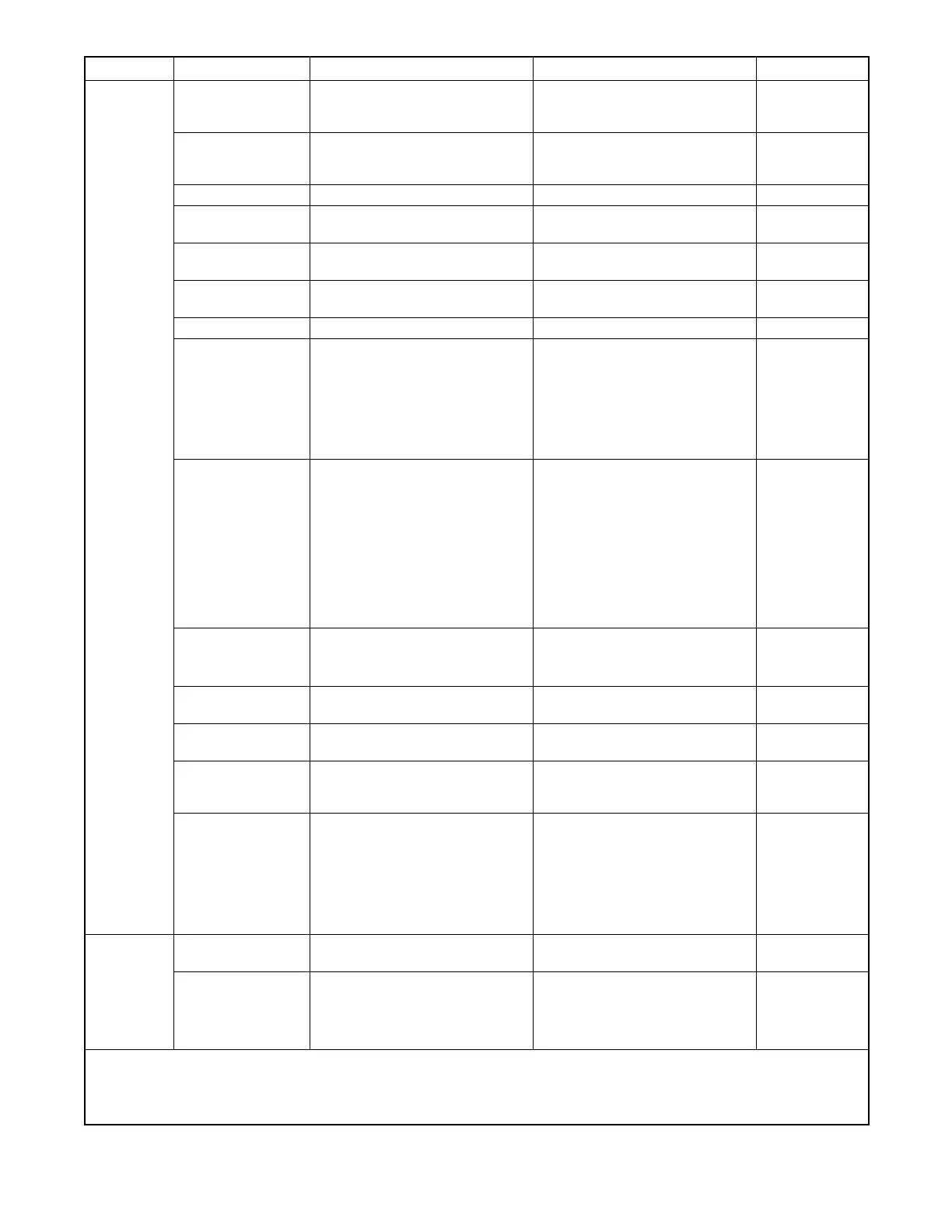

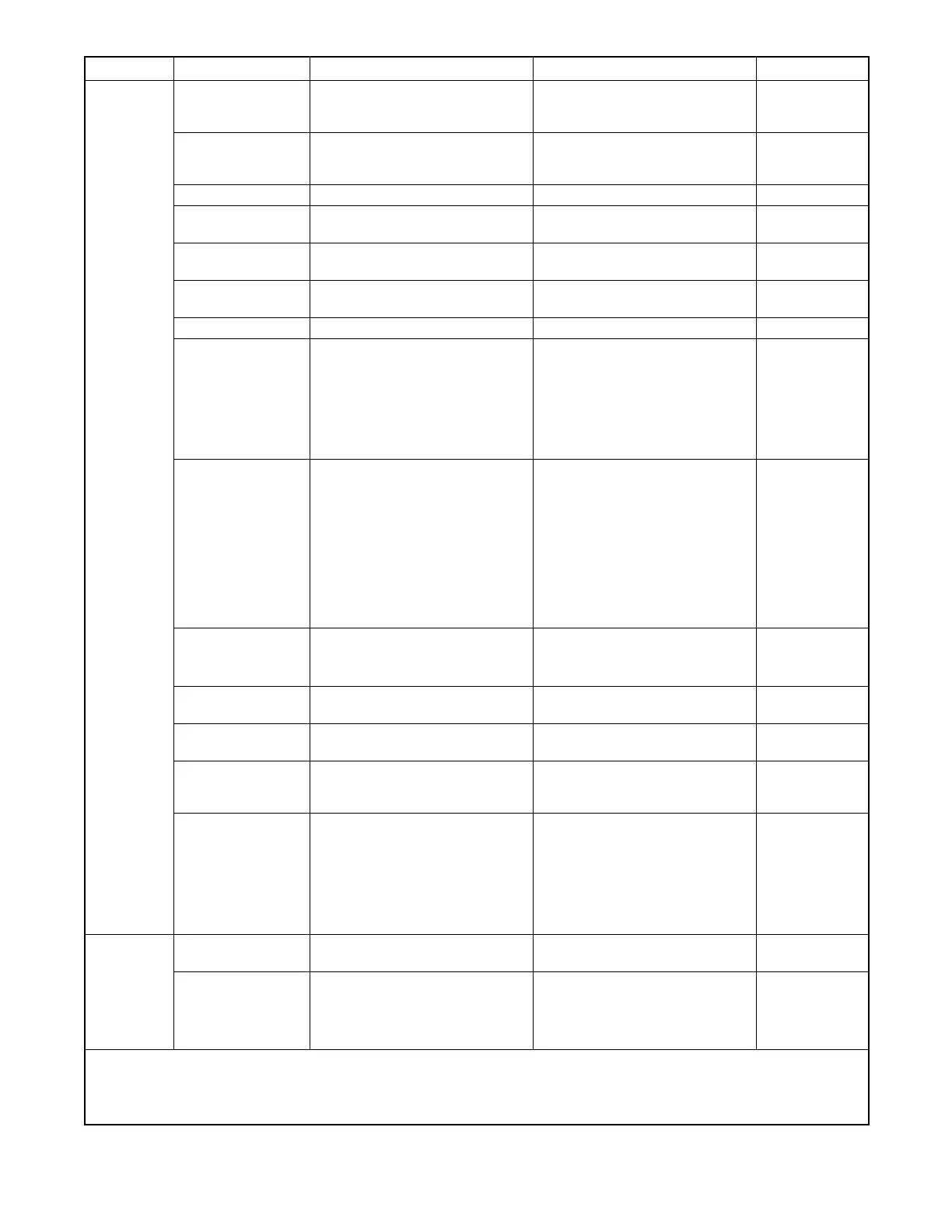

TP-6735 7/17 31Section 3 Troubleshooting

Problem ReferenceCorrective ActionTestPossible Cause

Stops

suddenly

Fault shutdown Check for a fault shutdown code

on the controller display. Identify

the cause of the fault.

Correct the fault and then press

the controller’s OFF button to

reset the controller.

Section 4.8

Section 5.10

No fuel Check fuel valves and fuel supply. Open manual fuel valve. Contact

fuel supplier to replenish fuel

supply.

—

Fuel line restriction Inspect fuel lines. Clear restriction. —

Fuel lines too long Check fuel line length and pipe

size.

Contact fuel supplier to replace

fuel lines with larger pipe.

Generator set

S/S, I/M

Air cleaner clogged Check for a dirty air cleaner

element.

Replace air cleaner element. O/M

Blown fuse Check fuses F2 and F3 on the

controller.

Replace fuse. If fuse blows again,

test generator components.

Section 5.14.2

Spark plug(s) Check spark plug(s). Replace or regap plug(s). O/M

Engine overheated

(hot engine only)

Check air intake and generator

set enclosure air inlets and outlet.

Use oxygen sensor to check fuel

mixture.

Check oil level.

Clear air intake and enclosure air

inlets and outlets.

Adjust fuel mixture.

Add oil. Check and replace oil at

the intervals shown in the Service

Schedule.

O/M

Section 5.11

O/M

Low oil pressure

(LOP) switch

Check oil pressure.

Attempt startup. If unit shuts

down, remove lead from LOP

switch and reset controller. A

successful restart attempt

indicates a faulty LOP shutdown

switch.

Note: Check engine oil pressure

before performing test and/or

replacing LOP shutdown switch.

See engine S/M.

Replace faulty LOP shutdown

switch.

Note: Check engine oil pressure

before performing test and/or

replacing LOP shutdown switch.

