STEP

6

-

Piston, Connecting Rod Assemblies:

-

A.

Place flywheel loosely on crankshaft and tip engine using flywheel as supporting base.

B.

Separate rod caps from assemblies but be careful not to mix caps.

C.

Lightly oil bearings, crank pins, piston rings, then rotate rings so that gaps are not in line.

Use

ring compressor to install piston assemblies into cylinder bore.

Make sure raised

markings on connecting rods and caps face the front (flywheel) end.

Also, if arrow is

stamped on top of K482 piston, arrow must face direction of crankshaft rotation (clockwise

when facing flywheel).

Arrow stamping on early models only.

Gently push piston into bore

with hammer handle

--

do not pound into position.

STEP

7

-

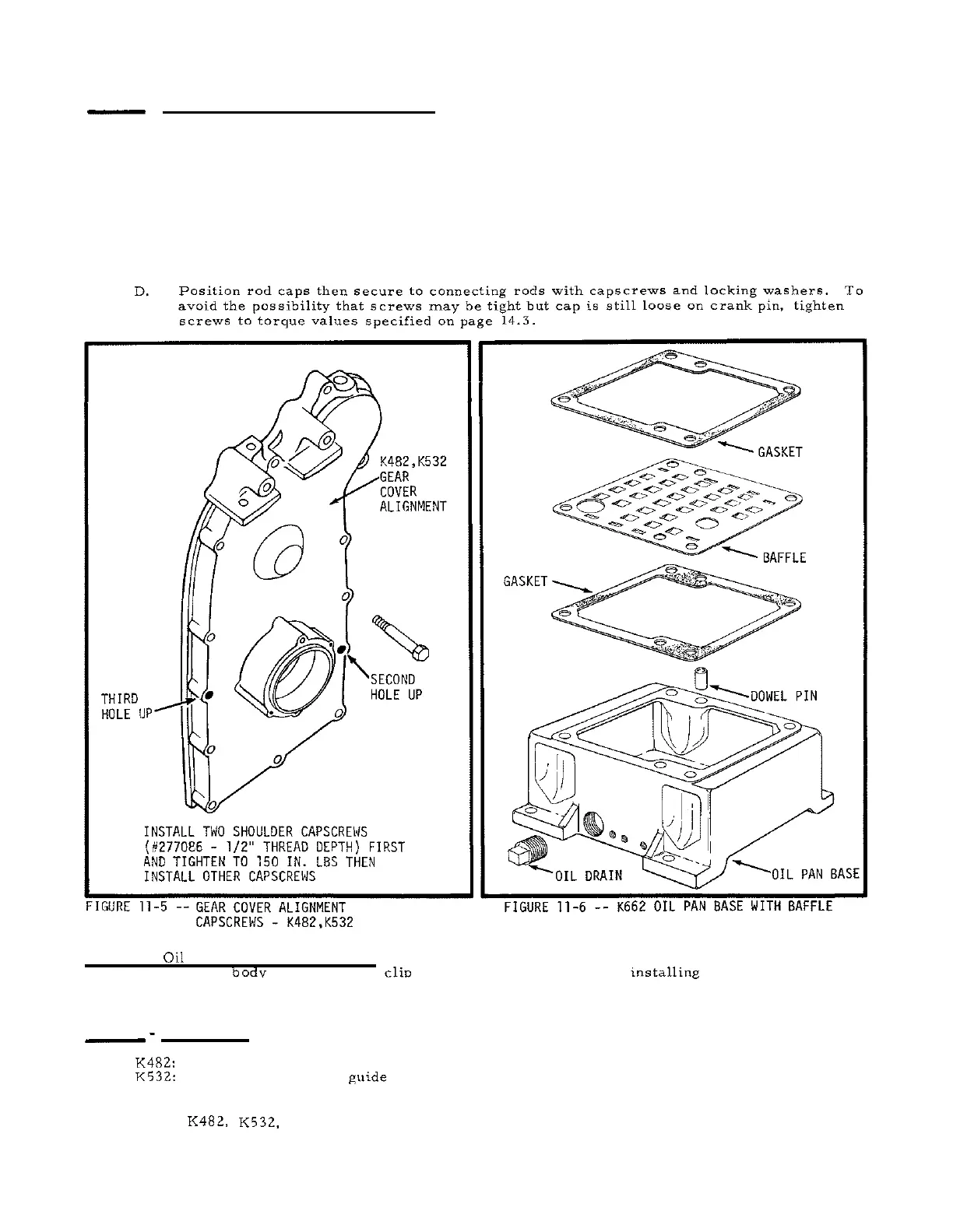

Oil Screen and Oil Pan Base:

Connect oil screen or strainer to oil pump body.

