KMS MD35 manual

Version 4.16 15

Important is that the cam reference point is not set on the edge of the (missing) tooth, but as far as

possible in the centre of the (missing) tooth. With the pattern on the right in the figure above, it‟s

impossible to set the cam reference point in the middle of the tooth. When the sensor is positioned

in the middle, 360 crank degrees later, the signal will be the same. The top tooth is wider than the

bottom tooth. The cam reference should be set in the middle of this extra width.

3.2.4.1.1.3 Coil on time

A coil should be charged before every discharge (plug spark). The coil charging time is indicated in

ms. It should normally be 1.4 to 3.5 ms depending on the type of coil. Longer coil charging leads to

unnecessarily high power consumption and heat development, shortening the service life of the coil.

Warning:

The coils can only be operated via a driver circuit. If the computer is

connected to the coil directly, the ECU can get damaged beyond repair.

Many modern coils feature a built-in driver stage. However, if a coil without

an integrated driver stage is used, the separate KMS ignition driver module

with partnumber 01-01-04-0001 will be needed.

Dis-coil:

The choice is between dis-coil (wasted spark) and single coil control (rotor and distributor cap). If

you have a dis-coil (and also when using coil per plug wasted spark) the box has to be ticked.

Direct-firing:

This option detects the compression stroke which enables you to ignite directly on one cylinder at a

time (you have to connect the cam sensor to make this work). With dis-coil it is a wasted spark.

Separate coils per cylinder is requiered for this sequential ignition. Make sure that the connections

of the KMS ECU to the single coils are in the right igniting order. For example a 4 cylinder inline

engine with firing order 1-3-4-2. The coil outputs get activated in the order 1-2-3-4. For direct-firing

coil output 1 fires cylinder 1, coil output 2 fires cylinder 3, coil output 3 fires cylinder 4 and coil

output 4 cylinder 2.

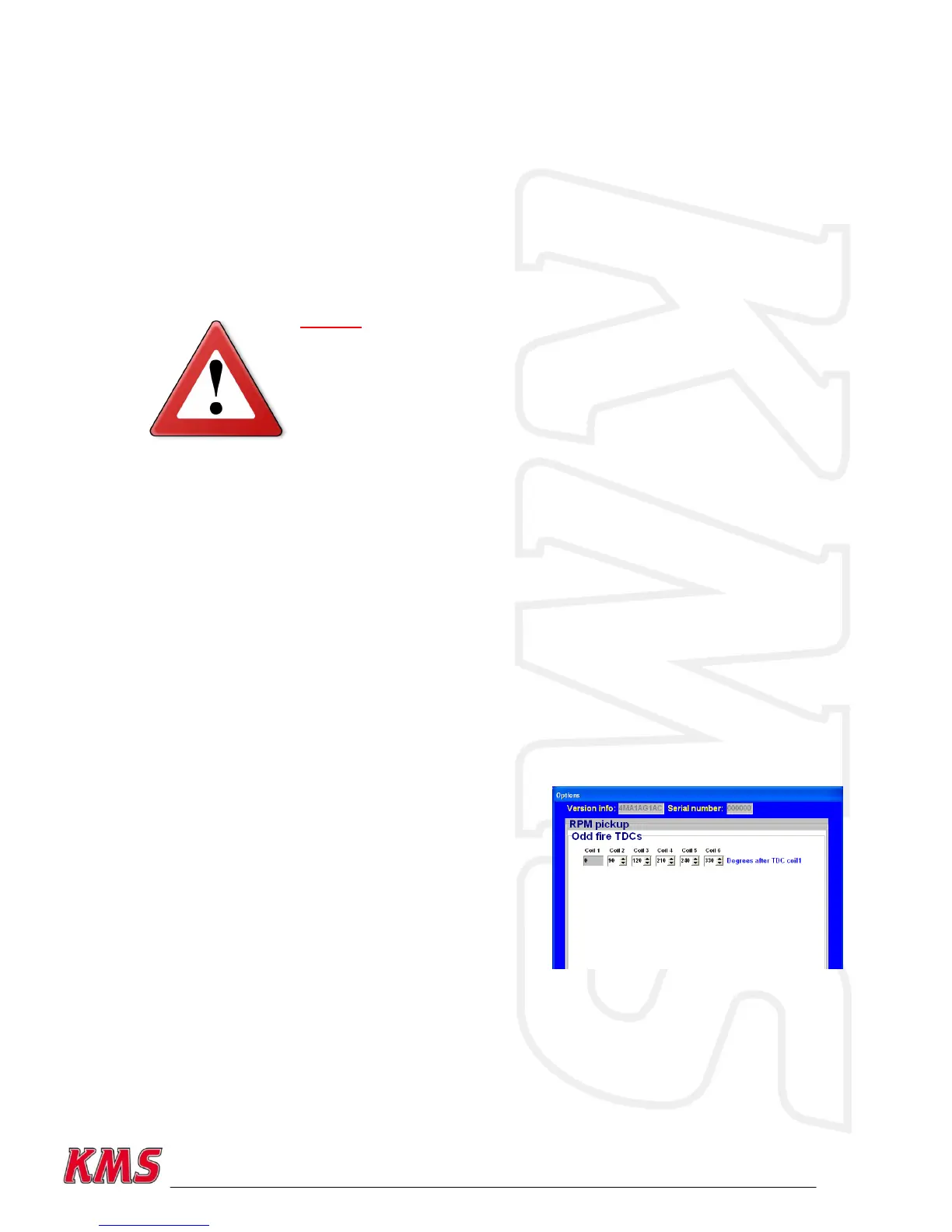

Odd fire TDCs:

You can advance/retard the ignition time for every

cylinder. This can be useful at assymetrical engines.

You have to fill in the angles of different cyliders. The

degrees must be ascending with a maximum of 360

degrees. How to determine the odd fire TDC‟s for a V6:

First check what the engine firing order is. The cylinder

that is in TDC and where the reference point is set to is 0

degrees. Devide the number of cylinders in the right firing

order evenly over 720 degrees (= 2 rotations for 4 stroke).

The cylinders on the same crankpin but later in the firing

order and different bank have to be corrected for the angle

of the block. So the degree for these cylinders isn‟t on the degree calculated before when deviding

720 dregrees through all cylinders but the angle of the block. The degree for the second cylinder on

the same crankpin is the sum of the degrees from the first cylinder on the same crankpin and the

angle of the block.

In the software you can fill in a maximum of 360 degrees after TDC so you have to subtract 360

degrees from the cylinders which have higher degrees than 360 (this is needed in case of a

camsensor failure to keep the engine running on all cylinders but as a wasted spark).

Loading...

Loading...