Engine S/M

Section 5.10.2

Fuel valve/fuel

regulator

Check fuel valve connections.

Check regulator/valve operation.

Check fuel pressure.

Tighten fuel valve connections.

Replace damaged wires.

Replace regulator or valve .

Section 5.11

Engine overloaded Reduce electrical load and check

operation.

Unplug some lights or appliances

connected to the generator set.

—

Magnetic pickup

connections

Check for loose connections to

the mag pickup.

Tighten connections to the mag

pickup. Replace damaged wiring.

Section 5.9

Ignition module Test the ignition system according

to the instructions in the engine

service manual.

Service the ignition system

according to the instructions in the

engine service manual.

Engine S/M

Loss of generator

output voltage to

controller

Check connections at P2 plug.

Check continuity of AC sensing

leads 11 and 44 (1 ph) or V7, V8,

and V9 (3 ph).

See Section 5 for alternator test

procedures.

Tighten connections at P2 plug.

Replace wiring if damaged.

Repair or replace components if

necessary, as indicated by tests in

Section 5.

Section 7

Section 5.3

Section 5

Overheats

Inadequate cooling Inspect engine and enclosure for

air intake obstructions.

Clear any air intake obstructions. O/M

Fuel mixture

adjustment

incorrect

Use an oxygen sensor to check

the fuel mixture.

Readjust fuel mixture.

Note: Adjusting the fuel mixture

may void the emission

certification.

Section 5.11

W/D = Wiring Diagram(s) (Section 7) S/S = Generator Set Specification Sheet O/M = Generator Set Operation Manual

I/M = Generator Set Installation Manual Engine S/M = Engine Service Manual

* RDC controller settings can be checked and adjusted using the controller user interface or using a personal computer running SiteTech

software. DC controller settings can only be changed using SiteTech.

Loading...

Loading...