Thread oil

tube into

body then assemble clip and strainer to tube. After installine strainer, position new

-

.

oil pan gasket,

place dowel, then secure oil pan to block with oil pan capscrews.

If pan baffle

is used, position gasket

on

each side of baffle.

STEP

8

-

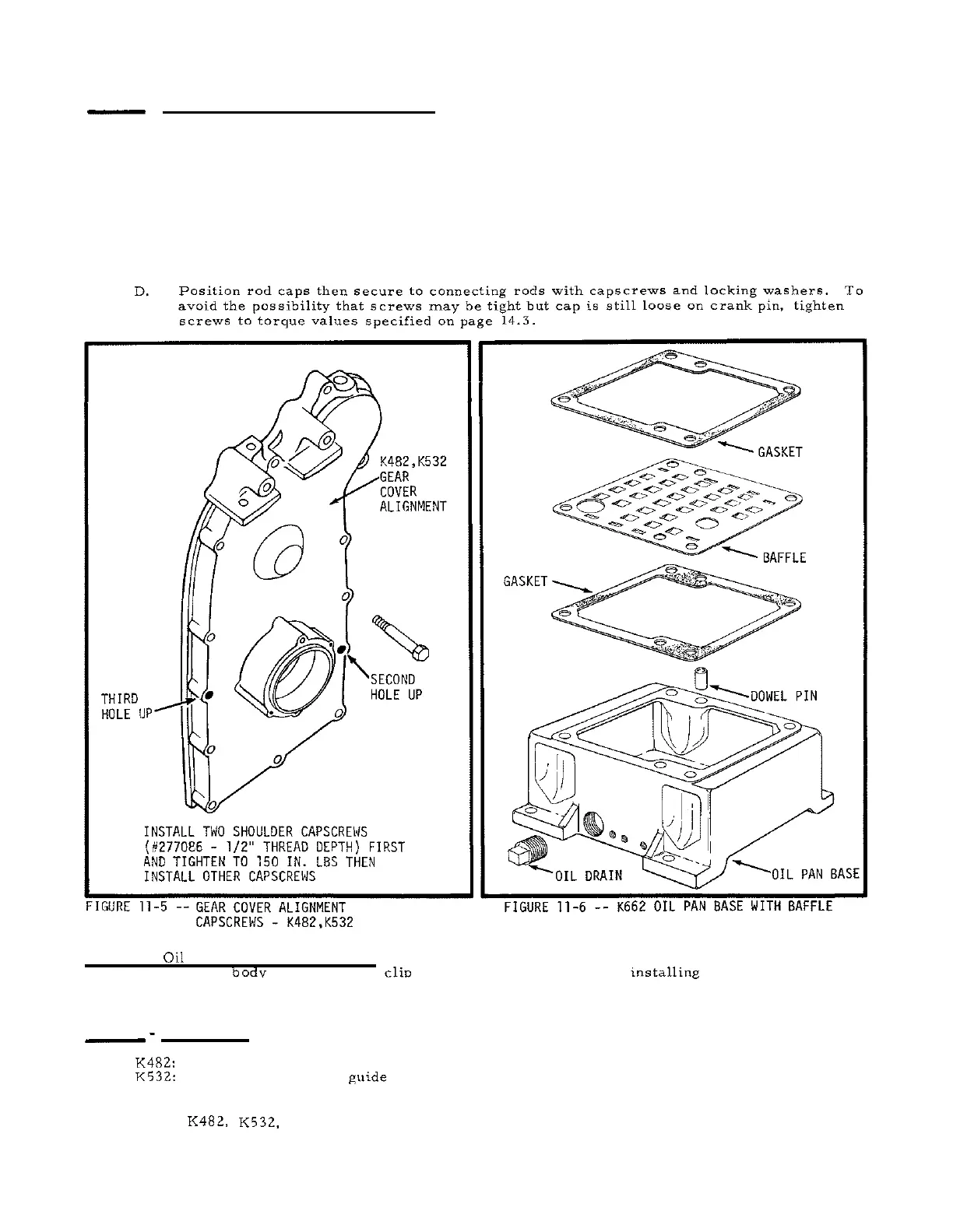

Gear Cover:

-

K482: Grease

seal to make

it slide easier then install new oil seal in cover, position

new

cover

K532: gasket then carefully guide cover over shaft.

Gently work cover when installing to prevent

damage to the seal.

Before inserting capscrews, position the blower housing support then

secure cover and support to block with the capscrews.

When installing gear cover on

K482,

K532,

make sure that the two shoulder screws are installed in locations shown

above to align cover.

Misalignment will cause stator damage.

11.4

Loading...

Loading...