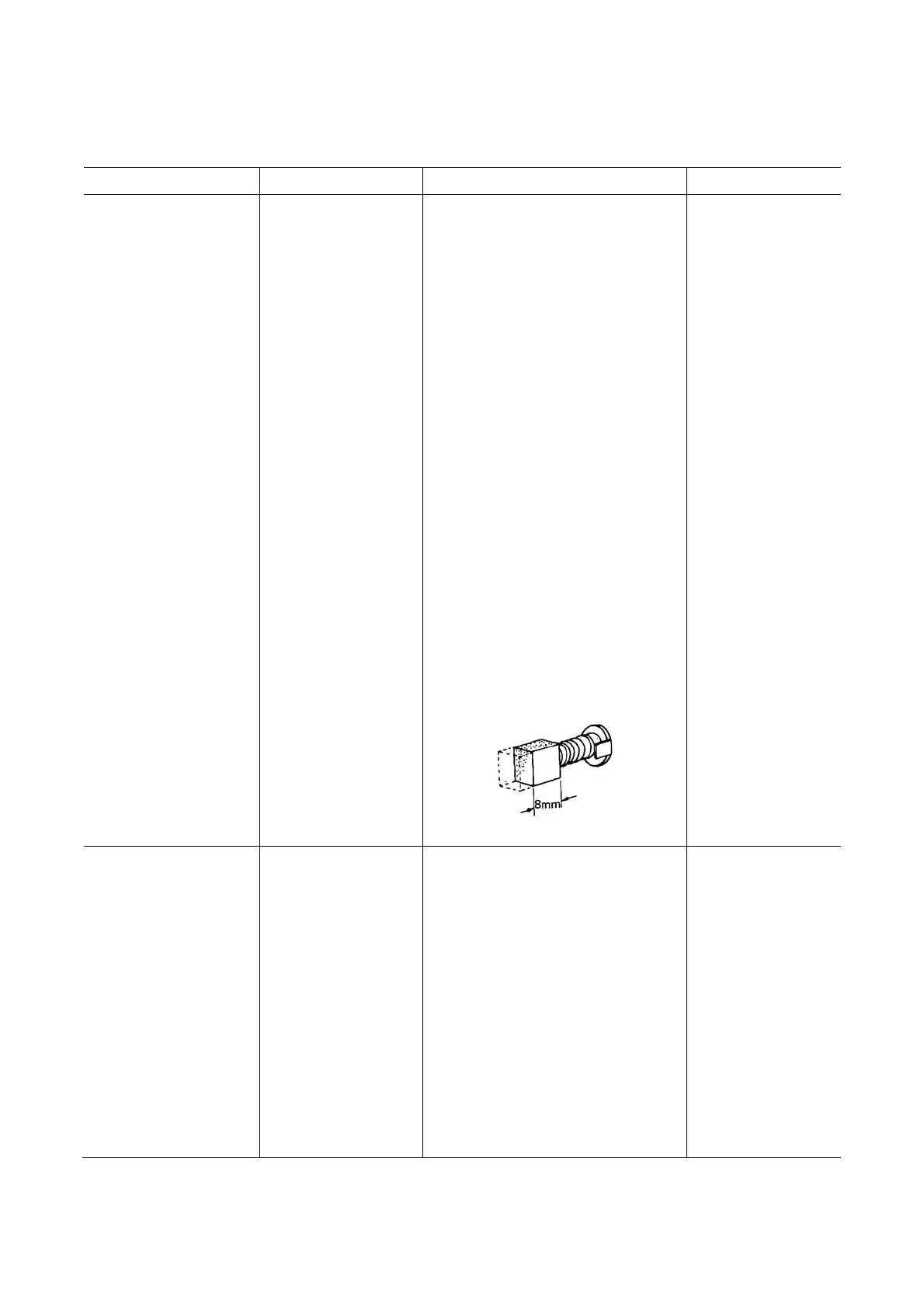

(8) Brush Check visually.

・ The discard limit of this brush is 8

mm (brush should not be worn past

this limit).

Replace.

2. OPERATION SWITCH

(1) Function

Operate switch with

no load.

・ The bottom hook shall lift and

lower.

Check power source

and make sure cord

is connected.

Replace if defective

(electrical

equipment

included).

・ To change from low to high speed.

(Dual-speed and dual-speed

cylinder types)

Replace.

(2) Case cracking Check visually.

・ No cracks.

Replace.

(3) Loose wiring joints Check visually.

・ No loosening or dropping of

screws.

Repair.

Loading...

Loading...