KMS MD35 manual

Version 4.16 14

TIP: set for the complete rpm-range the ignition advance map to 10 degrees. The ignition advance

read out on the software screen will be stable and doesn‟t change when your engine speed varies a

bit.

For example your reference point set in the software is 90 degrees. The ignition advance 10 degrees

at 1000 rpm. Checking with the timing light on cylinder 1 gives you 5 degrees ignition advance.

That‟s a deviation of 5 degrees which must be corrected on the reference point. The correct

reference point is 90 – 5 = 85 degrees.

Warning:

When using wasted spark, the read out on the timing light must be divided

by 2. A timing light displaying 20 degrees advance with wasted spark is in

reality 10 degrees ignition advance.

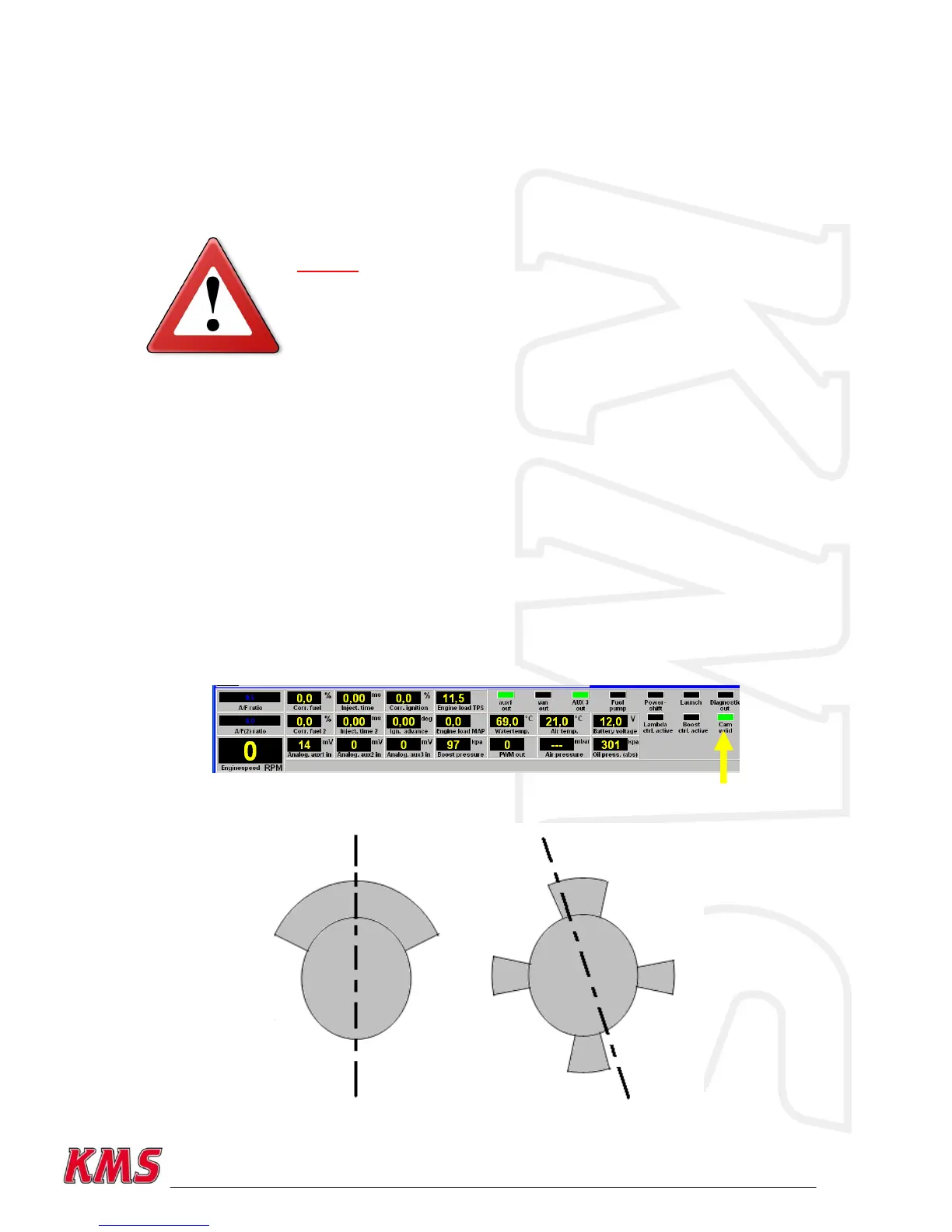

3.2.4.1.1.2 Cam pickup

You can enable cam pickup for recognizing the compression stroke for direct fire.

Active:

The cam reference can be set between -180 and +180 degrees TDC of the compression stroke.

Select the kind of pickup signal, high or low. There is a easy way to find out whether the signal is

high or low. Just apply power to the KMS system (engine not running) with the cam sensor

connected. Right below in the main screen in the communication bar of the KMS software you can

find „Cam valid‟. When the cam sensor signal is „high‟ at the degrees after TDC (set at the cam

reference point) of the compression stroke the cam valid control light in the communication bar

lights (see figure below). 360 crank degrees later the signal must be low. If the sensor signal is „low‟

in TDC of the compression stroke the cam valid control light doesn‟t light up. 360 crank degrees

later the signal must be high.

The cam reference must be set in a way that the cam signal in the compression stroke is always the

opposite signal of the exhaust stroke. In the figure below an example of 2 cam patterns is shown.

Loading...

Loading...